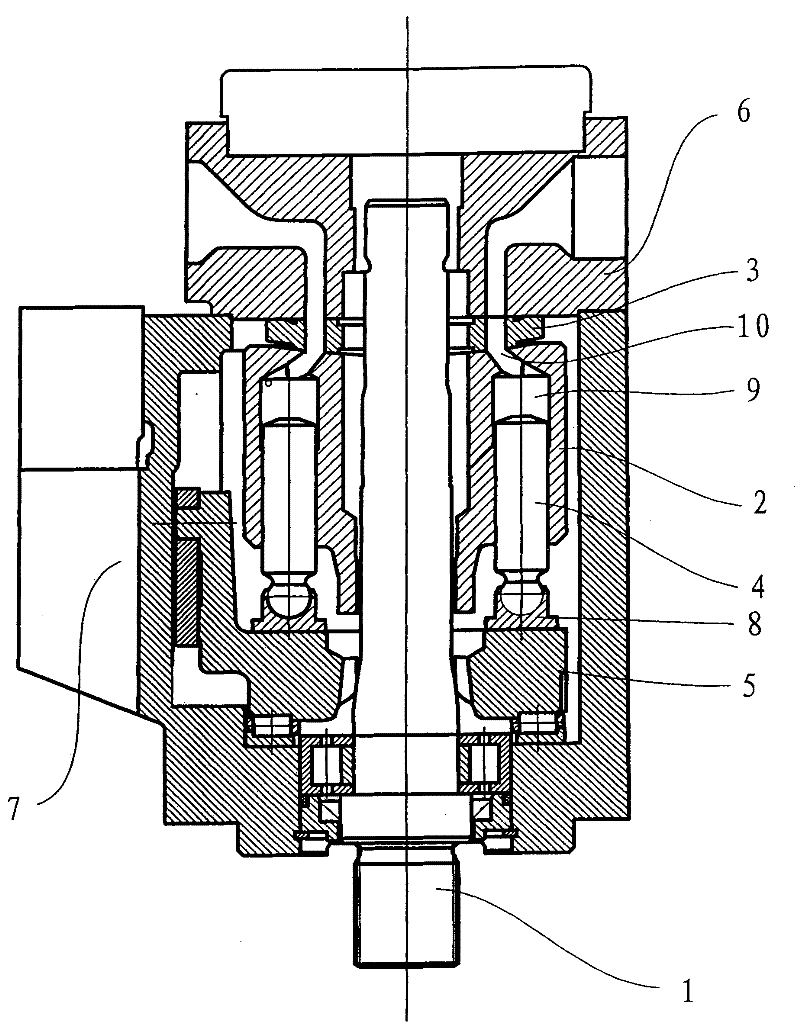

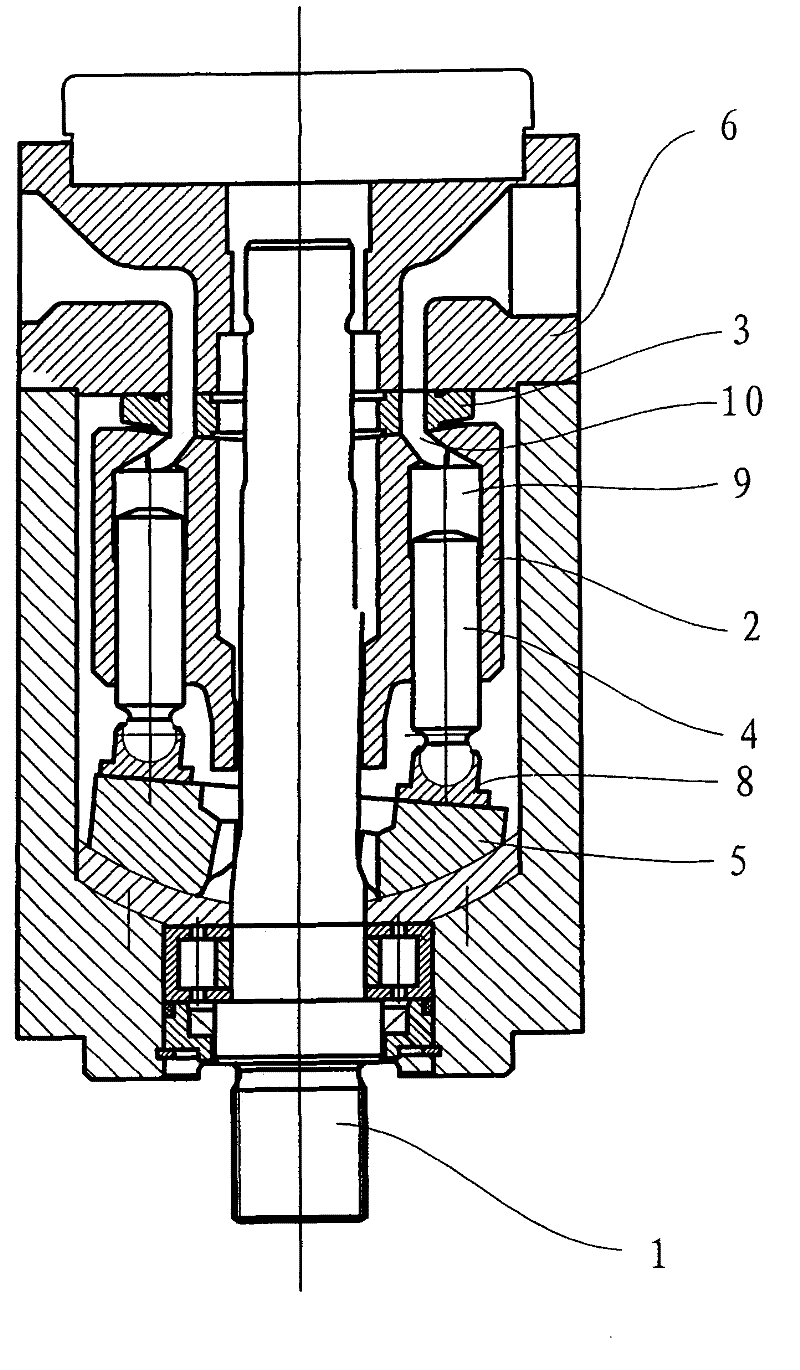

Axial plunger pump with double rows of cylinder holes and cylinder bodies

A technology of axial plunger pump and cylinder hole, which is applied to multi-cylinder pumps, parts of pumping devices for elastic fluids, pumps, etc., and can solve the problem of aggravated wear of sliding shoes and wobble plates, plungers and cylinder holes, Increase the diameter of the cylinder bore, increase the size of the cylinder pump body, etc., to achieve the effects of prolonging the life, increasing the frequency of oil discharge, and increasing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Image 6 , Figure 7 Shown is a structural diagram of Embodiment 1 of the double-row cylinder bore cylinder block of the present invention. In this embodiment, the number of waist-shaped through holes 23 in the double-row cylinder bore cylinder block 20 is equal to the two rows of cylinder bores 21, 22, that is, each cylinder hole 21 or 22 is correspondingly provided with a waist-shaped through hole 23, and the bottoms of the cylinder holes 21, 22 are provided with connecting holes 24, 25. The distribution positions of the waist-shaped through holes should correspond to the positions of the semicircular arc distribution holes on the distribution plate.

