Energy storage device and manufacturing method thereof

A technology of electric storage device and manufacturing method, which is applied in the direction of electrode manufacturing, secondary battery manufacturing, non-aqueous electrolyte storage battery electrodes, etc., and can solve problems such as circuit error operation and circuit damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

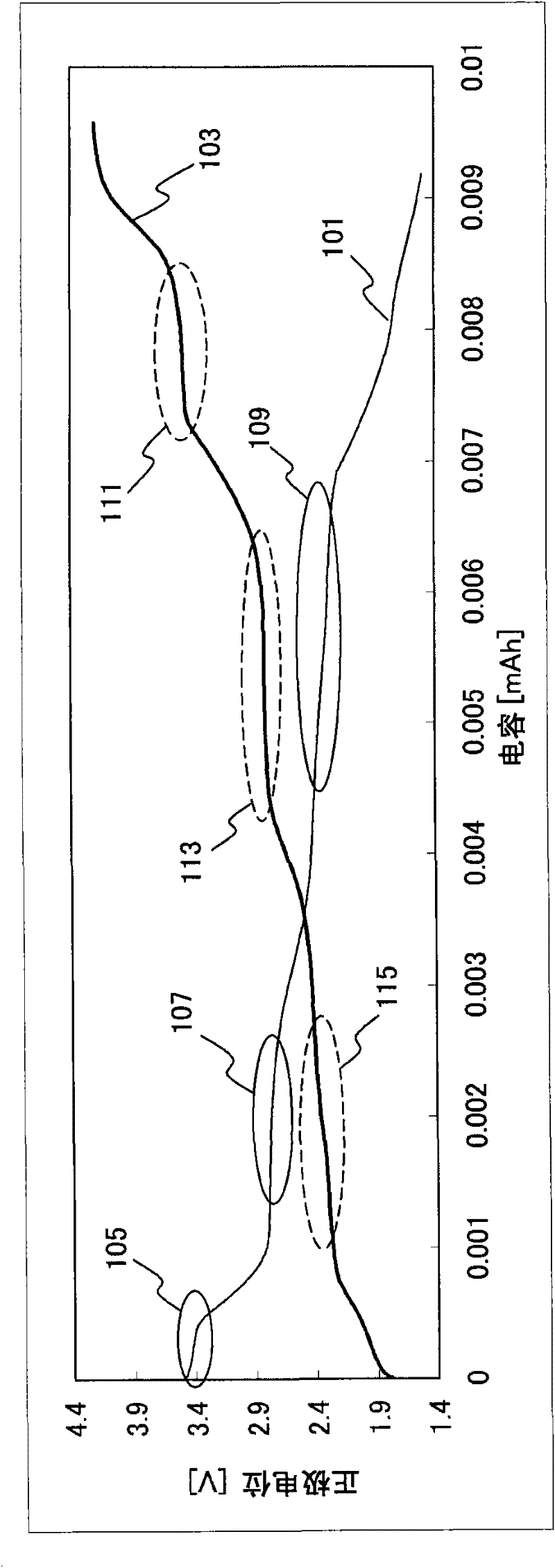

[0027] In this embodiment, the charge and discharge characteristics of the power storage device will be described.

[0028] figure 1 The charge and discharge characteristics of the positive electrode of the power storage device are shown, and a discharge curve 101 and a charge curve 103 are shown. The horizontal axis represents capacitance, and the vertical axis represents positive electrode potential.

[0029] exist figure 1 Among them, since the discharge curve 101 has a potential flat portion (hereinafter also referred to as a plateau), a stable voltage can be supplied. and, in figure 1 The example in has three stages of platforms (platform 105, platform 107, platform 109).

[0030] Furthermore, as the positive electrode potentials of each plateau in the discharge curve 101, the potential Vmax of the plateau 105=3.5V, the potential Vmid of the plateau 107=2.9V, and the potential Vmin of the plateau 109=2.4V.

[0031] Since the discharge curve 101 has three stages of pl...

Embodiment approach 2

[0045] In this embodiment, an example of a method of manufacturing an electrical storage device capable of realizing the charge-discharge characteristics described in Embodiment 1 will be described.

[0046] Figure 2A to Figure 2C It is an example of the manufacturing method of the positive electrode of a lithium secondary battery.

[0047] First, the current collector 201 ( Figure 2A ).

[0048] The material of current collector 201 is not particularly limited, and highly conductive materials such as platinum, aluminum, copper, and titanium can be used. Titanium is used in this embodiment.

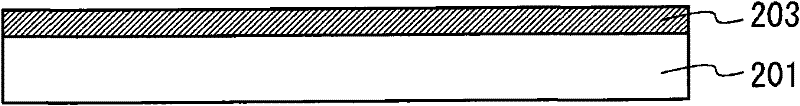

[0049] Next, a film 203 containing an active material is formed on the current collector 201 ( Figure 2B ).

[0050] As the active material contained in the active material-containing film 203, lithium oxide is preferably used. Since lithium has a large ionization tendency and a small atomic radius, it can be stably inserted into and detached from the positive electrode. Thereby...

Embodiment approach 3

[0061] In this embodiment, an example of the configuration of the power storage device will be described.

[0062] use Figure 2C An example of the structure of the positive electrode used in the power storage device will be described.

[0063] The positive electrode 205 includes a current collector 201 and an active material-containing film 203 formed on the current collector 201 .

[0064] As the material of current collector 201 , the materials described in Embodiment Mode 2 can be used. Titanium is used in this embodiment.

[0065] As the material of the active material, the materials described in Embodiment Mode 2 can be used. In this embodiment, lithium iron phosphate with a thickness of 100 nm is used.

[0066] Next, an example of the structure of a power storage device using the above-mentioned positive electrode will be described.

[0067] Figure 3A to Figure 3C This is an example of the structure of an electrical storage device including a positive electrode 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com