Gas-bag type band-type brake

A brake and airbag technology, applied in the field of components of the drive device, can solve the problems of increased operating cost, high noise, increased operating cost, etc., and achieve the effects of reducing maintenance cost, expanding the scope of application, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

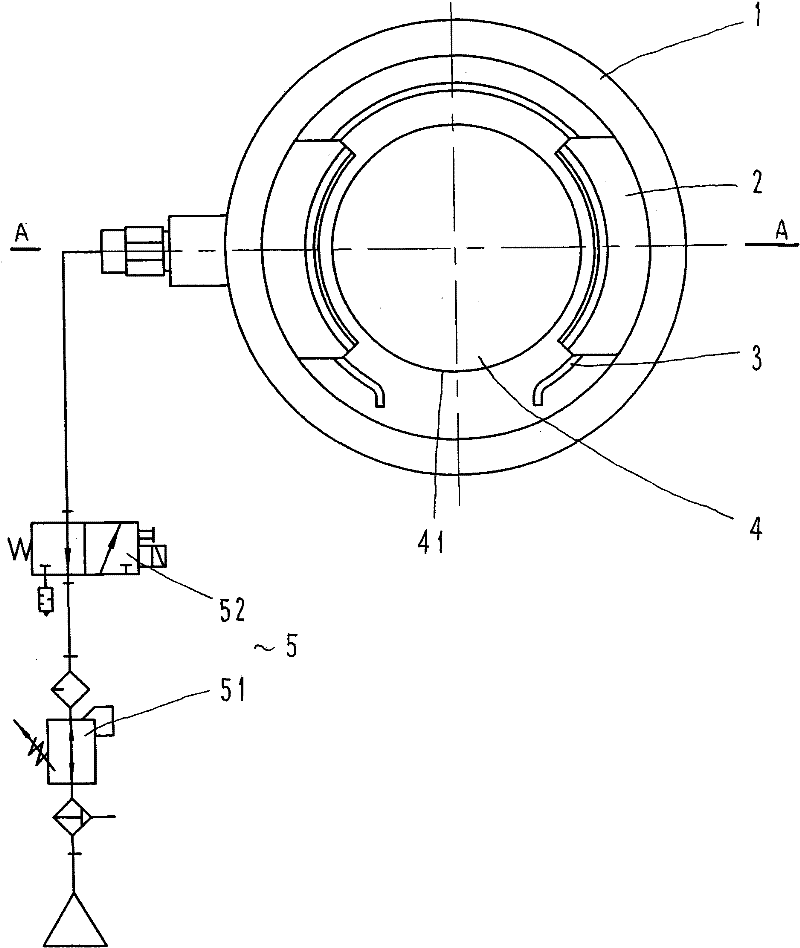

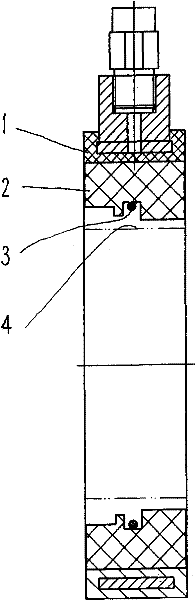

[0013] refer to figure 1 , the airbag type brake includes an airbag assembly 1, a friction plate 2, a return spring 3, a friction wheel 4 and a pneumatic control system 5.

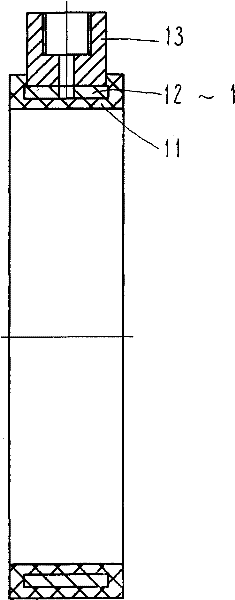

[0014] Air bag assembly 1, such as figure 1 , 2 , 3, and 4, the assembly includes a working chamber 10, an air bag 11, a retaining ring 12 and a joint 13, wherein:

[0015] Working chamber 10, such as Figure 4 As shown, it is composed of the inner annular surface 112 of the airbag 11, the left side wall 115, the right side wall 116 and the inner annular surface 121 of the stop ring 12. When the non-braking state, the working chamber 10 is only the inner annular surface 121 and the joint gap between the annulus 112 in the cavity;

[0016] The airbag 11 is an annular capsule with an inner cavity, which can be made of rubber or plastic, and its inner wall surface 111 is a circular through hole, and the inner wall surface 111 is the surface in contact with the friction plate 2. 112. The inner surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com