[0040]Usually, the diameters of the cylinder bores arranged on two circles with different radii are not equal, and the diameter of the cylinder bore 21 on the large diameter circle is greater than the diameter of the cylinder bore 22 on the small diameter circle. The waist-shaped through-holes 23 are evenly distribut...

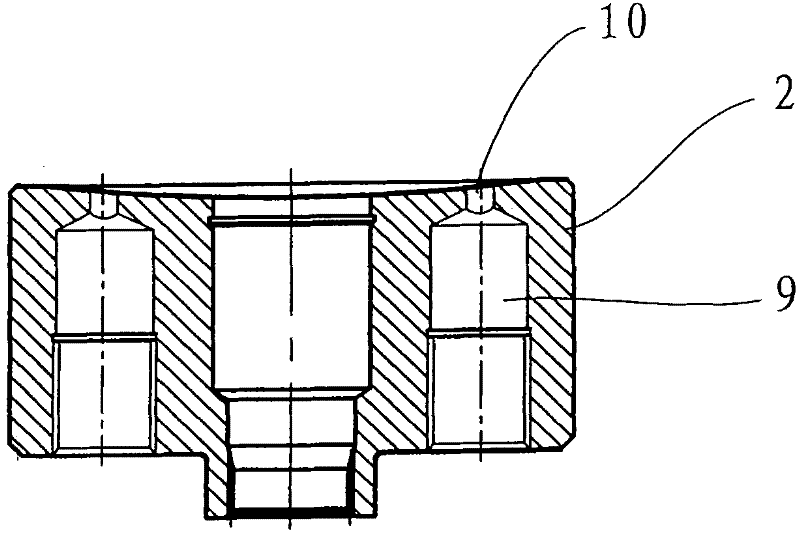

Embodiment 2

[0044] Figure 8 , Figure 9 Shown is another embodiment of the structure of the cylinder 20' in the axial piston pump of the double-row cylinder bore cylinder of the present invention. The difference from Embodiment 1 is that the number of waist-shaped through holes 23' is equal to one row of cylinder bores The bottoms of adjacent cylinder holes 21', 22' on every two circumferences are provided with connecting holes 24' and 25' communicating with the same waist-shaped through hole 23'. Compared with the first embodiment, the advantage is that the number of waist-shaped through holes is reduced, and the processing man-hours are saved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com