Dust leakage preventing lapping structure of vibration groove

A technology of connecting structure and vibrating groove, applied in the direction of vibrating conveyor, conveyor, tobacco, etc., can solve the problems of increasing dust, long time for smoke and dust falling, increasing labor intensity of employees, etc., so as to reduce dust leakage and fugitive dust. , increase the thickness, avoid the effect of loose and poor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

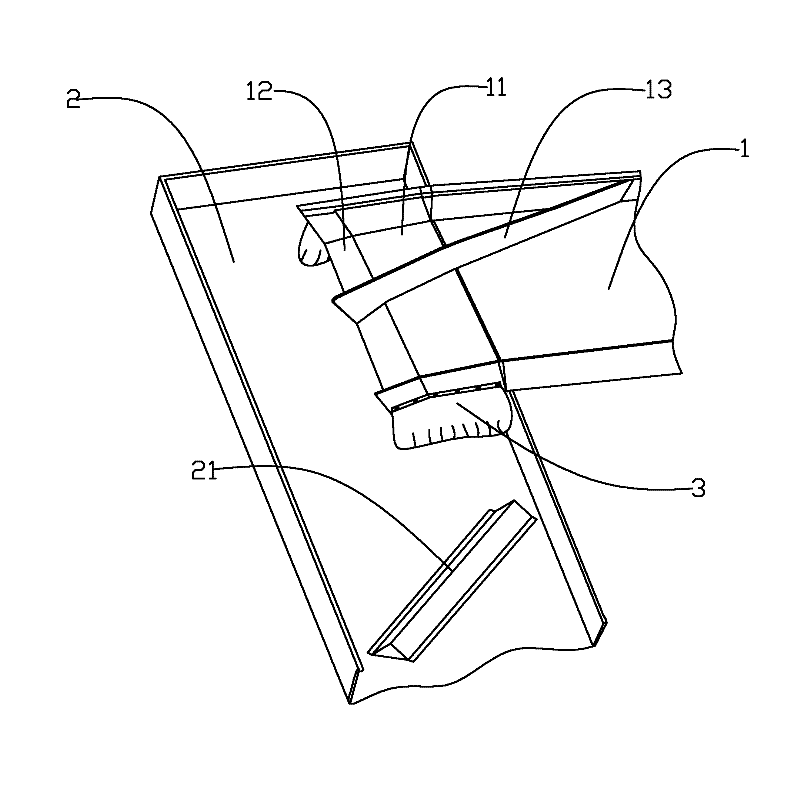

[0029] The following is a detailed description and explanation of the dust-proof vibration groove lapping structure described in the application of the present invention in conjunction with the accompanying drawings. Restriction of the scheme, in fact, within the spirit of the invention, the improvement of the overlapping structure of the vibration groove, the addition, deletion and replacement of the corresponding parts can all be obtained by those skilled in the art without creative work. Therefore all within the technical scheme that the application for protection of the present invention claims.

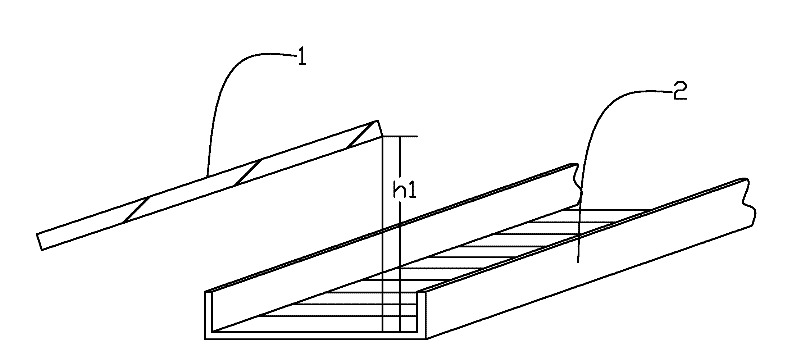

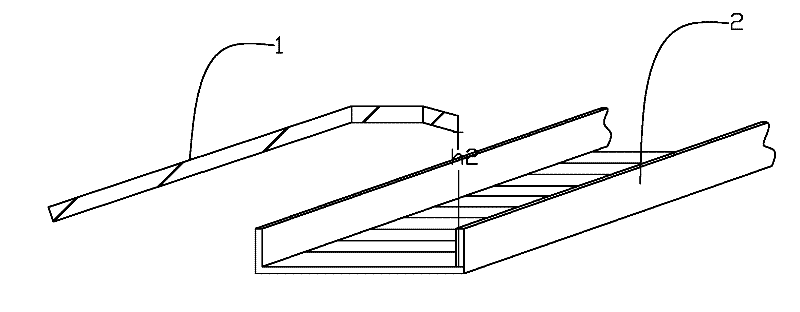

[0030] The original vibrating groove lap ends such as figure 1 As shown, it can be seen from the figure that the upper vibration groove 1 hangs obliquely above the lower vibration groove 2, and the vertical distance between the outlet end of the upper vibration groove 1 and the lower vibration groove 2 is h1; figure 2 It is a schematic diagram of the overlapping joint of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com