Drive device, display panel module, display device and method for manufacturing drive device

A driving device and display device technology, applied in the direction of static indicators, optics, instruments, etc., can solve the problems of excessive wiring, increase the use of carrier tape, and can not achieve cost reduction, etc., to achieve the effect of low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

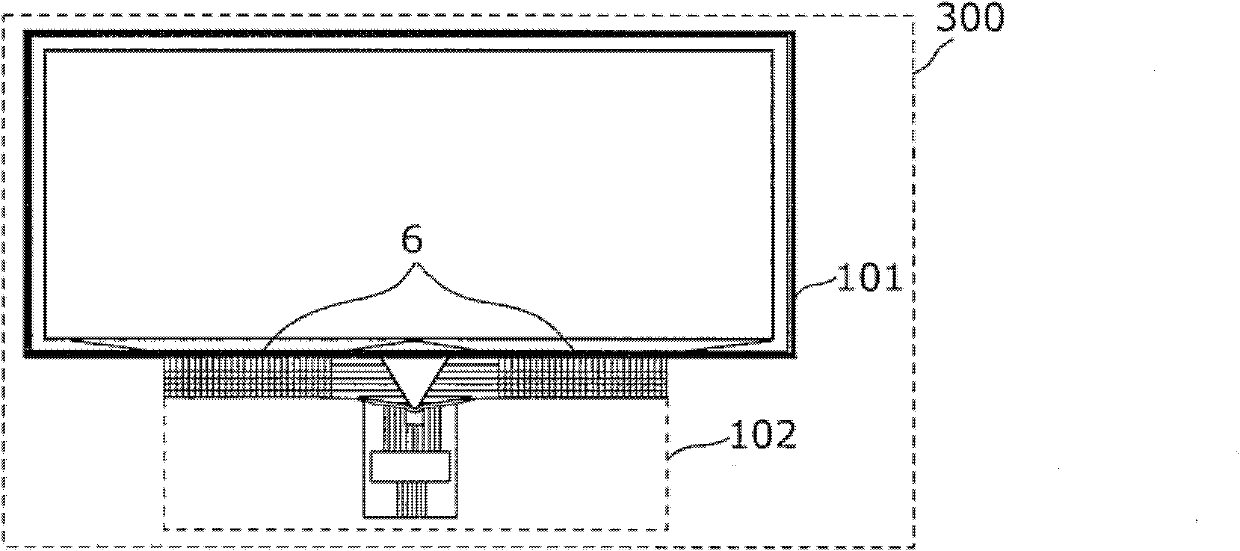

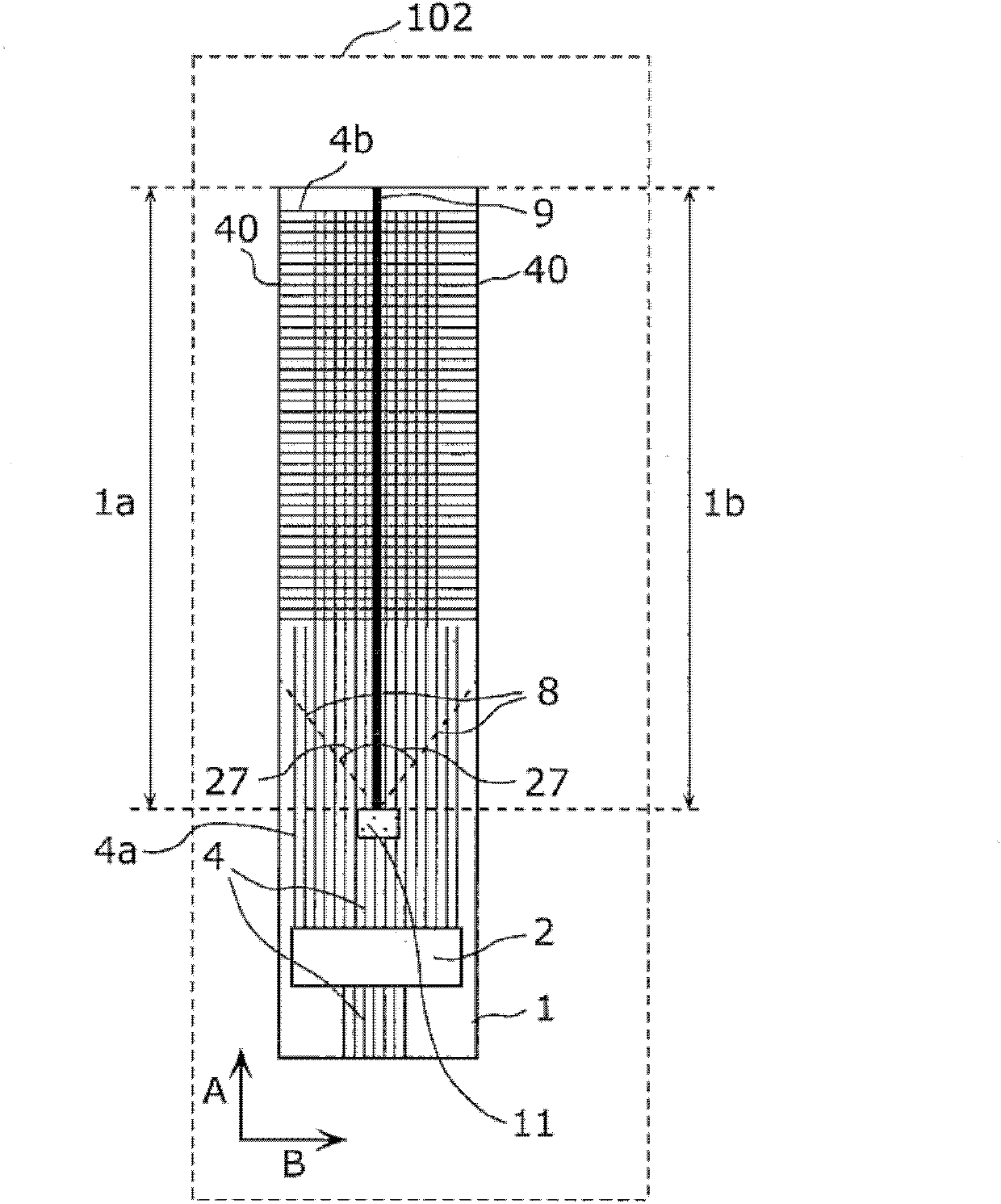

[0115] Figure 1A is a plan view showing the configuration of the display screen module 300 in this embodiment. Figure 1B It is a plan view showing the shape of the driving device 102 in this embodiment before being attached to the liquid crystal panel 101 . exist Figure 1A Among them, the display module 300 is composed of a liquid crystal screen 101 and a driving device 102 , the driving device 102 is connected to the wiring 6 on the substrate included in the liquid crystal screen 101 and drives the liquid crystal screen 101 . The driving device 102 is mounted on the outer edge of the liquid crystal panel 101, and includes the film 1 on which the wiring 4 and the circuit element 2 are mounted.

[0116] In addition, although the display panel is described as a liquid crystal panel here, the same effect can be obtained also in a thin display such as an organic electroluminescent panel or a plasma display.

[0117] Such as Figure 1B It is shown that the driving device 102...

