Series-wound type poly-generation technology for coal chemical industry

A polygeneration and series-type technology, which is applied in the chemical industry, organic chemistry, petroleum industry, etc., can solve the problems of lower product synthesis rate and failure to play the purpose of polygeneration, and achieve the effect of improving energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

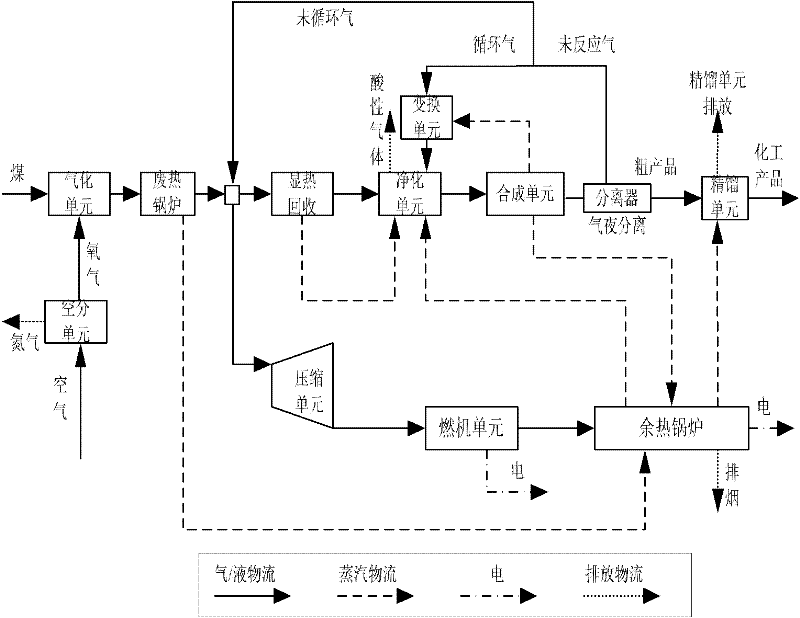

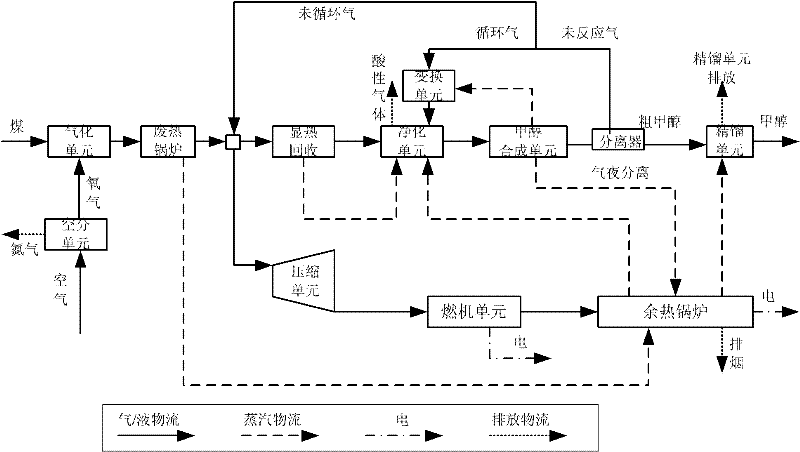

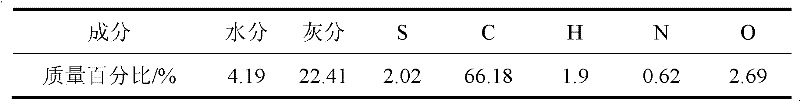

[0018] Embodiment 1: adopt the complex coal chemical industry series polygeneration technique of the inventive method, will figure 1 The project in which chemical products are replaced by methanol is the flow chart of complex coal chemical series methanol-power polygeneration system, as shown in figure 2 shown. The raw coal is Shanxi Jincheng No. 9 anthracite, and the basic components of the coal are shown in Table 1.

[0019] Table 1 Composition of Shanxi Jincheng No. 9 Anthracite Coal

[0020]

[0021] Gasification process: choose Shell gasification process. According to the temperature required for the reaction of the gasifier (>1000°C to ensure liquid slag removal), under the condition of optimal thermal efficiency, select the inlet parameters of the gasifier as shown in Table 2 below:

[0022] Table 2 Proportion of gasification agent

[0023]

[0024] Purification and steam conversion process: according to the complex coal chemical industry series polygeneratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com