Freezer oil and work fluid composition for freezer

A technology of refrigerating machine oil and working fluid, which is applied in the direction of lubricating compositions, petroleum industry, chemical instruments and methods, etc., and can solve problems such as poor lubrication, inability to obtain compatibility between refrigerant and refrigerating machine oil, and capillary blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

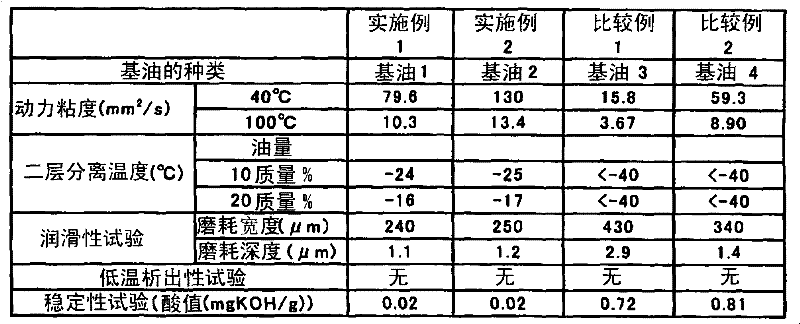

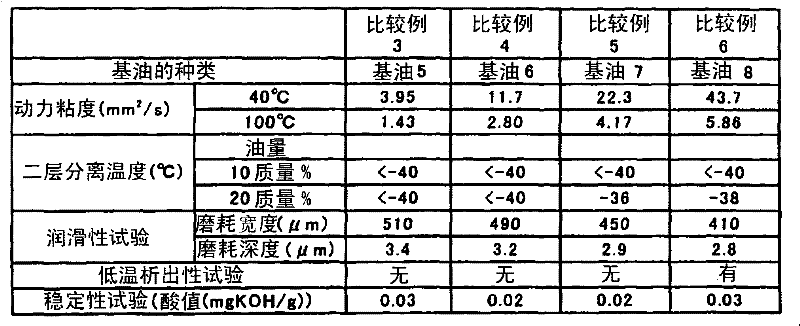

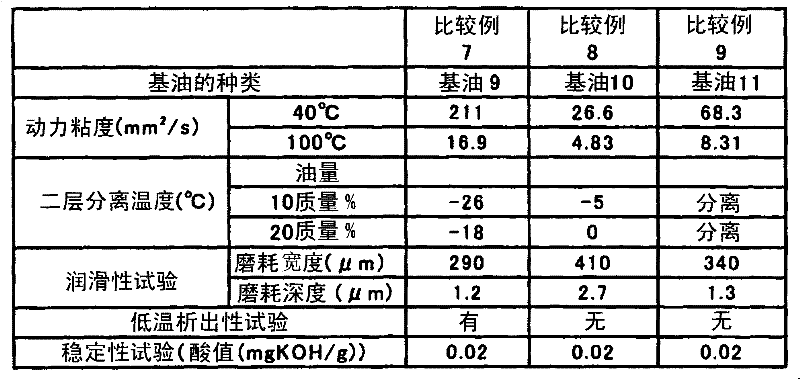

Embodiment 1~2 and comparative example 1~9

[0096] In Examples 1 to 2 and Comparative Examples 1 to 9, sample oils were prepared using base oils 1 to 11 shown below, respectively. Properties (kinetic viscosity at 40°C and 100°C, total acid value) of the obtained sample oils are shown in Tables 1-3.

[0097] (base oil)

[0098] Base oil 1: Hexaester of dipentaerythritol and 2-methylpentanoic acid

[0099] Base oil 2: mixture of dipentaerythritol and fatty acid (50 mol% of 2-methylvaleric acid, 50 mol% of 2-ethylbutyric acid)

[0100] Base oil 3: tetraester of pentaerythritol and n-valeric acid

[0101] Base oil 4: Hexaester of dipentaerythritol and n-valeric acid

[0102] Base oil 5: diester of neopentyl glycol and 2-methylpentanoic acid

[0103] Base oil 6: triesters of trimethylolpropane and 2-methylpentanoic acid

[0104] Base oil 7: Tetraester of pentaerythritol and 2-methylpentanoic acid

[0105] Base oil 8: tetraester of pentaerythritol and 2-ethylbutyric acid

[0106] Base oil 9: Hexaester of dipentaerythrito...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com