Hermetically sealed battery and method for manufacturing the same

A manufacturing method and airtight technology, applied in the field of joint structure, can solve the problems of severe electrode loss and difficult long-term stable welding, and achieve the effect of suppressing and reducing the occurrence of spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

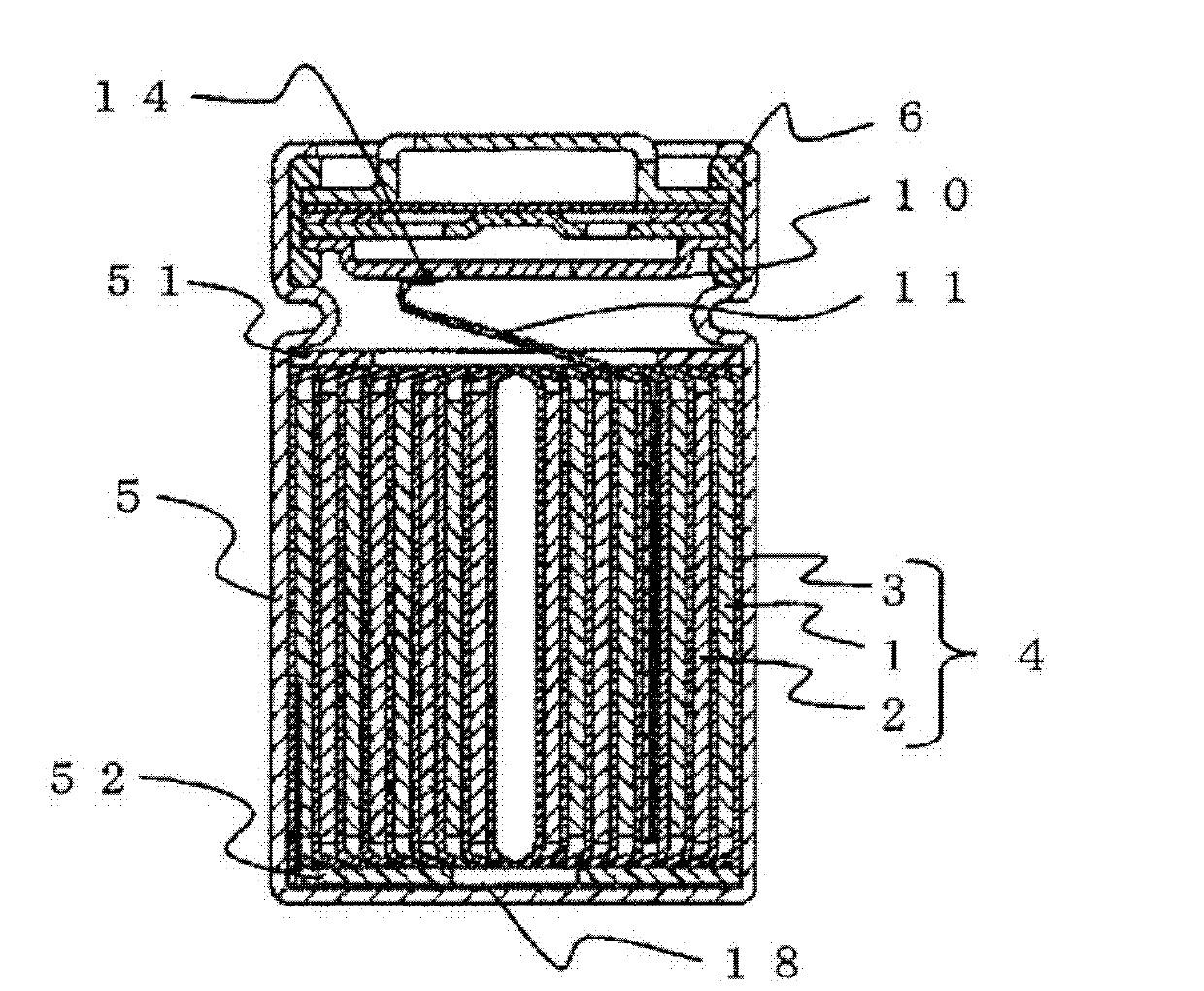

Embodiment 1

[0075] The positive electrode plate 1 was produced by the following method. First, use a kneader to mix 100 parts by weight of lithium cobaltate as an active material, 2 parts by weight of acetylene black as a conductive material, 2 parts by weight of polyvinylidene fluoride (PVdF) as a binder material, and an appropriate amount of N-methyl 2-Pyrrolidone is stirred together to produce a positive electrode mixture coating. Next, the positive electrode mixture paint was coated on both sides of a positive electrode current collector made of aluminum foil with a thickness of 15 μm, dried, pressed to make the total thickness 165 μm, and then longitudinally sheared to produce the positive electrode plate 1. .

