Oil removal releaser

A releaser, positive surface technology, applied in chemical instruments and methods, grease/oily substance/float removal devices, flotation water/sewage treatment, etc. Pollution, water environment pollution and other problems, achieve good economic and social benefits, reduce labor intensity, and overcome the effects of equipment downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

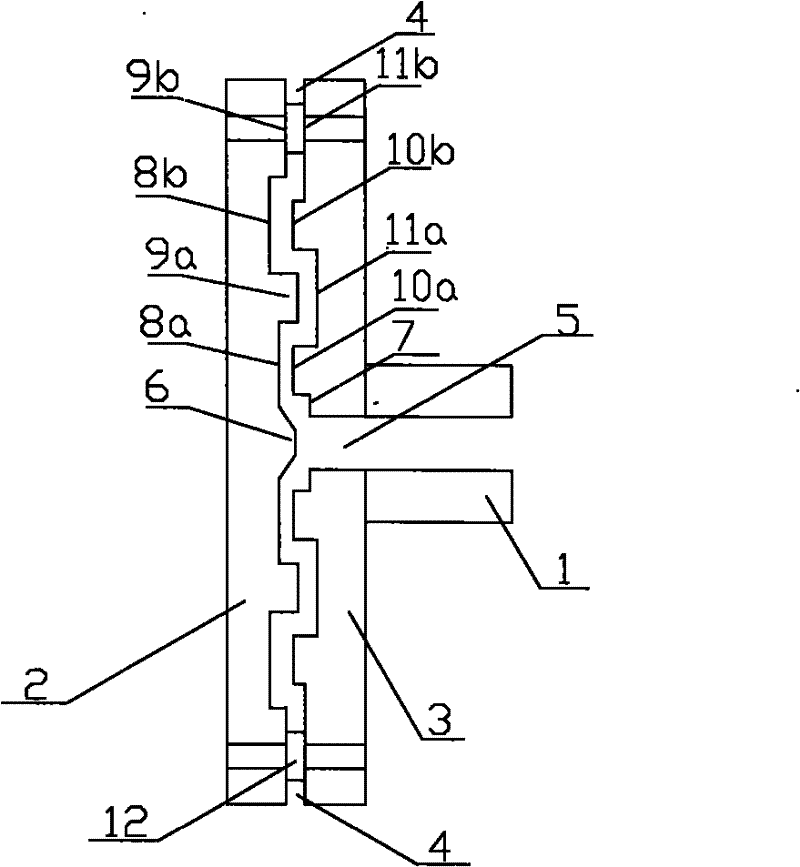

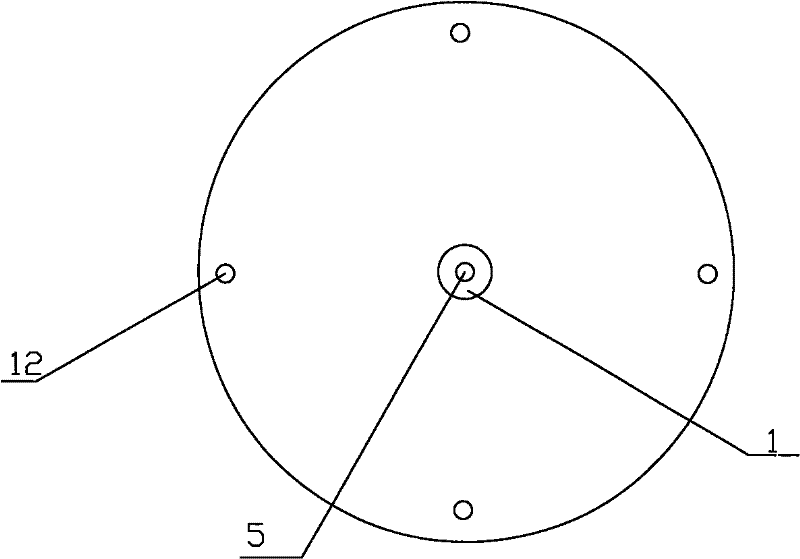

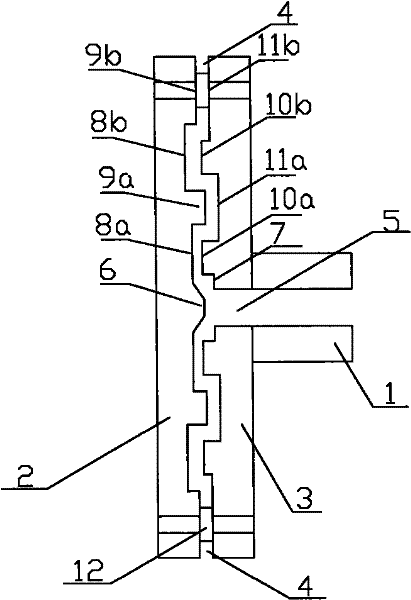

[0013] The present invention will be further explained below in conjunction with the accompanying drawings.

[0014] The invention discloses a degreasing releaser. The degreasing releaser is in the shape of a perfectly circular disc, including a positive surface 3 and a negative surface 2. The center of one side of the negative surface 2 is a conical protrusion 6, which is outward from the conical protrusion 6. There are two annular grooves 8 and two annular bosses 9 concentric with the conical protrusion 6, the grooves 8 and the bosses 9 are arranged alternately, the innermost circle is a groove 8a, and the negative surface 2 The other side is horizontal; the center of the positive surface 3 is a circular groove 7, and from the circular groove 7 there are two annular bosses 10 and two annular bosses 10 concentric with the circular groove 7. Grooves 11, the grooves 11 and the bosses 10 are arranged alternately, the innermost circle is the bosses 10a, the center of the circular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com