Acupuncture needle machining and packaging device and method

A technology of acupuncture needles and processing department, which is applied in the field of processing molding and automatic packaging devices, which can solve the problems of wasted man-hours, unstable yield rate, and inability to reduce manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

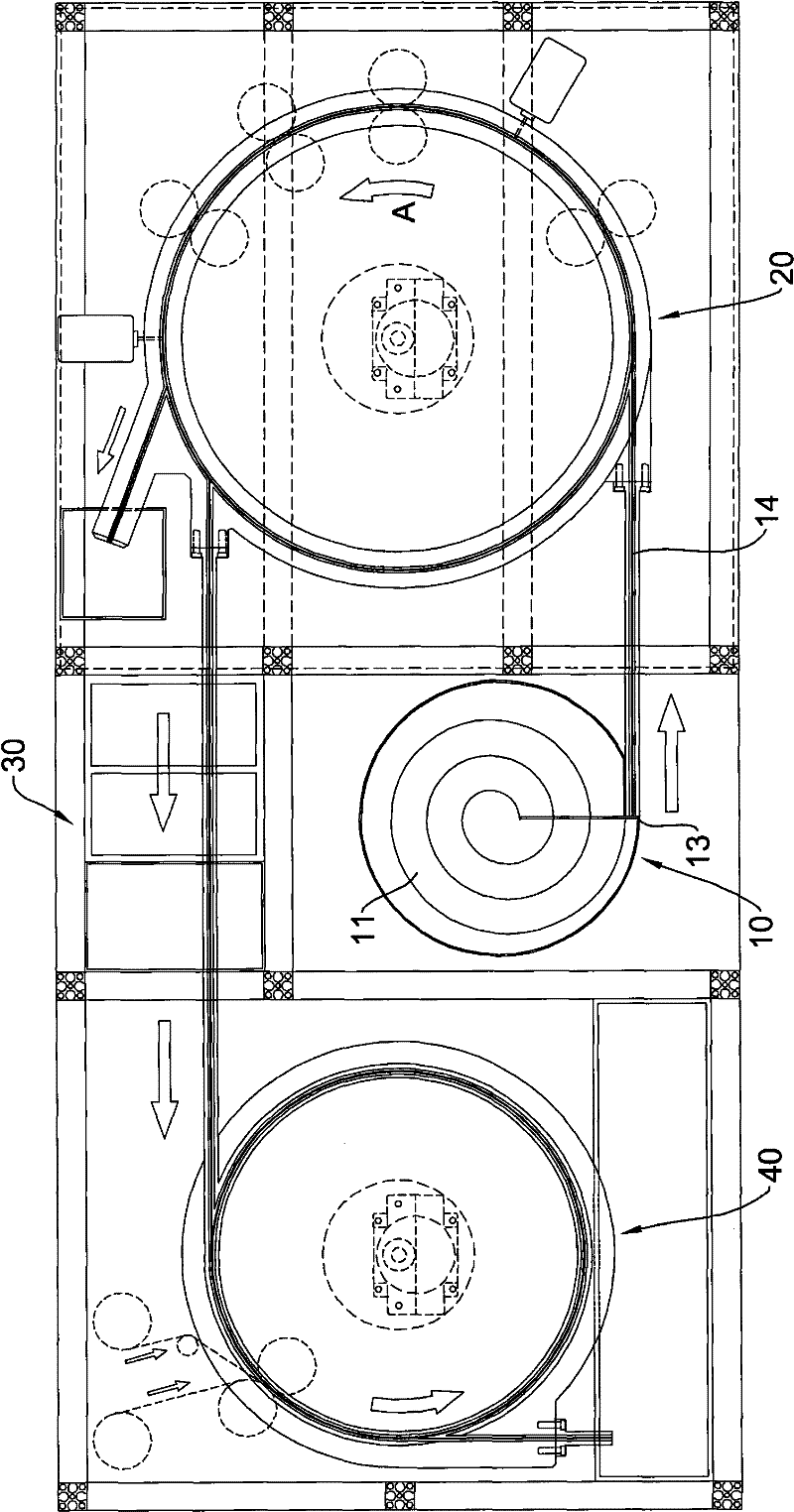

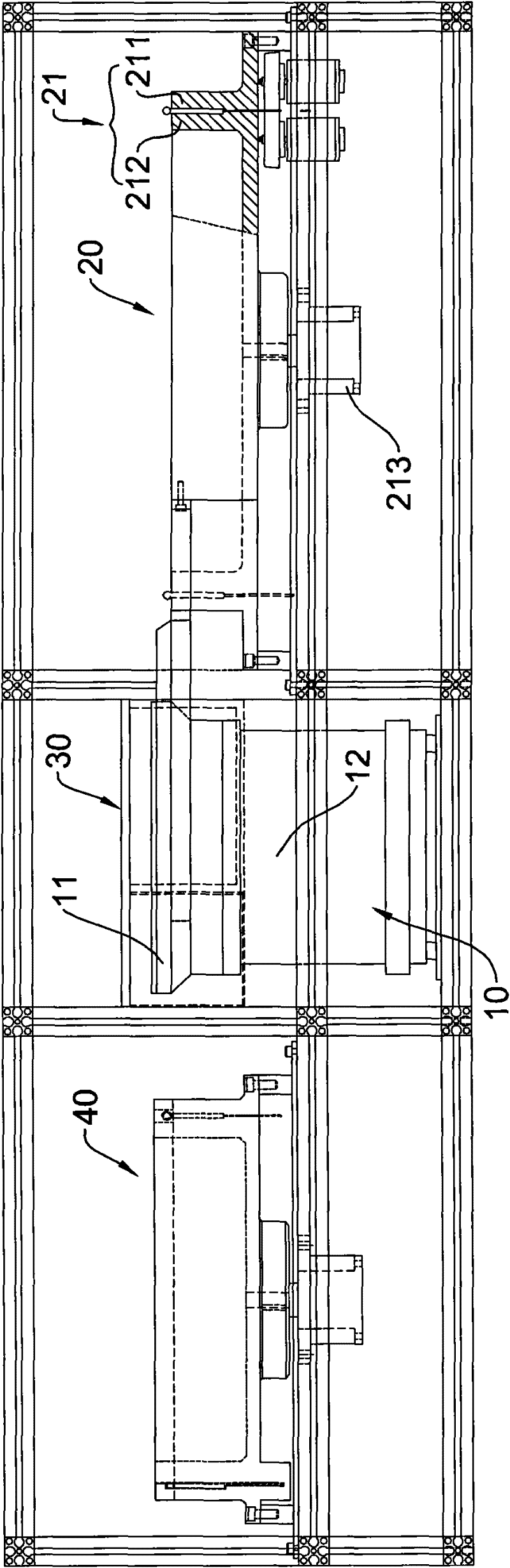

[0051] Such as figure 1 and figure 2 As shown, the acupuncture needle processing and packaging device of the present application includes a machine platform on which an automatic feeding part 10, a needle body processing part 20, a disinfection treatment part 30, an automatic packaging part 40 and a servo controller.