[0076] In addition, the negative electrode plate 2 was produced by the following method. First, 100 parts by weight of artificial graphite as an active material, 2.5 parts by weight of a styrene-butadiene copolymer rubber particle dispersion (solid content of 40% by weight)...

Embodiment 2

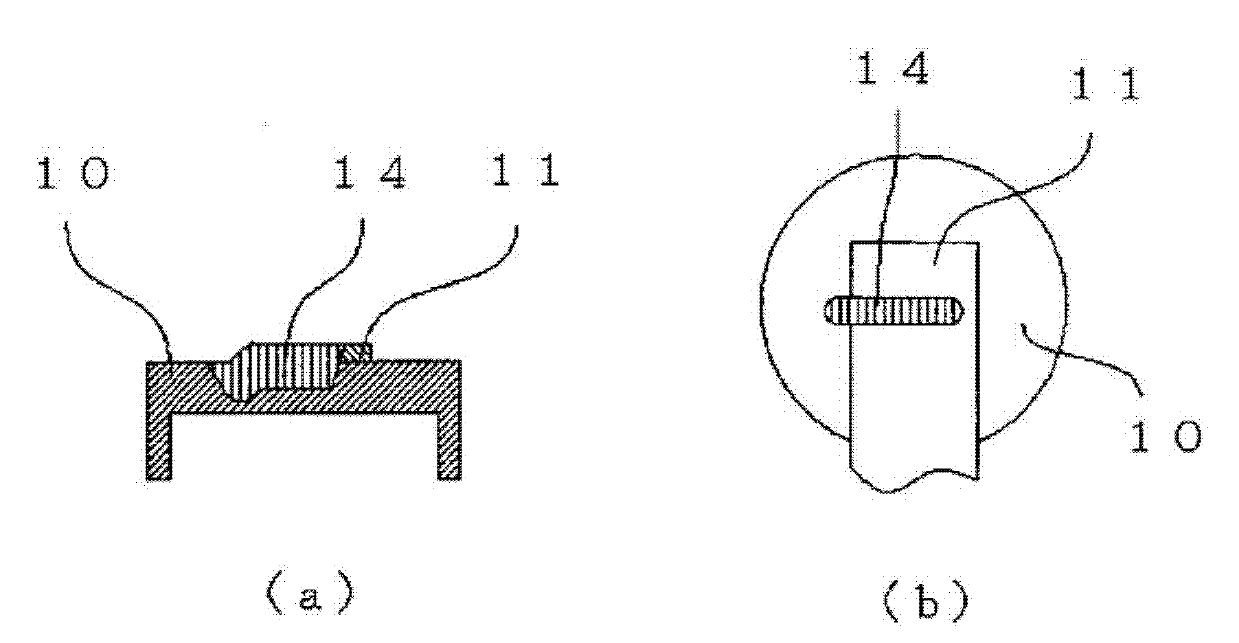

[0084] Using the electrode group 4 produced in the same manner as in Example 1, the width of the lead wire 11 is 2mm, and the welding part 14 is as Figure 4 As shown in (b), except that the surface of the lead wire 11 and the surface of the sealing plate 10 on the outside of both ends were laser welded in the same manner as in Example 1, a lithium ion secondary battery was produced, and the lithium ion secondary battery was fabricated. As Example 2.

