Casting method and casting mold of vertical lathe ram

A casting mold and ram technology, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problem that forging blanks cannot make intermediate holes, etc., so as to shorten the production cycle, reduce energy consumption and pollution, and shorten the processing cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

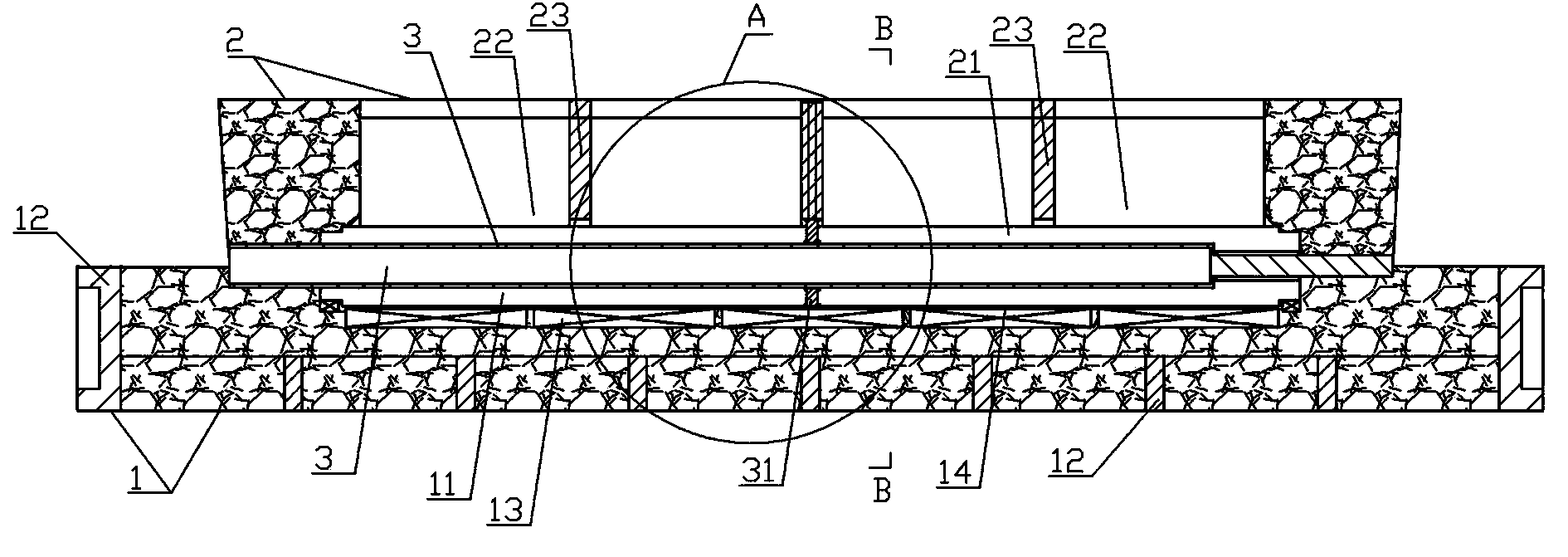

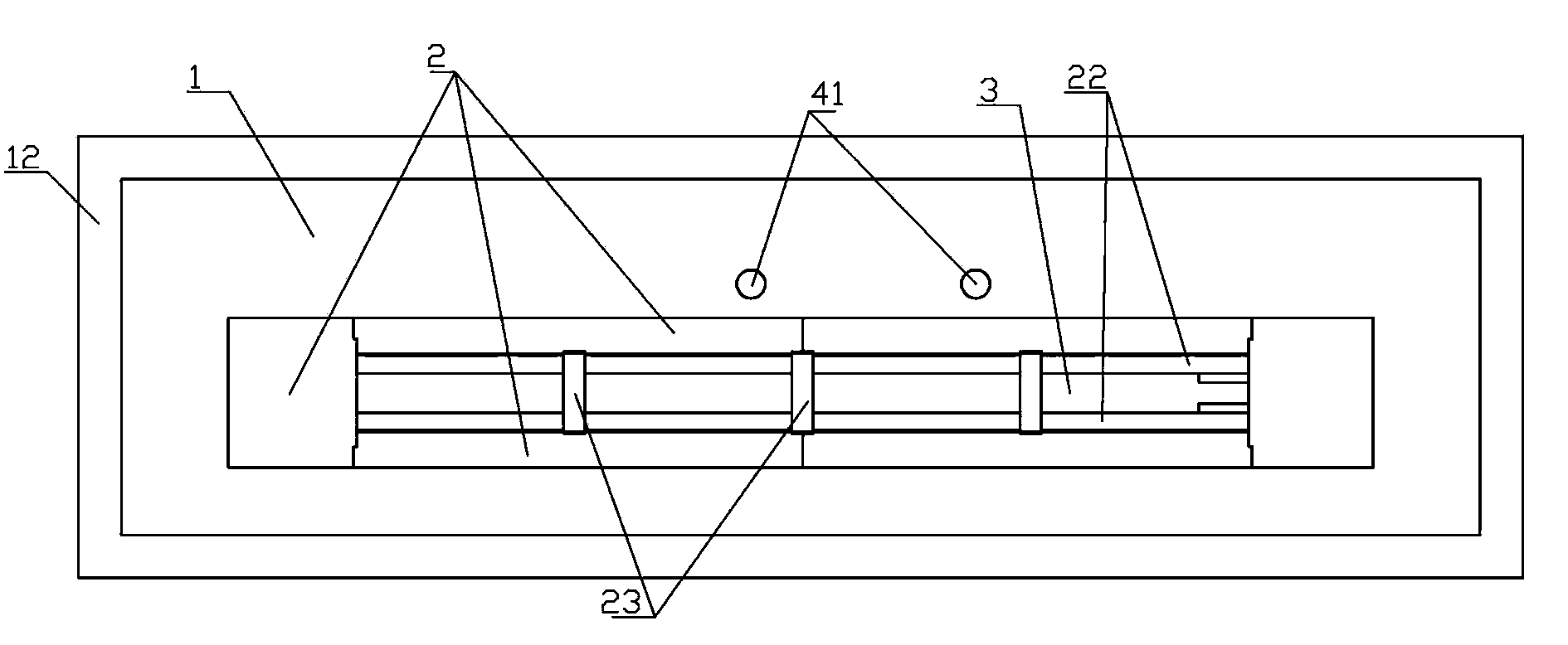

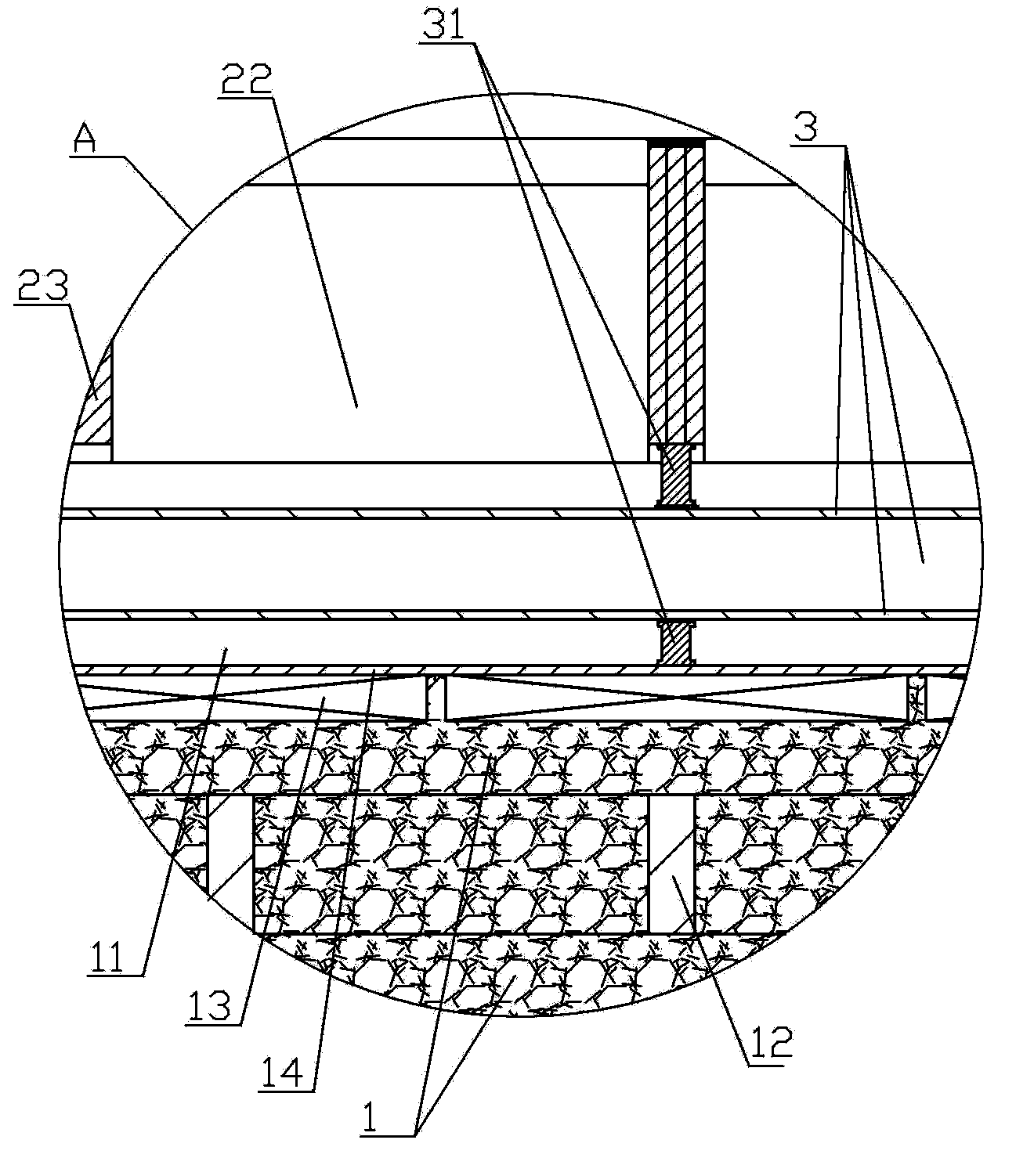

Embodiment 1

[0077] The material is ZG35CrMo, the size of the part is 350×350×4150, the weight of the casting is 3250kg, and the total pouring weight is 6600kg; when casting, the parting surface of the ram is divided into upper and lower parts, and each parting surface has a parting negative number. Sufficient processing allowance is left on the processing