Bridge detection trolley

A technology of bridge detection and trolley, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as high labor cost, low operation efficiency, and potential safety hazards, and achieve the effects of eliminating potential safety hazards, reducing labor costs, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

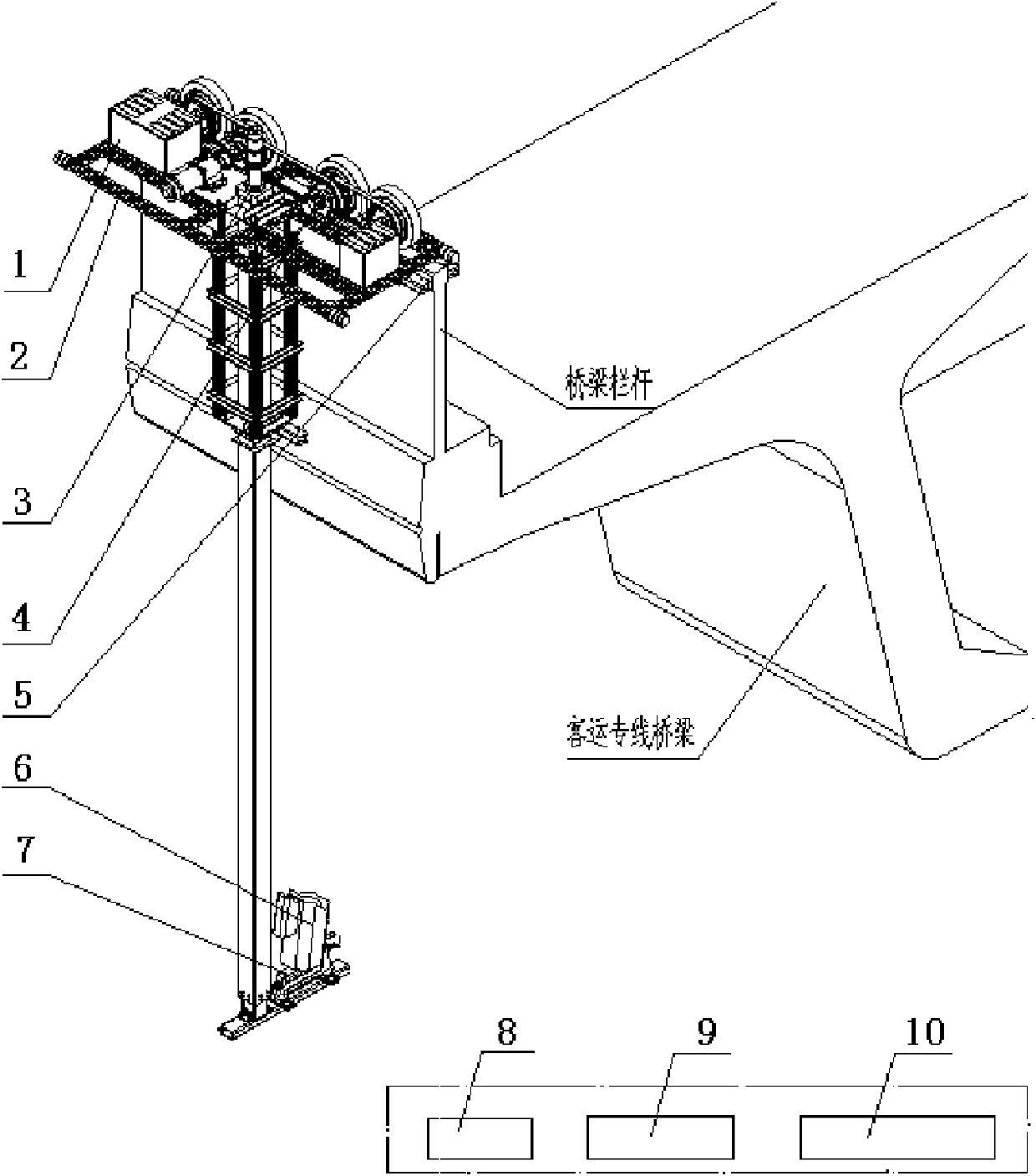

[0020] like figure 1 The shown bridge detection trolley is installed on the outside of the railing of the passenger dedicated line, and uses the railing of the passenger dedicated line as a running track, including an industrial computer 1, a frame 2, a lifting mechanism 3, an operating mechanism 4, a horizontal wheel 5, and a data acquisition device 6. Pitching mechanism 7, remote controller 8, local area network control station 9, monitoring center 10, running mechanism 4 is installed on the frame 2, horizontal wheels 5 are installed on the front and rear ends and the lower end of the bottom to guide, and the industrial computer 1 and the lifting mechanism 3 are fixedly installed on the frame 2 on.