Embodiment 3

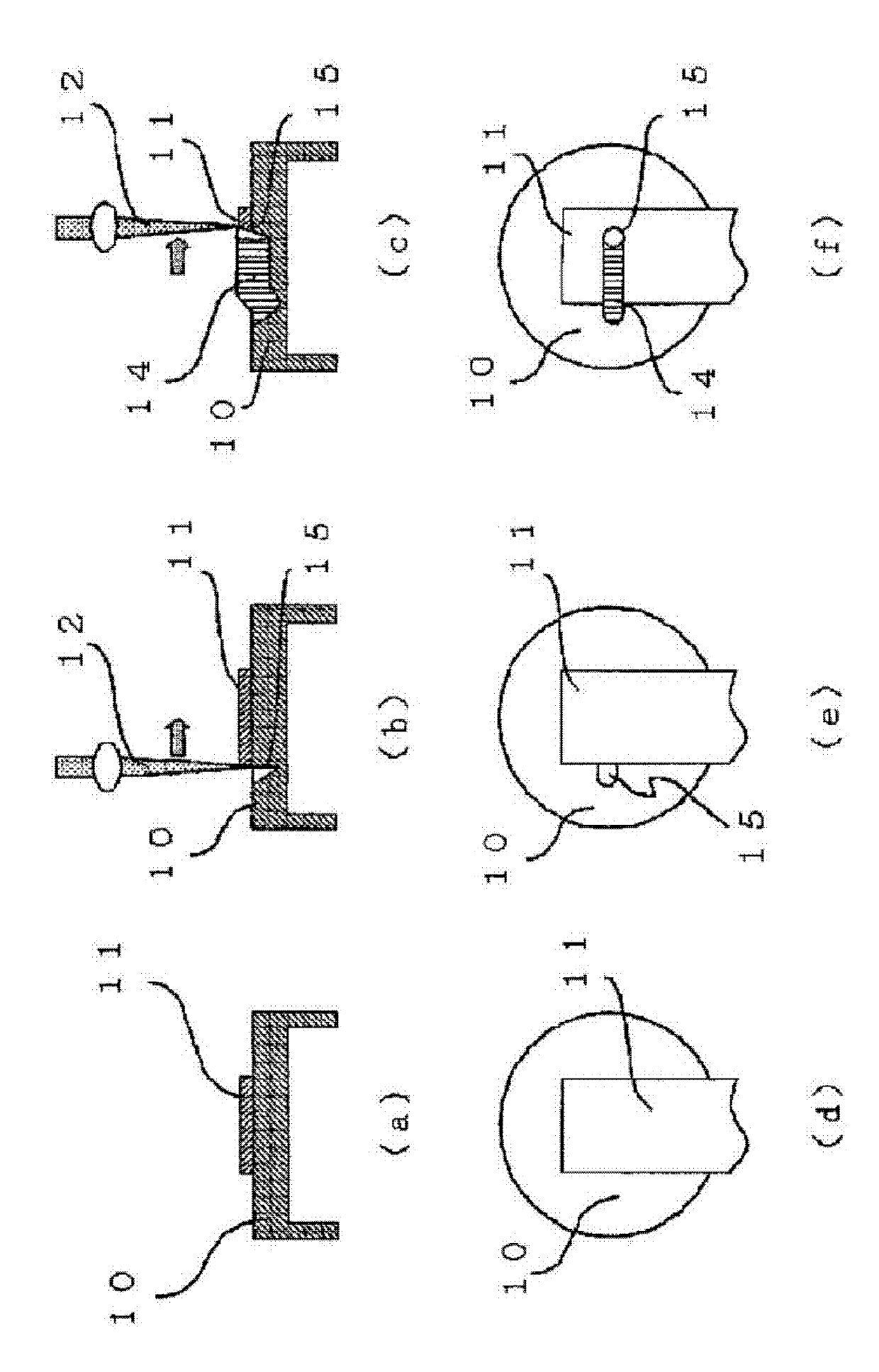

[0090] Using the electrode group 4 produced in the same manner as in Example 1, except that the fusion width of the welded portion 14 was set to 0.4 mm, and the fusion length was set to 1.6 mm, laser welding was performed in the same manner as in Example 1, thereby A lithium-ion secondary battery was produced.

[0091] As a result, a stable weld strength of about 15N was obtained. Therefore, it is preferable to set the ratio of the welding length to the welding width of the linear welding portion 14 to be 4 or more.

[0092] The joint strength is related to the welded area which is the product of the length of the welded part 14 and the welded width. If the weld width is made constant, it is related to the weld length. The welding width depends on the melting area when the laser beam 12 is irradiated, but the welding width is basically smaller because the smaller the melting area can suppress the generation of spatter. However, if the welding width is too small, it will be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com