Method for switching positive roller and negative roller of working roll

A technology of work rolls and working methods, applied in the field of metallurgy, can solve the problems of strip deviation, broken strip, impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

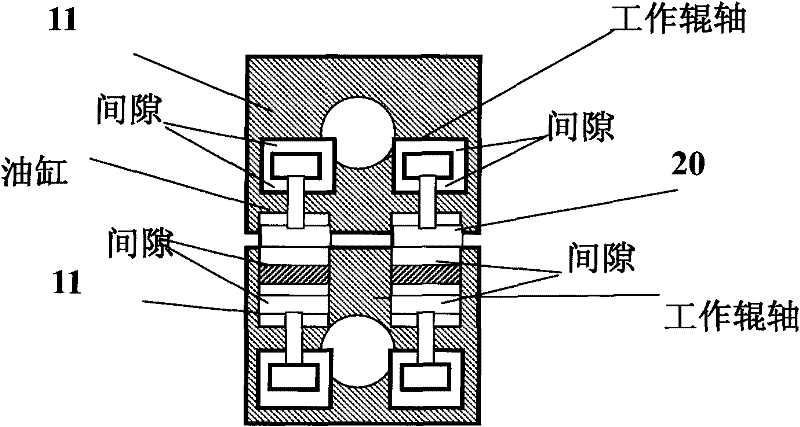

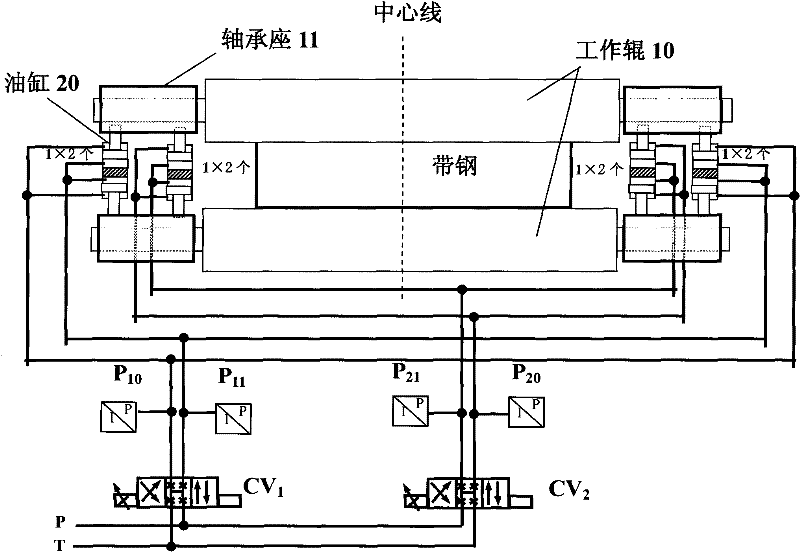

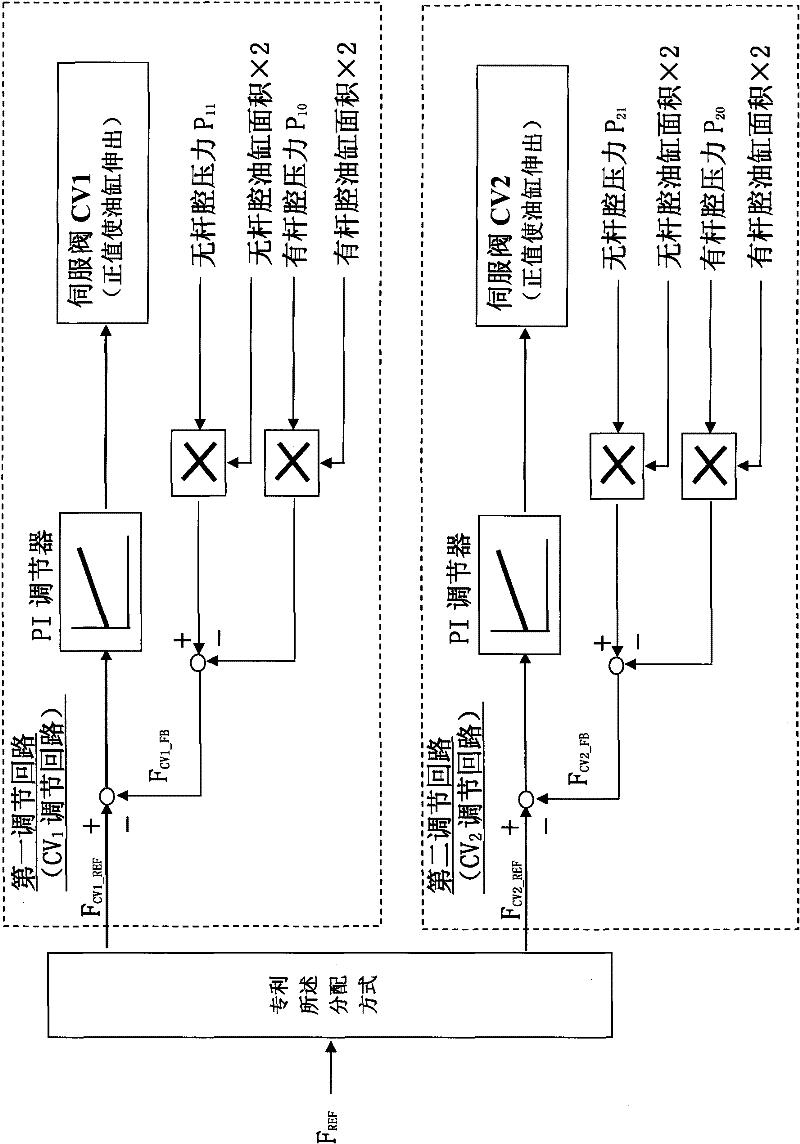

[0054] The positive and negative bending roll switching method of the working rolls of the present invention, a plurality of bending roll oil cylinders are set between the left and right sides of the upper and lower work rolls, and in order to facilitate the roll change, the bearing blocks and the bending roll oil cylinders are movable connections, There is a gap between the cylinder head of the roll bending cylinder and the T-shaped groove in the roll housing; the center line of the work roll is symmetrical, and the bending cylinders on the left and right sides of the work roll are divided into two groups, and each group of bending cylinders is set Independent roll bending regulator, each group of bending cylinders is controlled by its own independent roll bending regulator and servo valve.

[0055] like figure 2 As shown, four bending oil cylinders are respectively arranged on the left and right sides of the work roll 10, the two bending oil cylinders on the left outer side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com