Electric lamp with an outer bulb and a built-in lamp and associated production method

An embedded, light bulb technology, applied in discharge lamps, circuits, incandescent lamps, etc., can solve problems such as complex mechanical technology, and achieve the effects of improving energy efficiency, reliable electrical contact, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

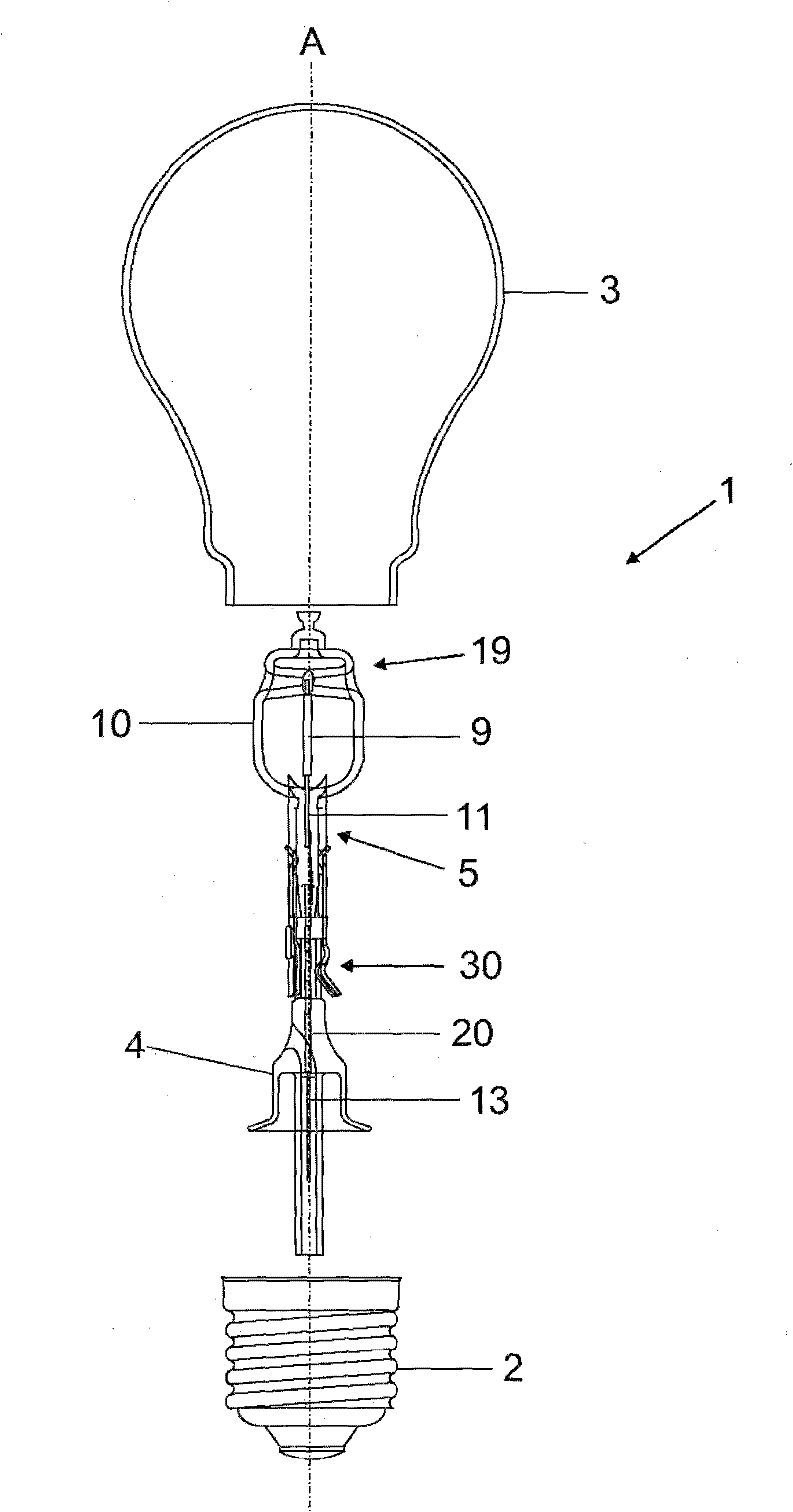

[0027] figure 1 The lamp 1 is shown in its entirety. The outer bulb 3 is held in a commercially available lamp cap 2 of type E27, which has a ceramic base or lamp support and a screw portion fixed thereto. A built-in lamp 19 is arranged in the outer bulb 3 . The built-in lamps are designed as so-called high-voltage halogen incandescent lamps and as lamps known from the prior art. The lamp 1 has a longitudinal axis A. As shown in FIG.

