Combined hydraulic pre-tightening locking device and hard alloy compound roller

A locking device and a combined technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of harsh material requirements, unfavorable multiple use, high price, etc., and achieve long service life, not easy to age, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

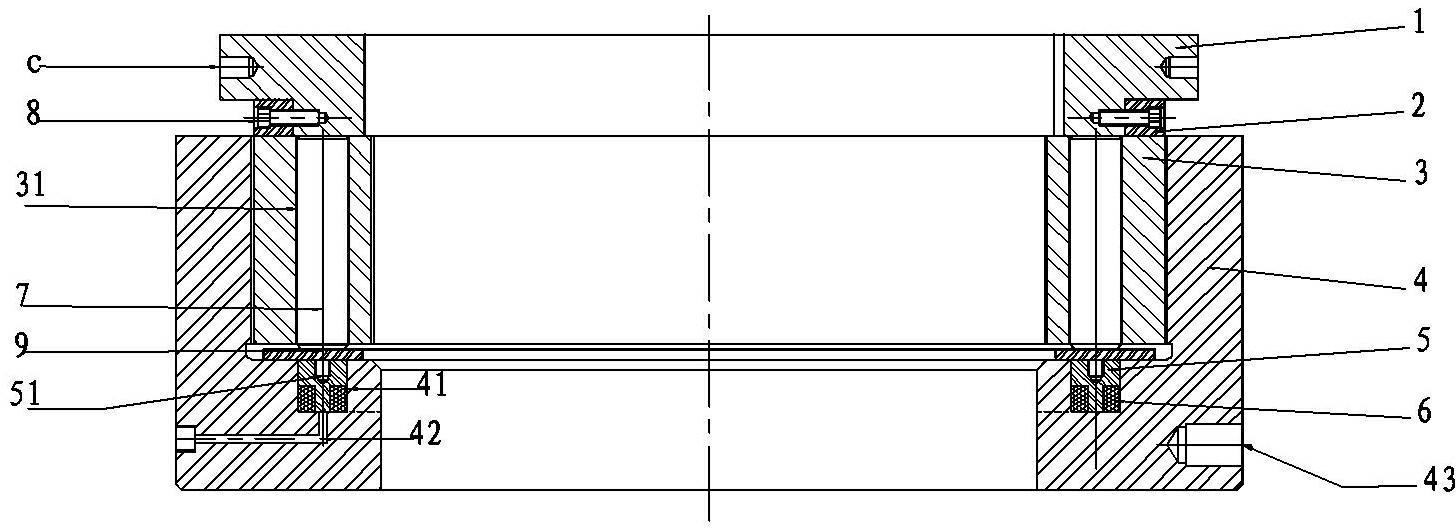

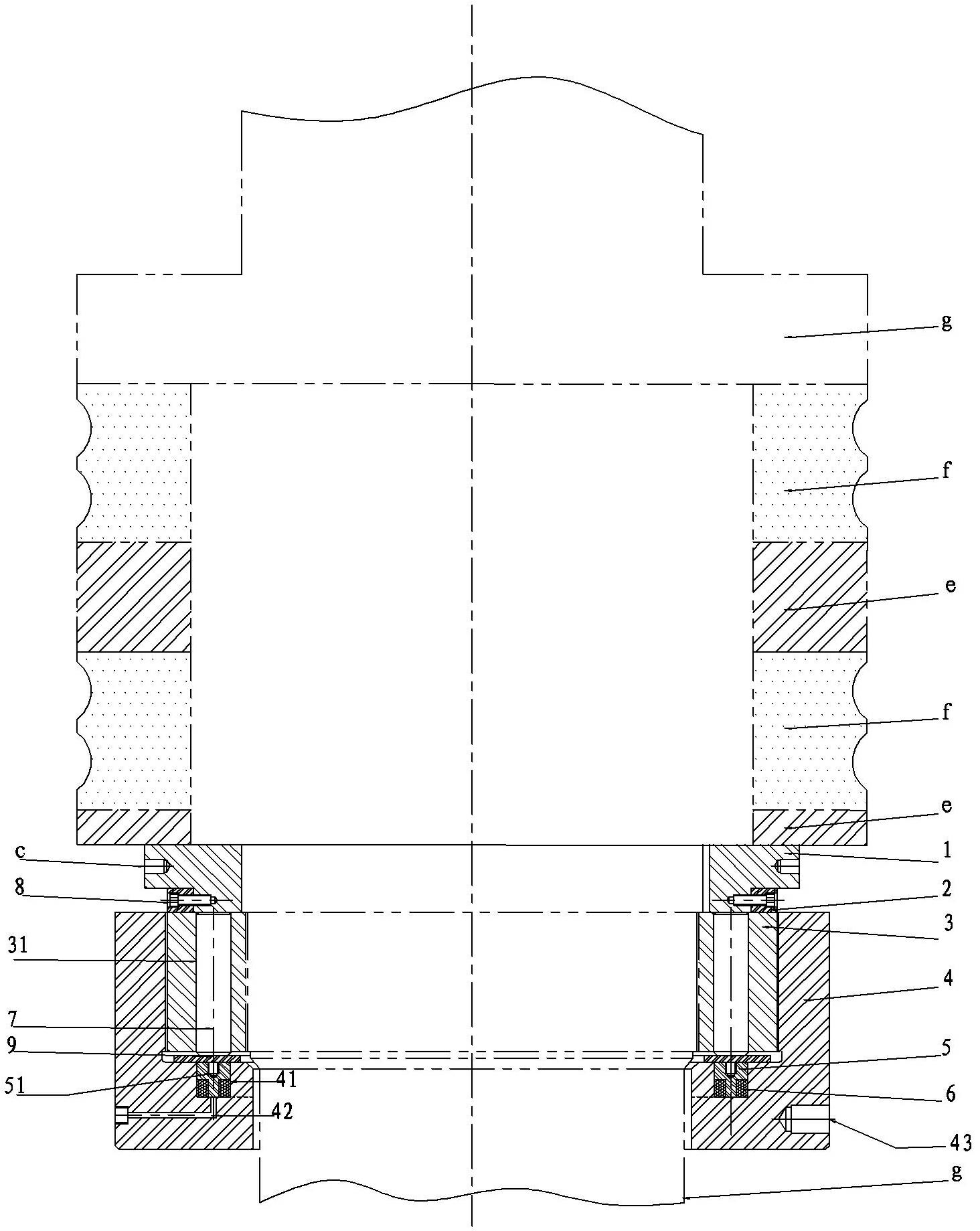

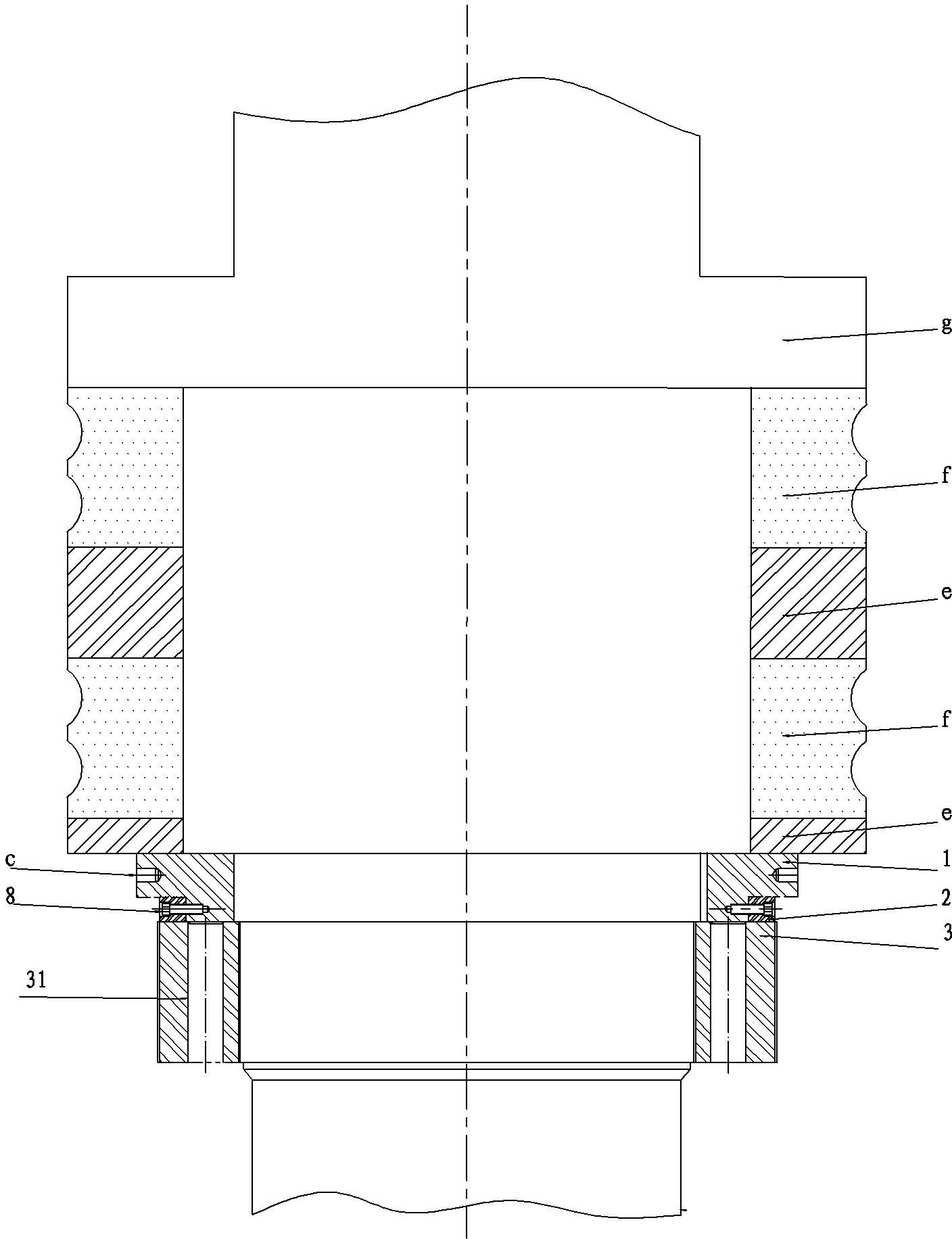

[0016] Such as figure 1 As shown, a combined hydraulic pre-tightening locking device includes a pre-tightening nut 3, a T-shaped backing ring 1 with a "T"-shaped shaft section, a pair of semi-circular half-rings 2, and a number of transmissions. Force column 7, hydraulic flange 4, annular backing ring 9, annular piston 5 and sealing ring 6; external thread and some uniformly distributed axial through holes 31 are also designed on the pre-tightening nut 3, and the force transmission column 7 is connected with the pre-tightening A number of axial through holes 31 of the nut 3 are matched and can move axially therein, the length of which is greater than the length of the axial through holes 31, and the lower end surface is connected with the annular backing ring 9 placed between the pre-tightening nut 3 and the hydraulic flange 4 The upper end is in contact with each other; the diameter of the small end of the T-shaped backing ring 1 is larger than the diameter of the outer edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com