Device for stabilizing drill pipe in damping pipe of directional drilling and using method thereof

A stabilizing device and inner drill pipe technology, applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problem of being unable to install again, and achieve the effect of small workload, improved stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

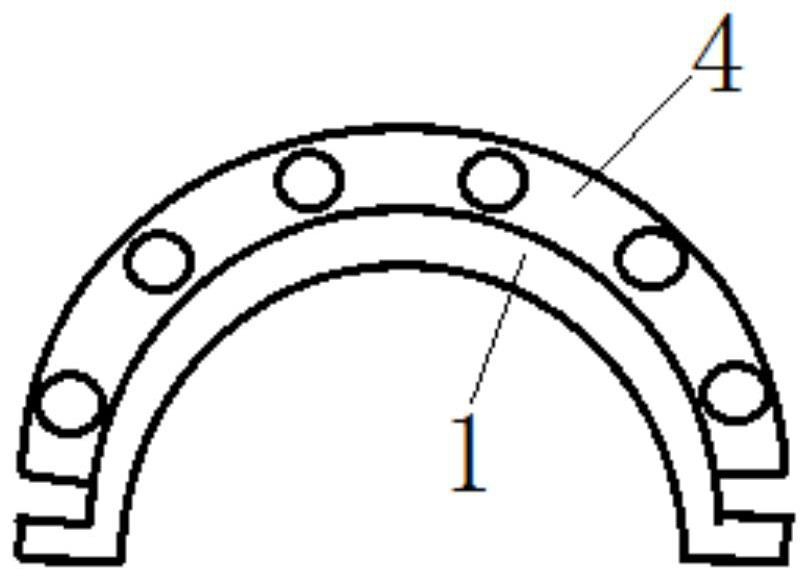

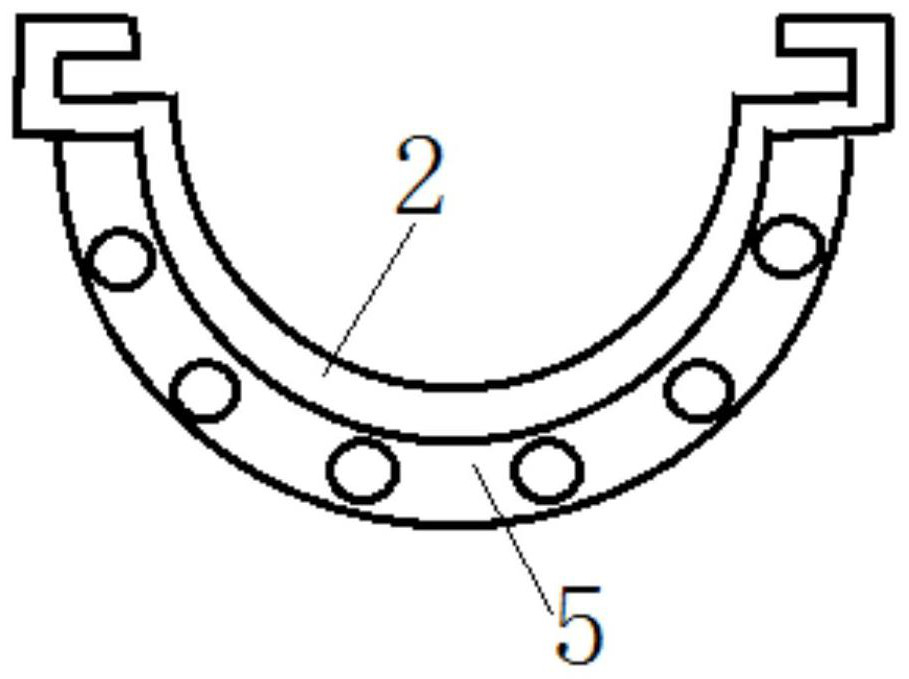

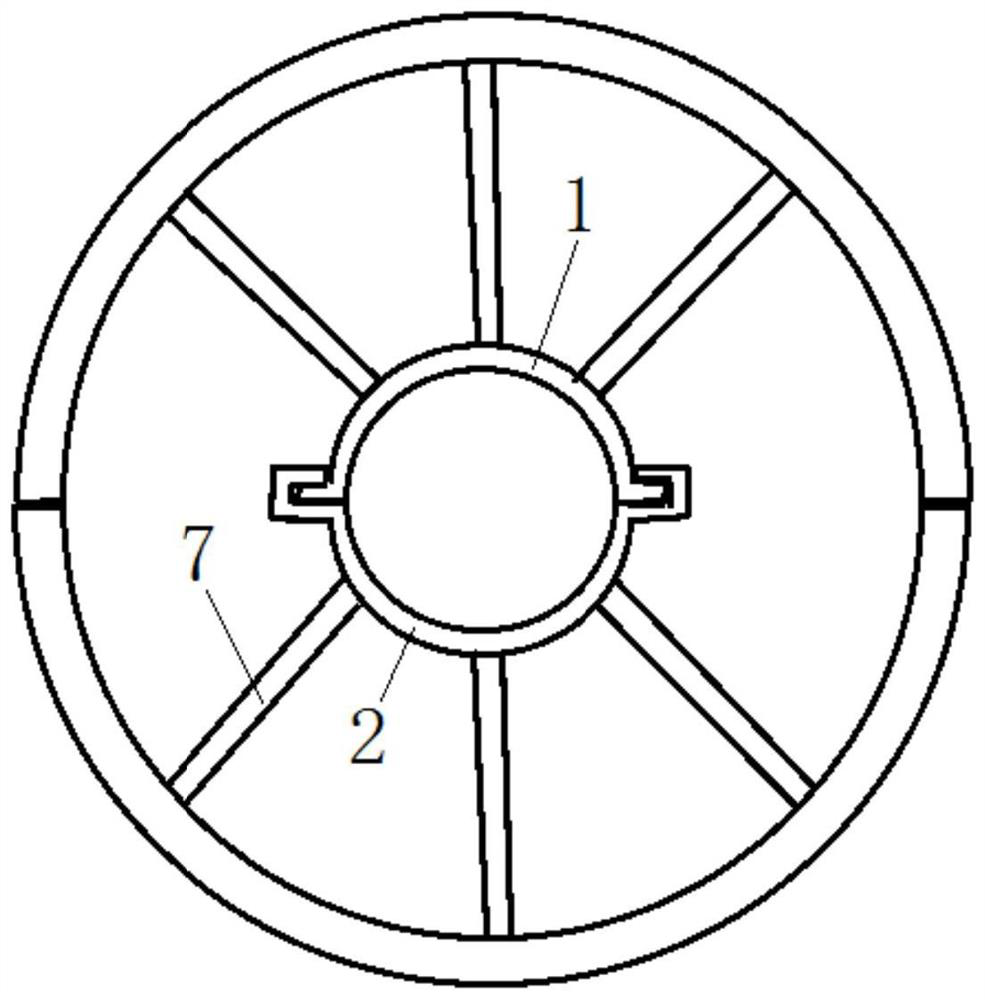

[0052] as attached Figure 1-5 As shown, the present embodiment provides a drill pipe stabilizing device for directional drilling and ramming pipes, comprising several sections of drill pipe support pipes and an axial fixing mechanism 6, the inner diameter of the drill pipe support pipes is greater than the outer diameter of the drill pipe; The support pipes are all sleeved on the outside of the drill pipe and placed in the ramming pipe; flanges are used to fix the support pipes of adjacent sections of drill pipe.

[0053] The drill pipe support pipe includes a first stabilizer 1, a second stabilizer 2, several radial support mechanisms, two first flanges 4 and two flanges 5; the cross-section of the first stabilizer 1 and the second stabilizer 2 Both are semi-circular; the first stabilizer 1 and the second stabilizer 2 are spliced to form a hollow circular pipe structure, and the joint of the first stabilizer 1 and the second stabilizer 2 is a detachable structure; the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com