Multi-curvature radius twisted steel pipe and making method thereof

A manufacturing method and a technology of radius of curvature are applied in the production of this kind of bending and torsion steel pipe, in the field of bending and torsion steel pipe with multiple curvature radii. Problems such as poor arc smooth quality, to achieve the effect of saving labor hours, beautiful appearance and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

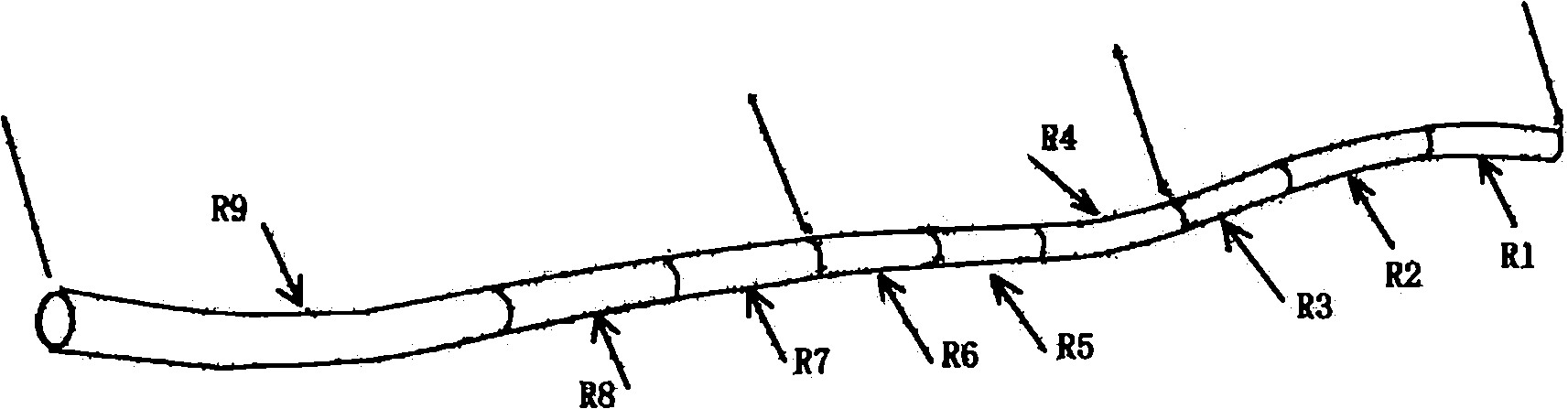

[0044] Such as figure 1 The shown multi-curvature radius twisted steel pipe is composed of nine segments with small curvature radii on different planes.

[0045] This embodiment also discloses a method for manufacturing the above-mentioned curved and twisted steel pipe with multiple curvature radii. The specific steps of the method are as follows:

[0046] (a) Use computer to deepen the design of multi-curvature-radius bent-torsion steel pipes to make an overall model;

[0047] (b) Divide the overall model into small segments according to a single curvature radius, and each curvature radius is divided into a small segment. In this embodiment, a single bent-torsion steel pipe has 9 small segments: R1, R2, R3, R4, R5, R6, R7, R8, R9;

[0048] (c) Divide every three small sections into a partition, and place one partition on a steel pipe for processing; thus, three partitions are formed: R1, R2, R3 are one partition; R4, R5, R6 are one Partition; R7, R8, R9 are one partition; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com