A self-optimizing flash spray cooling system for electronic devices

A circulating cooling system and electronic device technology, applied in the direction of fluid circulation arrangements, machines that use refrigerant evaporation, superheaters, etc., can solve the problems of significant cooling effect, refrigerant waste, environmental pollution, etc., and achieve omission of heating devices, The effect of improving heat exchange efficiency and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In conjunction with the following drawings, the present invention is further described by examples.

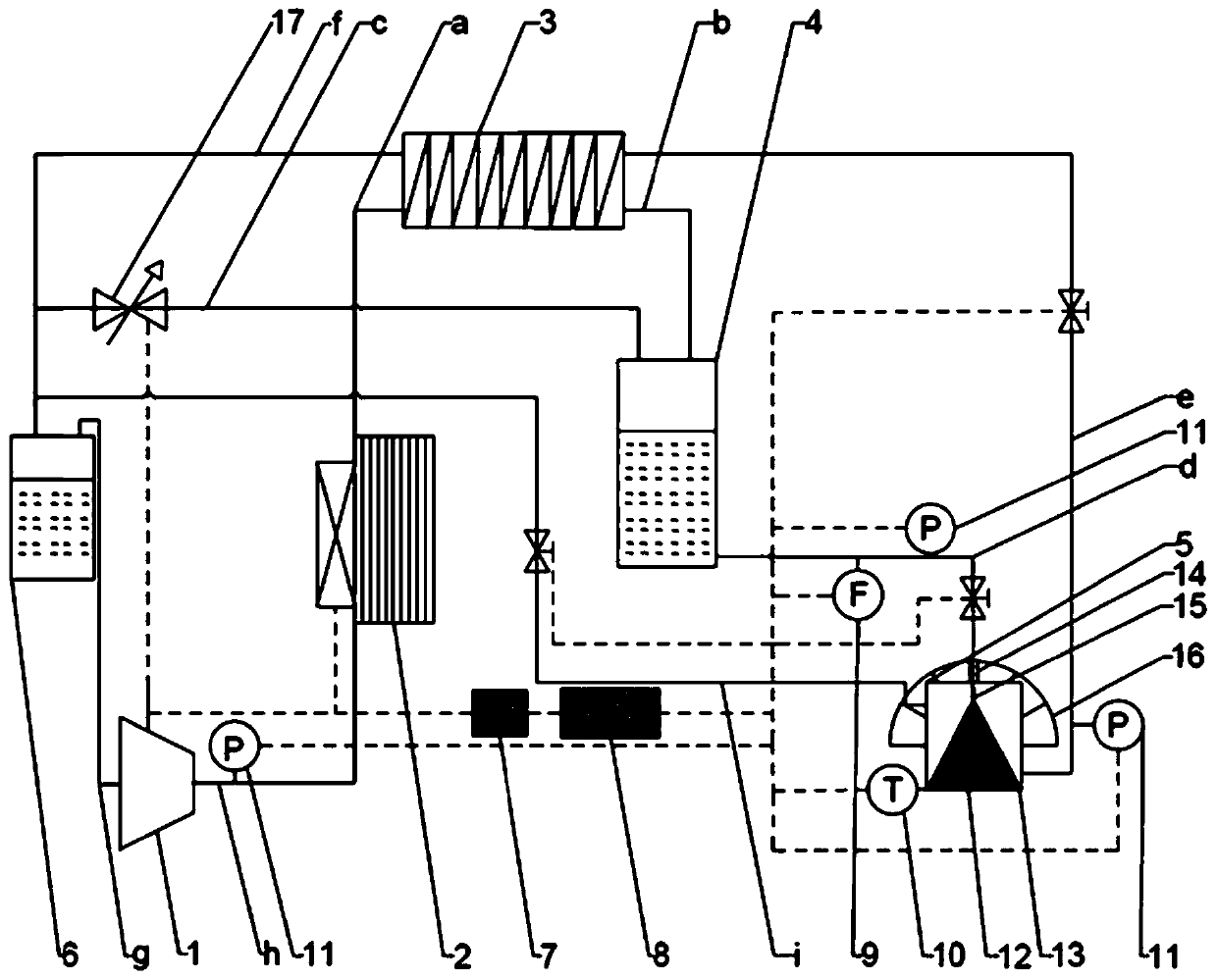

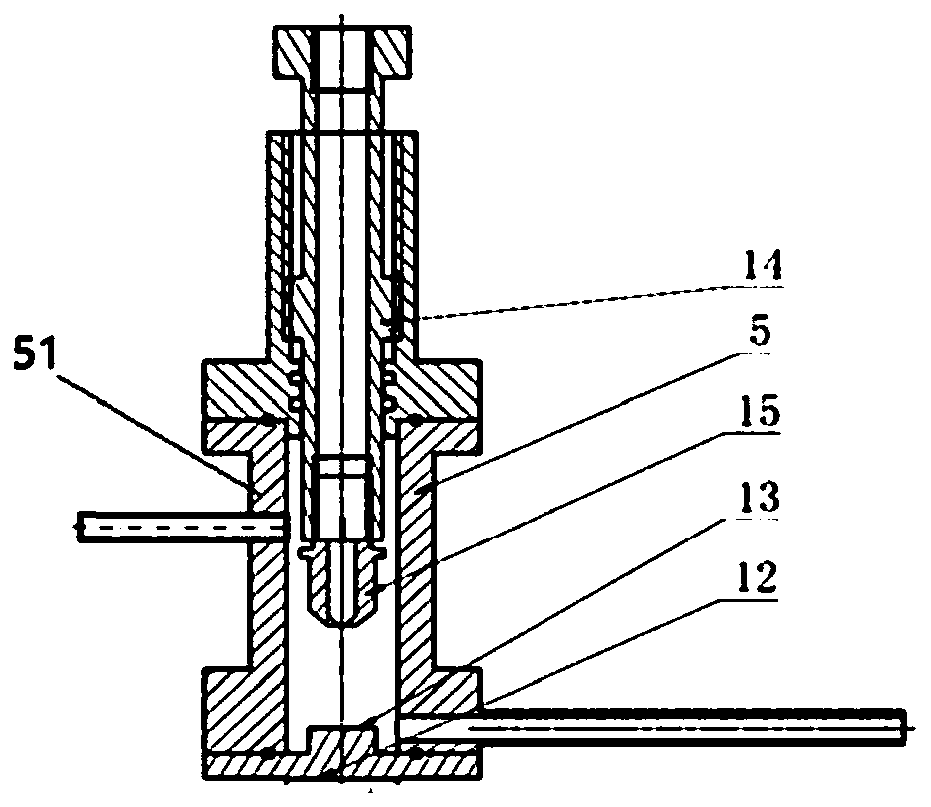

[0032] see figure 1 As shown, the present invention has a self-optimizing feature of the flash spray circulation cooling system for electronic devices, including a compressor 1, a forced air-cooled condenser 2, a regenerator 3, a liquid storage tank 4, a spray chamber 5, and a gas-liquid separator 6. Flow regulation bypass c and control system.

[0033]Compressor 1 is a variable frequency rotor compressor; the outlet of compressor 1 is connected to the inlet of condenser 2 through pipe h, the outlet of condenser 2 is connected to the inlet of the first channel of regenerator 3 through pipe a, and the first channel of regenerator 3 The outlet of a channel is connected to the inlet of the liquid storage tank 4 through the pipeline b, the lower outlet of the liquid storage tank 4 is connected to the inlet of the spray chamber 5 through the pipeline d, and the lower liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com