Wheel mill

A technology of wheel milling and wheel milling, which is applied in grain processing, etc., and can solve problems such as difficult assembly and maintenance, heavy load on the main shaft bearing, and throwing out of parts, and achieve the effects of convenient assembly and maintenance, small main shaft load, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

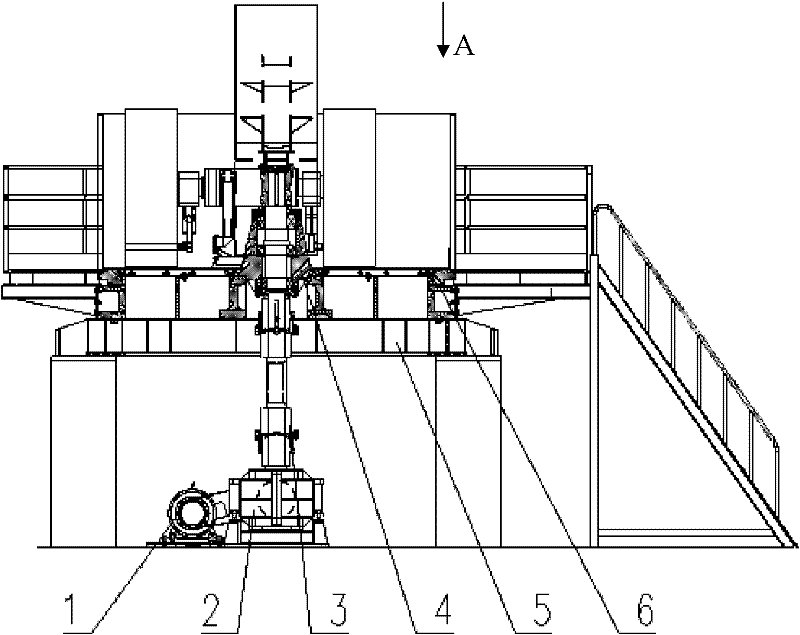

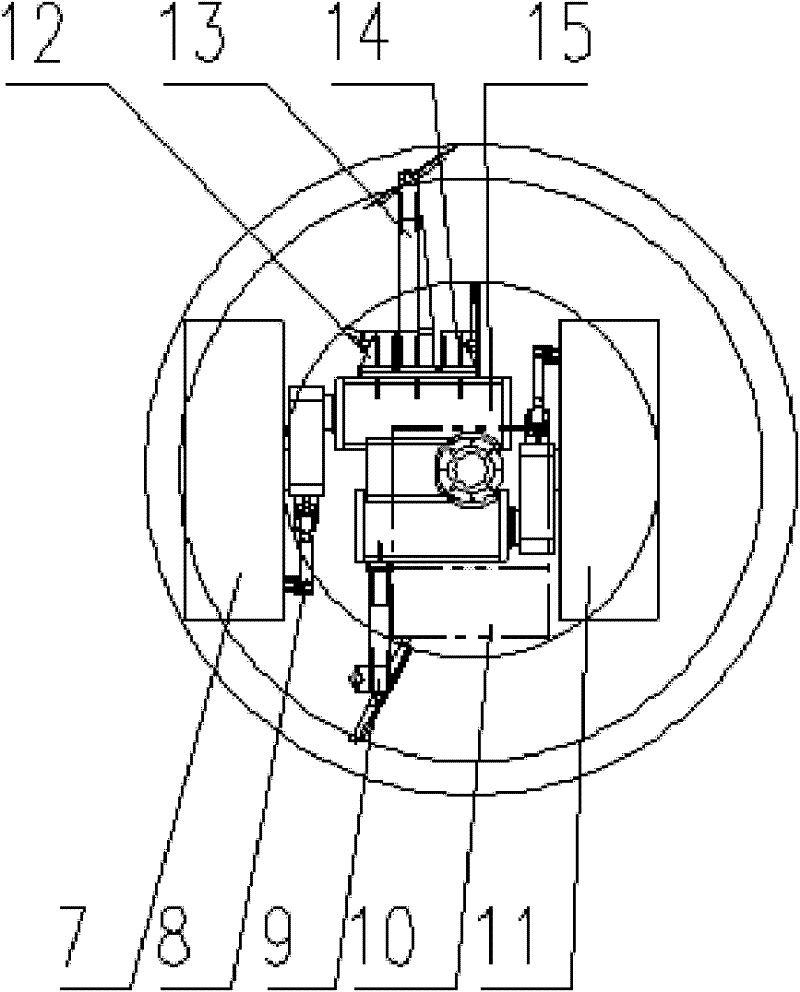

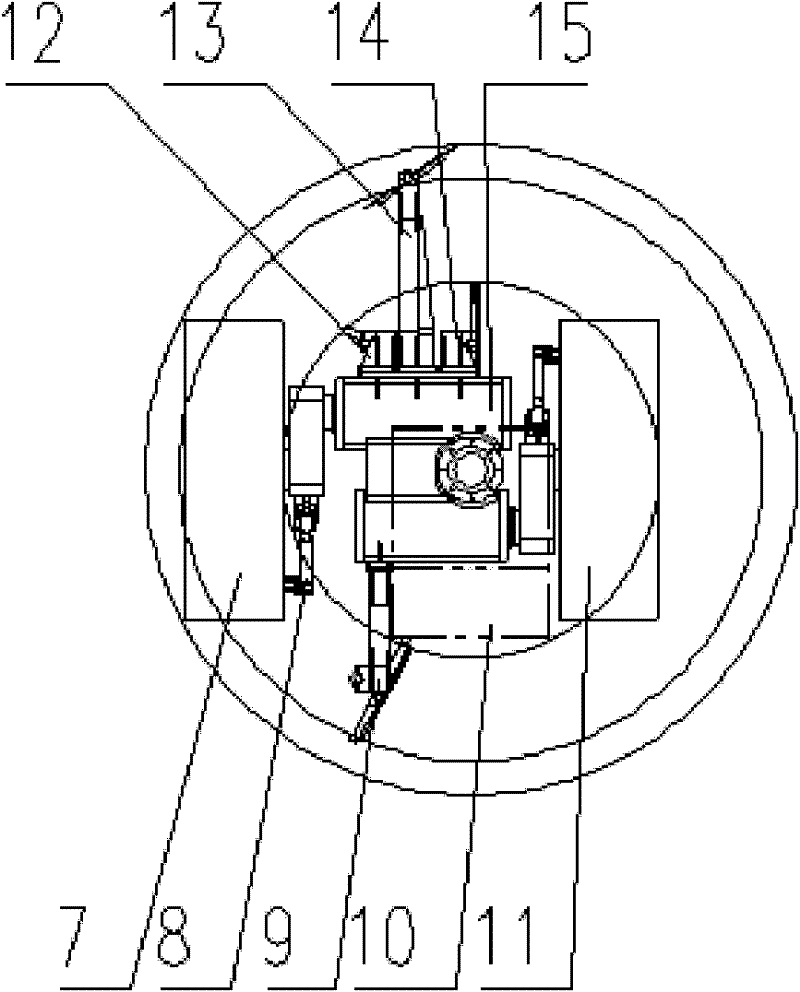

[0014] refer to figure 1 , figure 2 , and Fig. 3, a kind of wheel grinding machine, including power and transmission device, the main motor 1 of power and transmission device is connected to the main reducer 2 by belt transmission, and the output shaft of the final reducer 2 is connected to the The main rotary shaft of the rotary system 4 in the rolling device, the main rotary system 4 is installed and fixed on the rolling device composed of a welded grinding disc 6 and a frame 5, the main rotary system 4 is connected with the outer grinding wheel 7 and the outer grinding wheel 7 through the rotary support 15 The inner grinding wheel 11 is connected, and the roller surface scraper 8, the outer scraper 9, the feed hopper 10, the outer delivery scraper 13, the inner scraper 14 and the inner delivery scraper 12 are all fixed on the rotary support 15 and follow the of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com