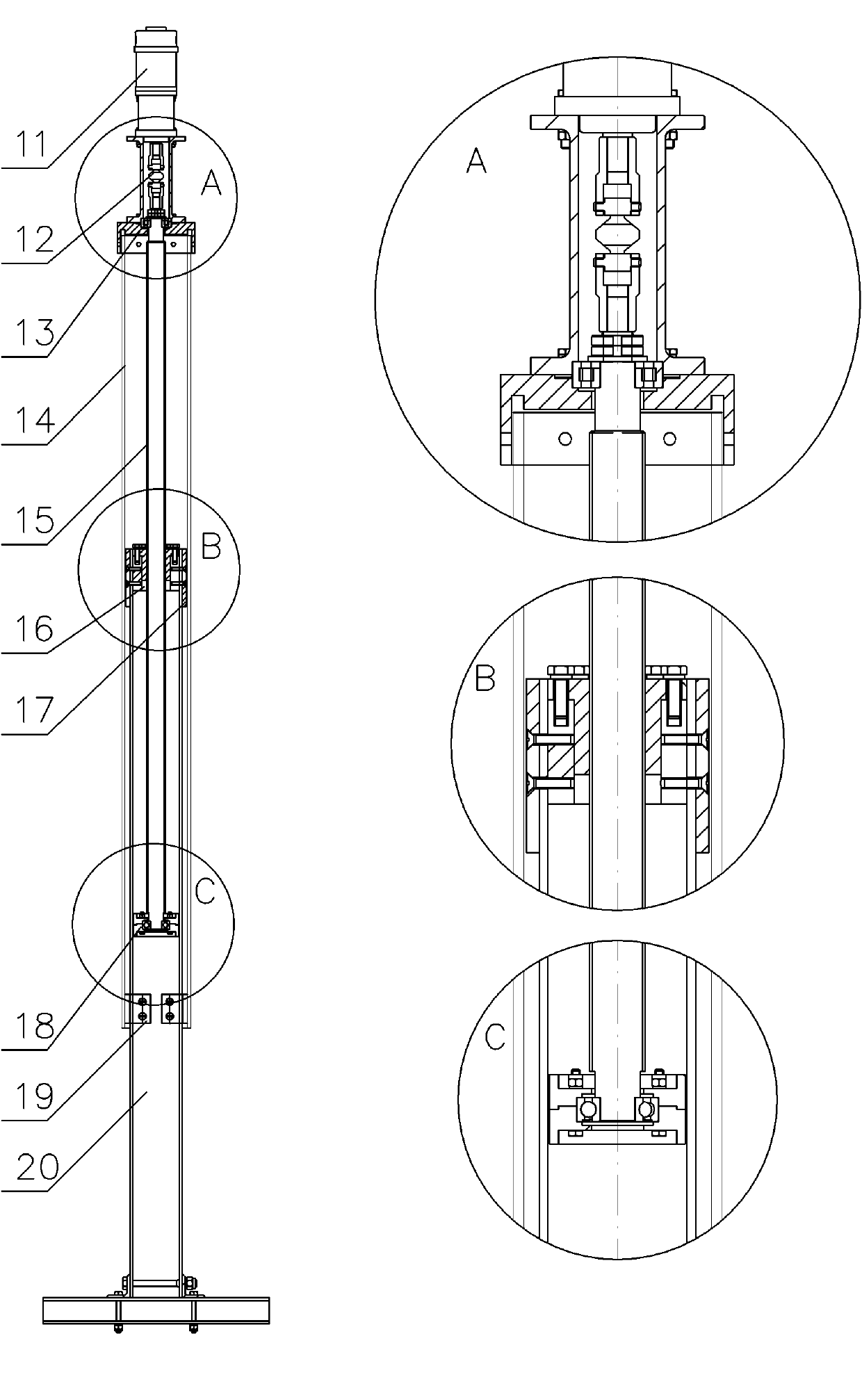

[0021] like figure 2 As shown, the lifting mechanism 3 is composed of a lifting mechanism power machine 11, a shaft coupling 12, a fixed support 13, a fixed guide cylinder 14, a screw 15, a nut 16, a slider 17, a floating support 18, a fixed slider 19, a lifting arm 20, etc. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com