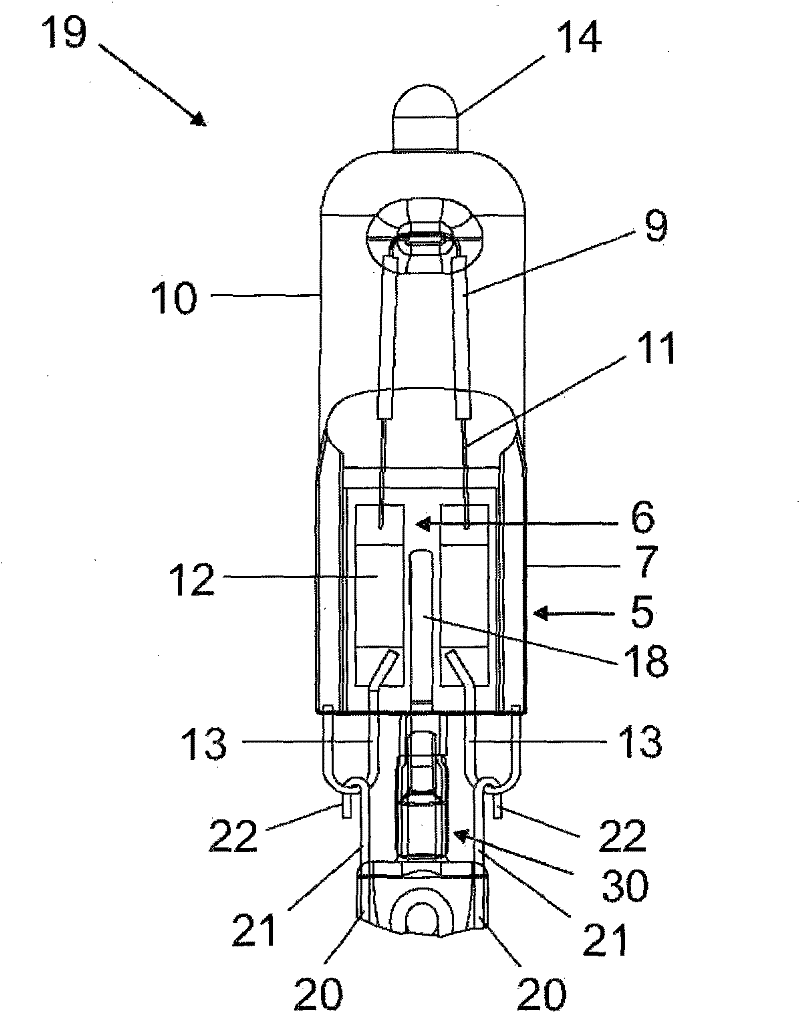

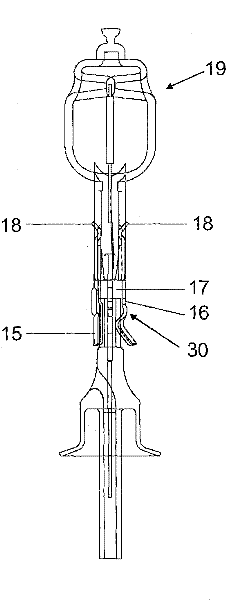

[0028] Recessed light 19 (see also figure 2 with 3 ) is equipped with a single extrusion 5 with two broad sides 6 and two narrow sides 7 . A pin-shaped external power supply line 13 protrudes from the pinch 5 . These external supply lines are bent back in a U-shape on the narrow side of the pinch 5 .

[0029] The built-in lamp 19 is, for example, a one-sided extruded halogen incandescent lamp with the lamp vessel 10 . The illuminant 9 is electrically conductively connected to the base 2 via a power supply line system. The power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com