Deformed example 1

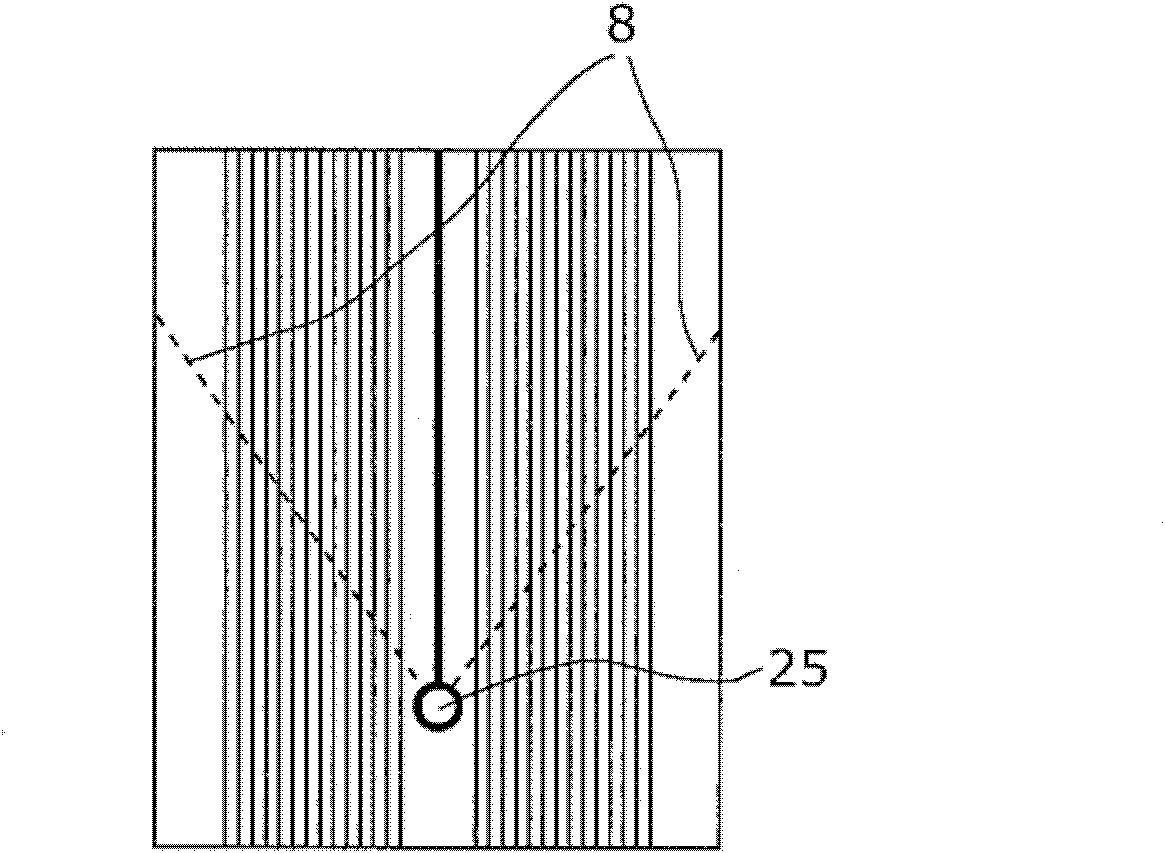

[0137] use Figure 5A to Figure 6C Modifications related to measures against disconnection of the wiring 4 on the thin film 1 in the driving device 102 of the present embodiment will be described.

[0138] Figure 5A is a plan view showing the shape of the driving device 102 before being mounted on the liquid crystal panel 101, Figure 5B The diagram around the bending position 8 of the driving device 102 is shown enlarged.

[0139] Such as Figure 5B As mentioned above, by setting the wiring strengthening part 20 that changes the width of the wiring 4 at the intersection of the wiring 4 and the bending position 8 on the film 1, specifically, by making the line width of the wiring 4 at the bending position 8 of the film 1 By widening, the effect of reducing the disconnection failure rate of the wiring 4 in the drive device 102 can be obtained.

[0140] Figure 6A is a plan view showing the shape of the driving device 102 before being mounted on the liquid crystal panel 10...

Embodiment 2

[0145] Figure 7A is a plan view showing the configuration of the display screen module 301 in this embodiment. Figure 7B It is a plan view showing the shape of the driving device 103 in this embodiment before being attached to the liquid crystal panel 101 .

[0146] exist Figure 7A Among them, the display module 301 is composed of a liquid crystal screen 101 and a driving device 103 . The driving device 103 is connected to the wiring 6 on the substrate included in the liquid crystal screen 101 and drives the liquid crystal screen 101 . The driving device 103 is mounted on the outer edge of the liquid crystal panel 101, and includes the film 1 on which the wiring 4 and the circuit element 2 are mounted. Moreover, the display screen module 301 of this embodiment also constitutes as Figure 4A to Figure 4C display device.

[0147] Such as Figure 7B It is shown that the driving device 103 utilizes the film 1 as a base material, mounts the circuit element 2 on the film 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com