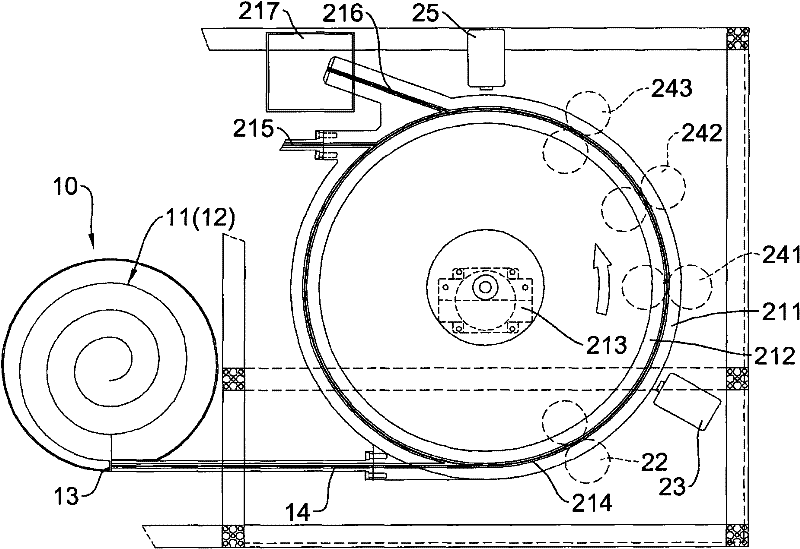

[0052] The automatic feeding part 10 has a feeding tray 11, a vibration module 12 and a feeding track 14, wherein the feeding tray 11 has a feeding port 13, and the two ends of the feeding track 14 are connected to the feeding port 13 respectively. connected, and the vibrating module 12 provides an oscillating force to act on the feeding tray 11, so that the material (for example: acupuncture needle embryos) placed therein tends to move in the direction of the feeding port 13 through the vibration of the feeding tray 11 trend, and then enter the feed track 14.

[0053] Such as figure 2 and image 3As shown, the needle shaft processing part 20 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com