surface, and the casting shrinkage is 1.8%; the sprue 41, runner 42 and ingate 43 are wrapped with organic ester water glass quick-drying sand to prevent water from running out, and the sprue 41 is 2 channels of φ80, runner 42 is one of φ80, and ingate 43 is 4 channels of φ60 evenly distributed to ensure that the gating system is completely open; the metal cooling layer 13 is made of special material ZG270~500, and the sand layer 14 is made of resin sand. The sand thickness is 30~40mm, the distance between the metal blocks of the metal cooling layer 13 is not more than 30mm; the width of the bottom of the riser mouth is equal to the width...

Embodiment 2

[0079] The material is ZG35CrMo, the part size is 220×220×2710, the casting weight is 935kg, the total pouring weight is 1840kg, and the pouring temperature is 1560°C; when casting, the parting surface of the ram is divided into upper and lower parts, and each parting surface has a parting negative number. Sufficient processing allowance is left on the processing surface, and the casting shrinkage is 1.8%; the sprue 41, runner 42 and ingate 43 are wrapped with organic ester water glass quick-drying sand to prevent water from running out, and the sprue 41 is 2 channels of φ80, runner 42 is one of φ80, and ingate 43 is 4 channels of φ60 evenly distributed to ensure that the gating system is completely open; the metal cooling layer 13 is made of special material ZG270~500, and the sand layer 14 is made of resin sand. The sand thickness is 30~40mm, the distance between the metal blocks of the metal cooling layer 13 is no more than 30mm; the width of the bottom of the riser mouth is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com