Nano-silica surface-grafted with antioxidant molecule and preparation method and application thereof

A nano-silica, surface grafting technology, applied in the treatment of dyed low molecular organic compounds, fibrous fillers, etc., can solve the problems of poor extraction resistance, easy loss, easy migration, etc. The effect of improving the anti-photooxidative aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

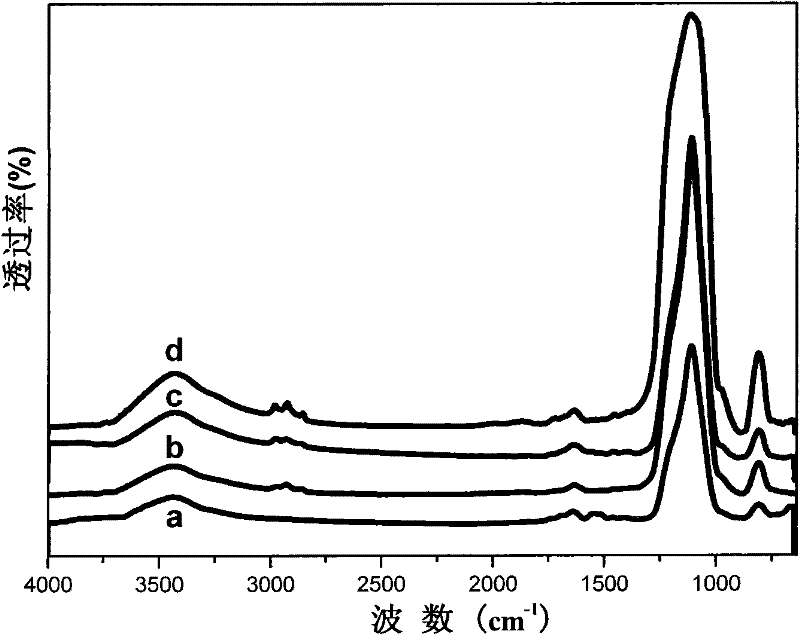

[0036] The nano-silica used is Degussa A-200, prepared by gas phase method, the primary particle size is 12nm, and the specific surface area is 200±25m 2 / g (eg figure 1 a). The surface contains hydroxyl groups and unsaturated residual bonds, and has strong hydrophilicity.

[0037] Antioxidant-modified nano-silica: Weigh 30 g of antioxidant methyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, stir and melt at a temperature of 65°C to 75°C, Then add the above-mentioned 1g of nano-silica and 0.045g of sodium methoxide, stir to form a nano-silica dispersion suspension; under the protection of nitrogen, the suspension is stirred and reacted at 110°C for 3 hours, then filtered, and the filter cake obtained after filtration Wash three times with ethanol and methanol respectively, and the amount of solvent used for each washing is 200ml. Put the washed modified nano silicon dioxide into a vacuum oven, and dry it at 105° C. for 6 hours. The nano silicon dioxide with antioxida...

Embodiment 2

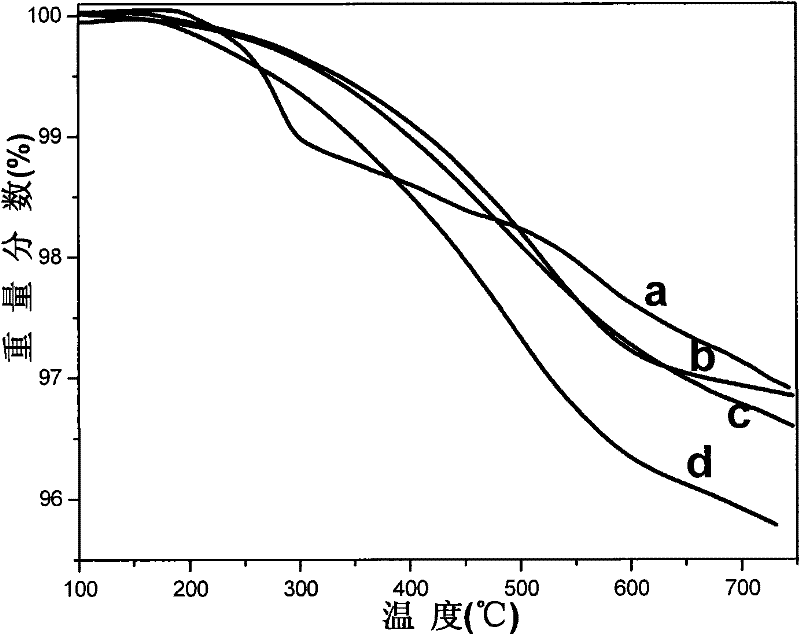

[0040] Weigh 30 g of antioxidant 3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate methyl ester, stir and melt at a temperature of 65 ° C to 75 ° C, and then add 1 g of nanometer di Silicon oxide and 0.055g of sodium methoxide are stirred to form a nano-silica dispersion suspension; the suspension is stirred and reacted at 110°C for 3 hours under the protection of nitrogen, and then filtered, and the filter cake obtained after filtration is washed with ethanol and acetone respectively For three times, the amount of solvent used for each washing is 200ml. Put the washed modified nano silicon dioxide into a vacuum oven, and dry it at 100° C. for 7 hours. The nano silicon dioxide with antioxidant molecules grafted on the surface is obtained. from figure 2 According to the thermogravimetric curve of c, the amount of grafted antioxidant on the surface of nano-silica accounts for 3.2% of the weight of nano-silica grafted with antioxidant molecules on the surface.

Embodiment 3

[0042] Weigh 30 g of antioxidant 3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate methyl ester, stir and melt at a temperature of 65 ° C to 75 ° C, and then add 1 g of nanometer di Silicon oxide and 0.065g of sodium methoxide were stirred to form a nano-silica dispersion suspension; the suspension was stirred and reacted at 110°C for 3 hours under the protection of nitrogen, and then filtered, and the filter cake obtained after filtration was washed with ethanol and N, N -Dimethylformamide was washed three times each, and the amount of solvent used for each washing was 200ml. Put the washed modified nano silicon dioxide into a vacuum oven, and dry it for 5 hours at a temperature of 110°C. The nano silicon dioxide with antioxidant molecules grafted on the surface is obtained. from figure 2 The thermogravimetric curve of d shows that the grafting amount of antioxidant on the surface of nano-silica accounts for 4.8% of the weight of nano-silica grafted with antioxidant molecul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com