Self-circulating submerged jet phase-change liquid-cooling heat dissipation device inside the blade server shell

A blade server and heat dissipation device technology, which is applied in the direction of using liquid cooling for modification, cooling/ventilation/heating modification, and instrumentation, etc. It can solve the problem of preventing direct contact between liquid refrigerant and the surface of the heat source, unable to maintain a constant temperature of the heating element, and unable to replace it efficiently Heat and other problems, to achieve the effect of heat dissipation, heat exchange efficiency improvement, and increase of refrigerant disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to more clearly understand the above objects, features and advantages of the present application, the present application will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be noted that the embodiments of the present application and the features of the embodiments may be combined with each other unless there is conflict.

[0026] In the following description, many specific details are set forth to facilitate a full understanding of the present application. However, the present application can also be implemented in other ways different from those described herein. Therefore, the protection scope of the present application is not subject to the following disclosure. Restrictions to specific embodiments.

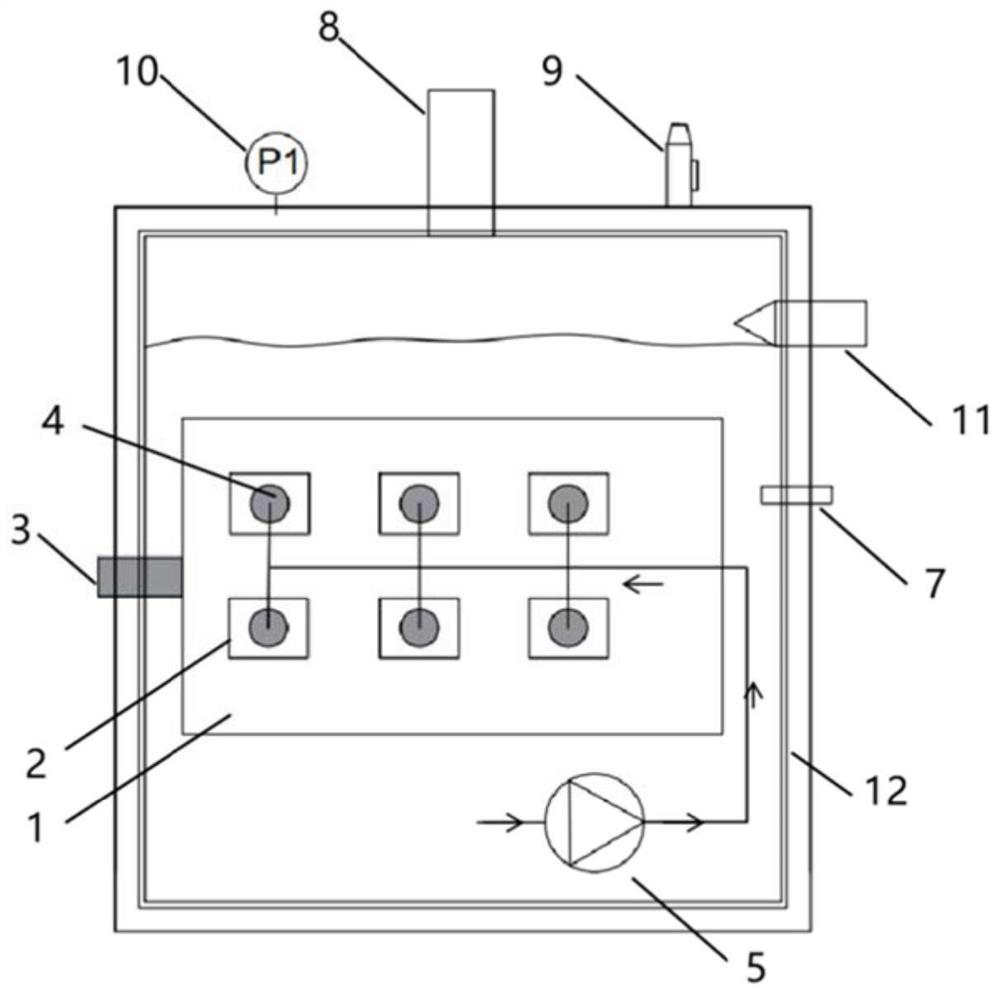

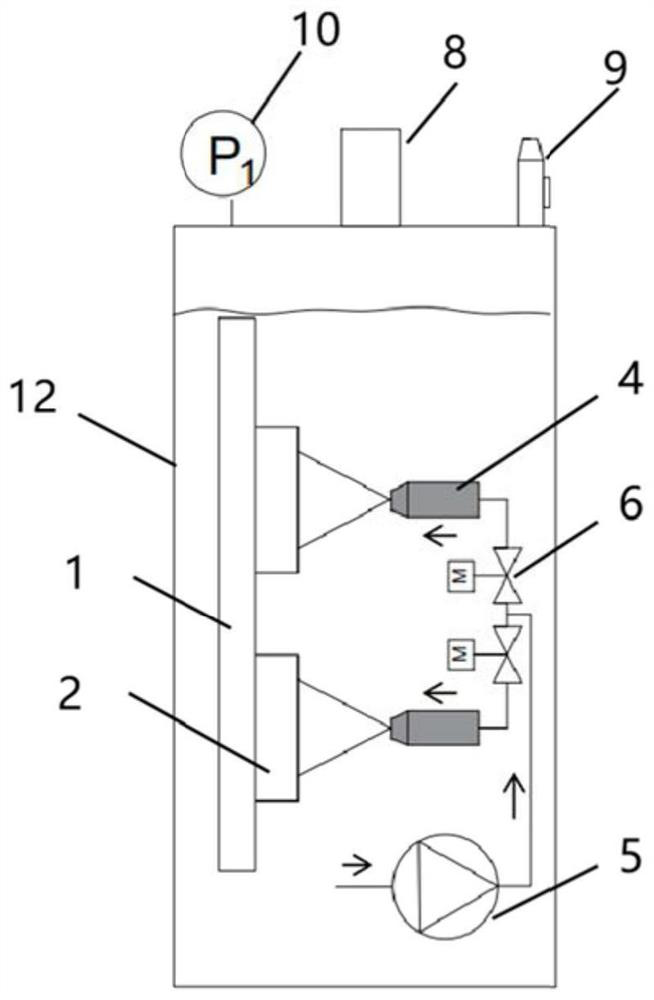

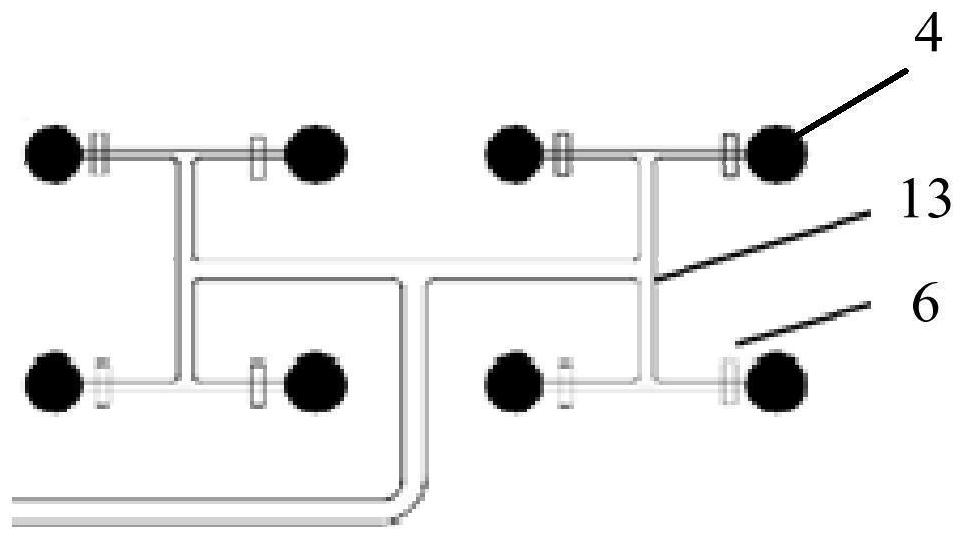

[0027] like figure 1 As shown in the figure, this embodiment provides a self-circulating submerged jet phase change liquid-cooling heat dissipation device inside the blade server shell. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com