Method for checking enamel scale explosion resistance of cold-rolled steel plate

An inspection method and technology of cold-rolled steel plates, applied in the field of inspection, can solve the problems of expensive measuring instruments and unsuitable for popularization and use, and achieve the effects of easy operation, high sensitivity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for testing the anti-enamel scale explosion performance of cold-rolled steel plates, the steps are as follows:

[0023] 1) Use sandpaper to grind the DC01 cold-rolled steel plate sample with a thickness d of 0.9mm to 400# on both sides, then clean it with acetone, and then clean it with absolute ethanol;

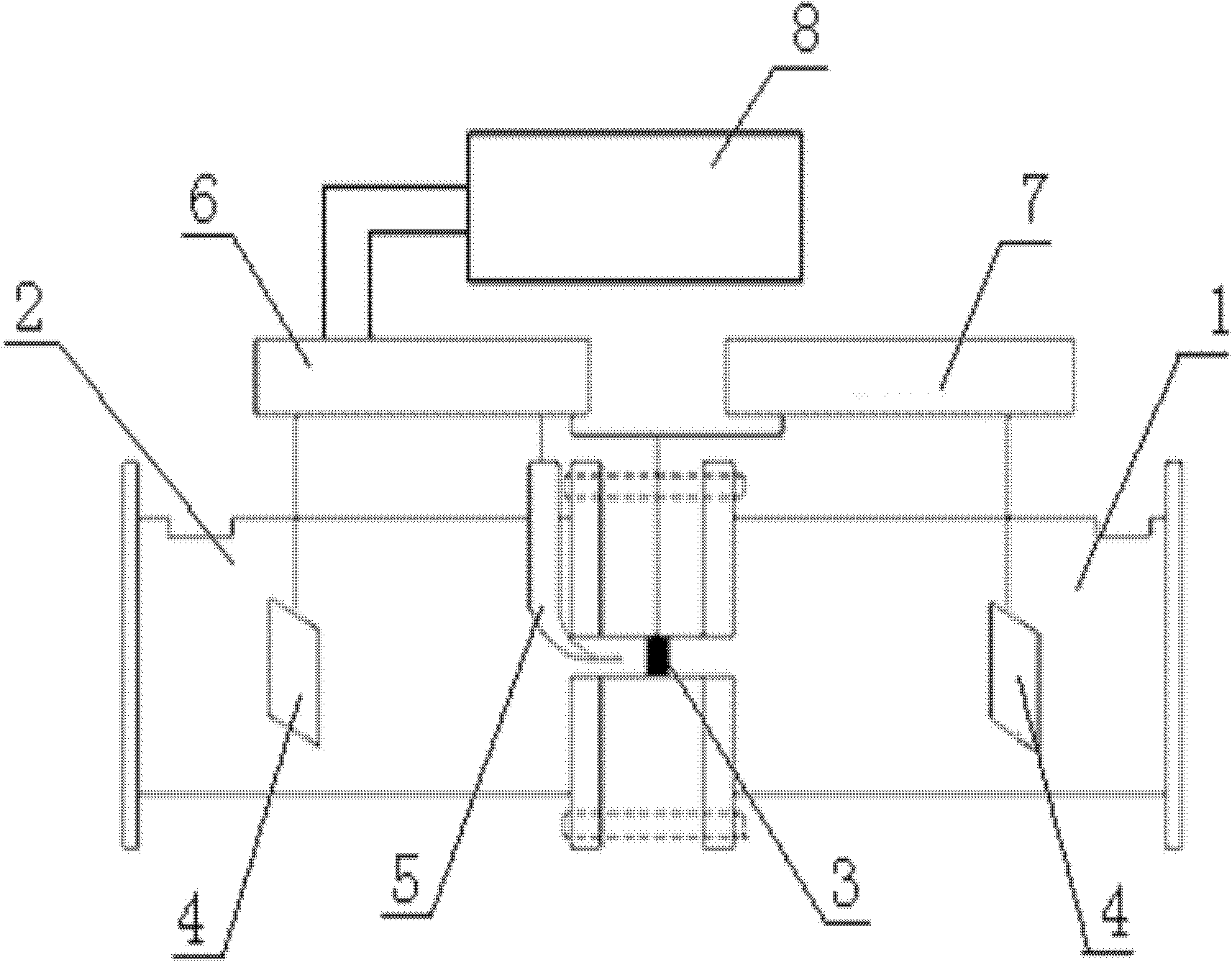

[0024] 2) Fasten the sample between the two electrolytic cells A and B through an O-ring, and the diameter of the contact surface between the sample and the electrolytic cell is 18mm;

[0025] 3) Electrolyte temperature control 30±0.5℃;

