Two-phase flow cooling device for IGBT

A cooling device and phase flow technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of unstable temperature control, prone to failure, poor heat dissipation efficiency, etc., to improve the effect of buffering and release, easy to assemble and adjustment, the effect of improving work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

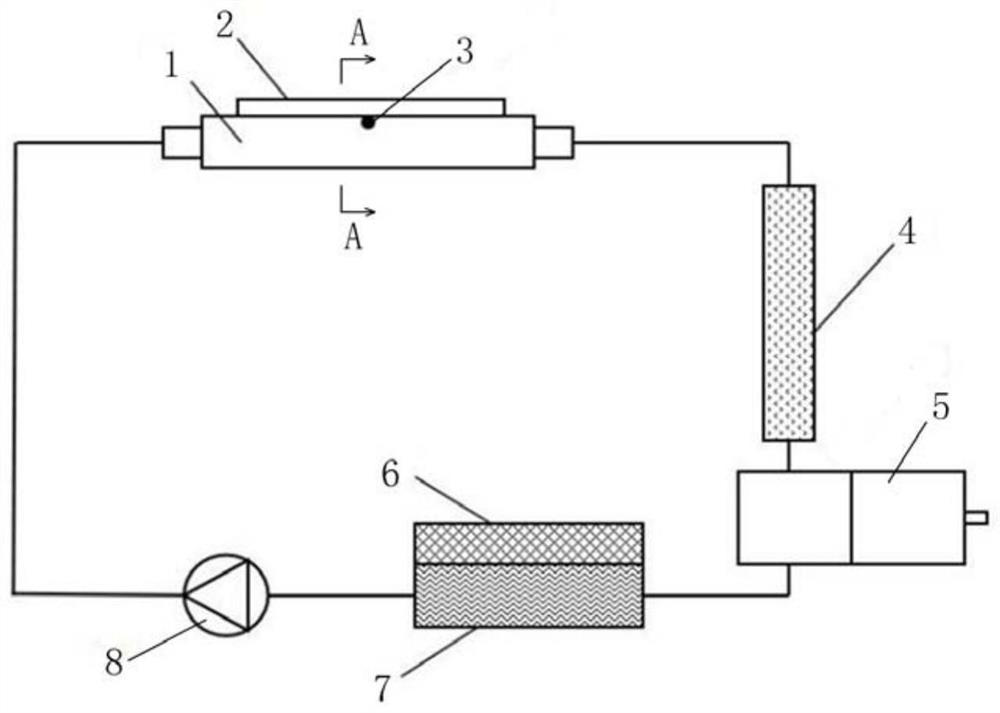

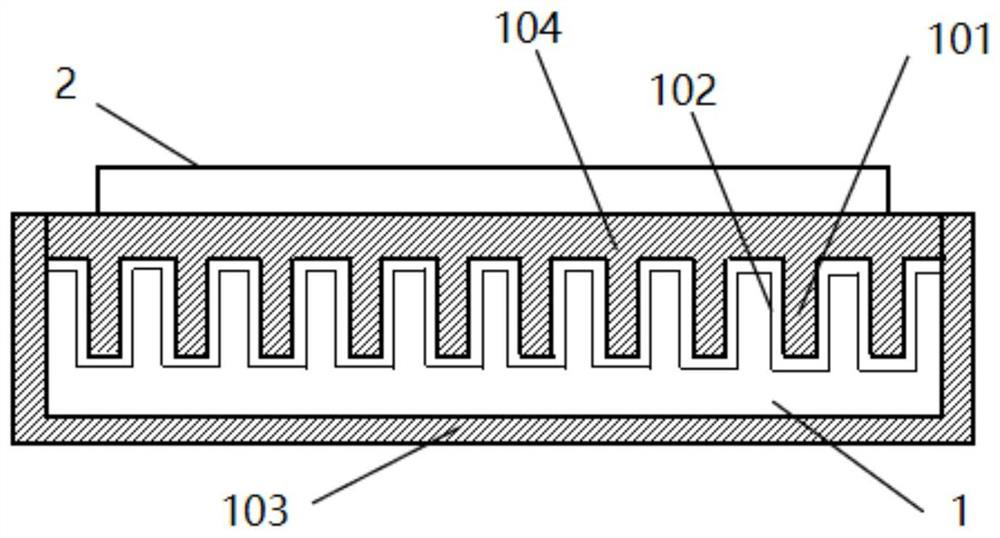

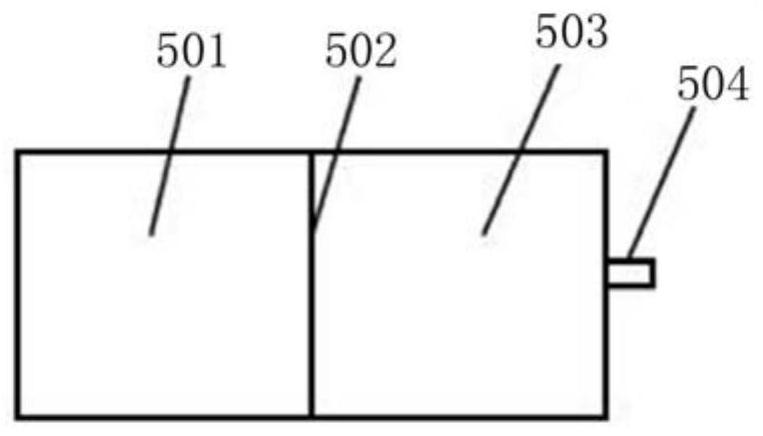

[0031] Such as figure 1 As shown, this embodiment provides a two-phase flow cooling device for IGBT, which is aimed at the IGBT in a certain charging pile. The two-phase flow cooling device includes a heat exchange cold plate module 1 , a mixed flow pipe 4 , a liquid storage buffer tank 5 , a radiator 7 and a power pump 8 . The heat exchange cold plate module 1, the mixed flow pipe 4, the liquid storage buffer tank 5 and the radiator 7 are sequentially connected in an annular manner to form a cooling circulation flow channel, and the power pump 8 is connected to the cooling circulation flow channel, which is specifically arranged in the heat exchange cold plate module 1 and radiator 7. The IGBT2 is welded on the heat exchange cold plate module 1 .

[0032] The cooling cycle process of this example is: the liquid refrigerant with a certain degree of supercooling is transferred to the heat exchange cold plate module 1 through the power pump 8, and is partially vaporized in the...

Embodiment 2

[0043] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that there are multiple heat exchange cold plate modules 1 arranged side by side, and the two ends of the multiple heat exchange cold plate modules 1 are connected to the cooling circulation flow through the bus bar 9 Road, preferably four in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com