Supervisory system for on-site explosive mixing and charging truck

A technology of on-site mixed explosives and supervision system, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of lack of location supervision of on-site mixed explosive vehicles, on-site supervision of explosives consumption supervision, etc., to achieve timely satisfaction and eliminate interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

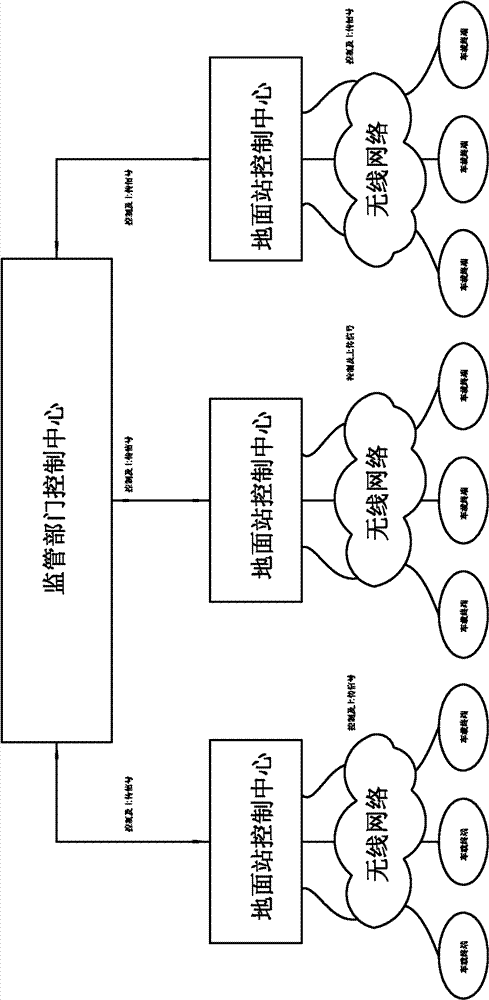

[0070] The specific implementation of the present invention is shown in the accompanying drawings. The on-site mixed explosive vehicle supervision system of the present invention is composed of a vehicle-mounted terminal, a ground station control center and a supervision department control center. The regulatory department control center is connected to multiple ground station control centers through the network, and the ground station control center is connected to multiple vehicle-mounted terminals through the network. Using C / S mode framework. (Such as figure 1 shown)

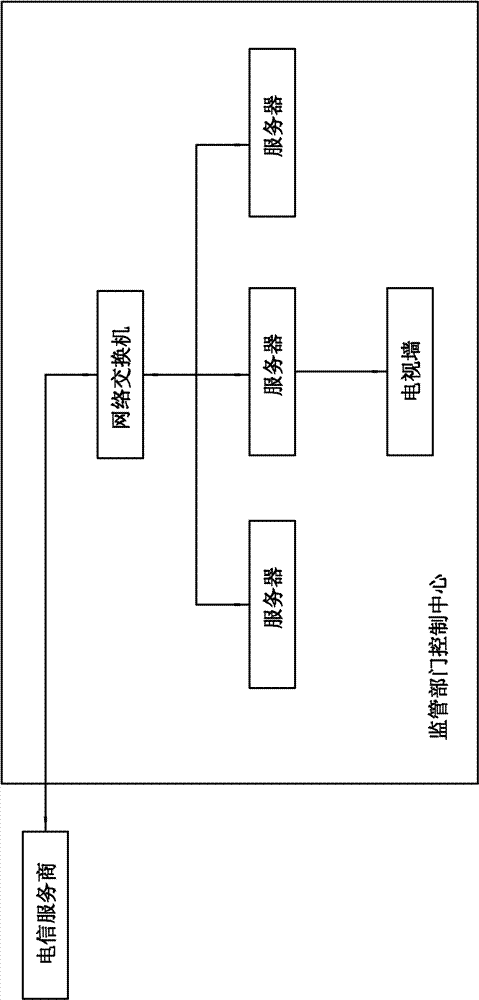

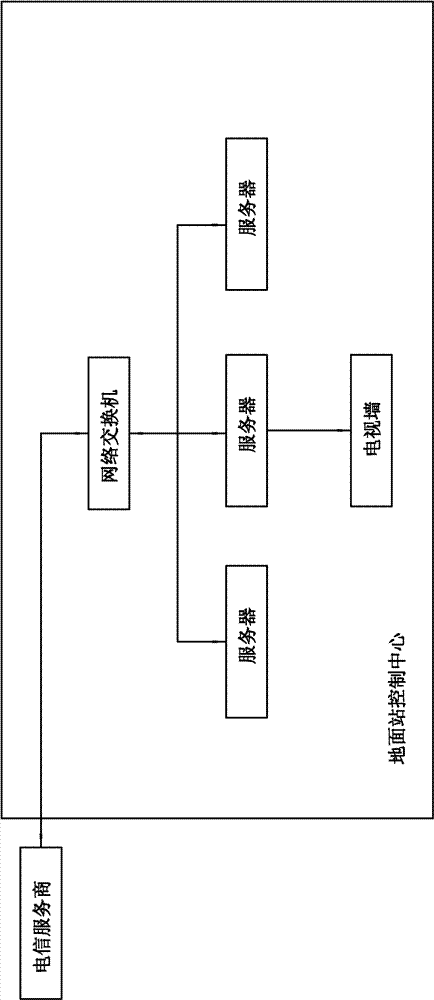

[0071] The ground station control center in the on-site mixed explosive vehicle supervision system of the present invention is to select the Cisco CISCOWS-C2960-24TC-L intelligent switch by the network switch, the server selects the IBMSystemx3650M3 server, and the display selects Weiteng WT-109 video wall, console etc. The network switch is connected to the network of the telecom service provider through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com