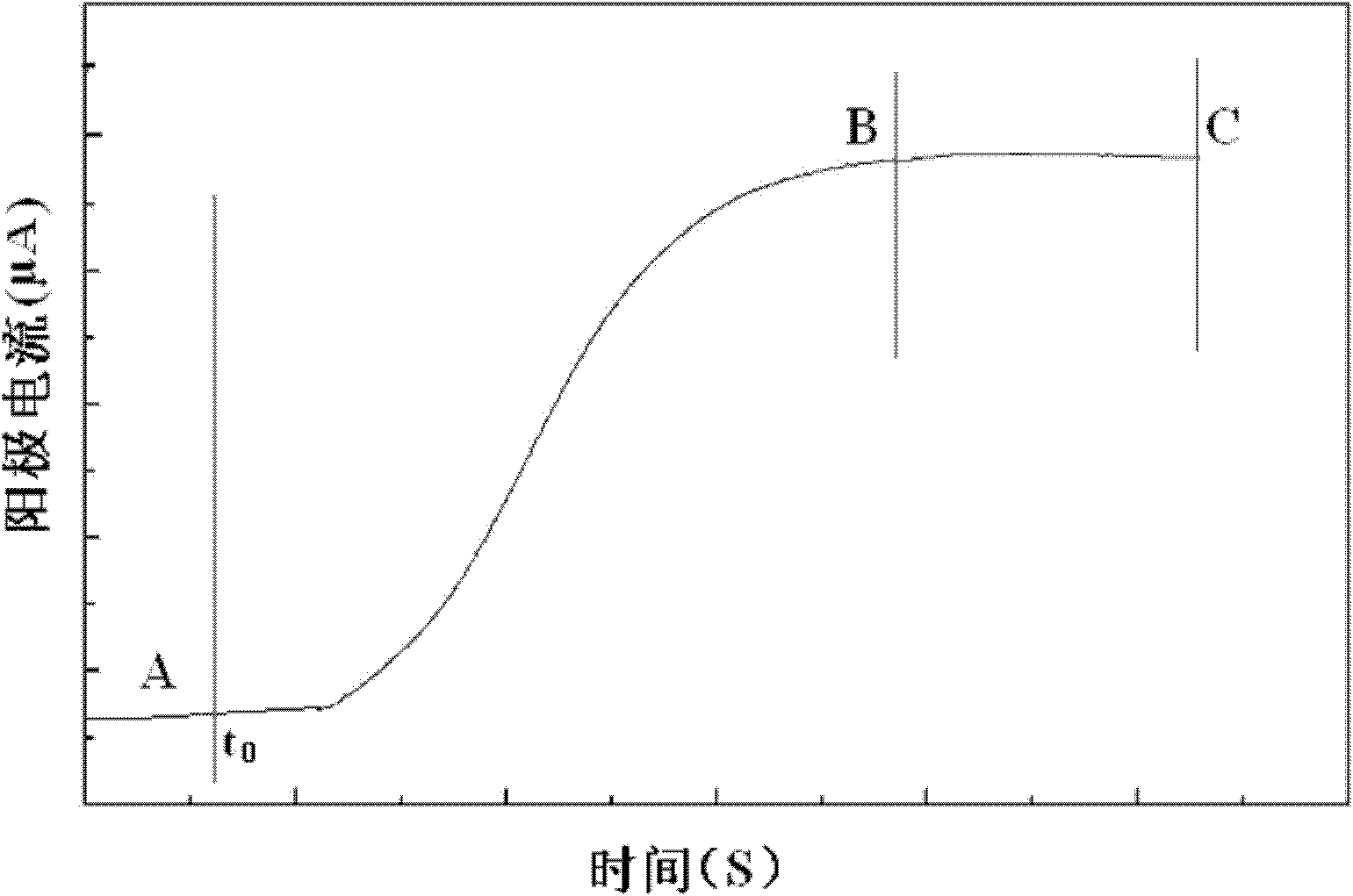

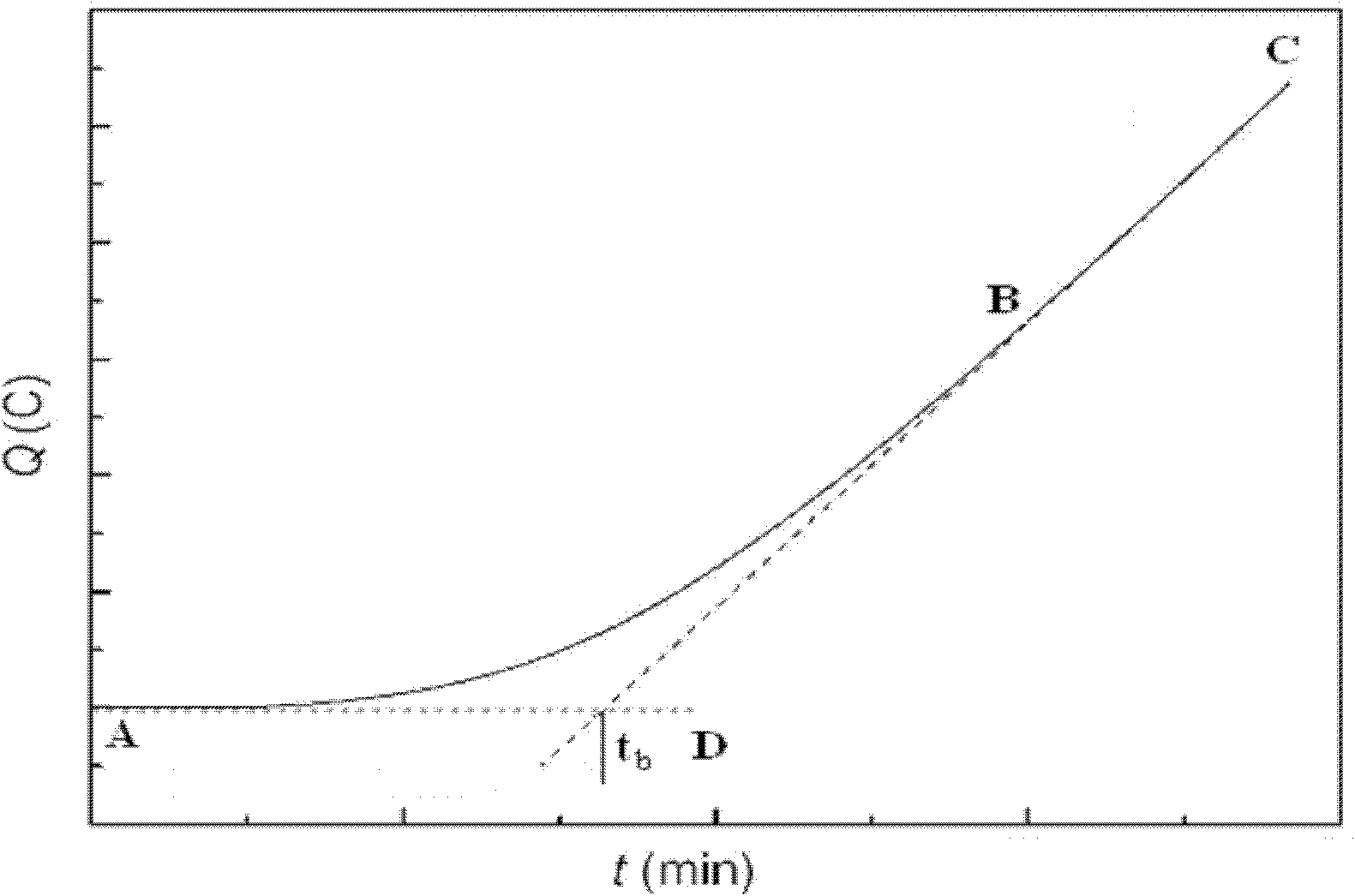

[0026] 4) Pour 0.2mol / L NaOH aqueous solution into the electrolytic cell B, so that the liquid level exceeds the upper edge of the working part of the sample by 1cm, use the Pt sheet as the cathode and the sample as the anode, and use a potentiostat to keep the sample at 0.2V (vs SCE), while the computer monitors the residual current I in the sample 0 ;

[0027] 5) When the residual current I 0 When it drops below 1.5μA,...

Embodiment 2

[0033] A method for testing the anti-enamel scale explosion performance of cold-rolled steel plates, the steps are as follows:

[0034] 1) Use sandpaper to grind the DC05 cold-rolled steel plate sample with a thickness d of 0.8mm to 400# on both sides, then clean it with acetone, and then clean it with absolute ethanol;

[0035] 2) The sample is fastened between the two electrolytic cells A and B through the O-ring, and the diameter of the contact surface between the sample and the electrolytic cell is 20mm;

[0036] 3) Electrolyte temperature control 30±0.5℃;

[0037] 4) Pour 0.2mol / L NaOH aqueous solution into the electrolytic cell B, so that the liquid level is 1cm higher than the upper edge of the working part of the sample, use Pt wire as the cathode and the sample as the anode, and use a potentiostat to keep the sample at 0.5V (vs SCE), while the computer monitors the residual current I in the sample 0 ;

[0038] 5) When the residual current I 0 When it drops below 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com