Technological process for floating oil delivering and settling dehydration of crude oil

A technology of process flow and crude oil, applied in the direction of mechanical dehydration/emulsification, etc., can solve the problems of not being able to adjust the settling time according to the process requirements, increase the intermediate residence time and intermediate costs, change and adjust the oil outlet position, etc., to reduce production Effects of operating costs and management costs, reducing infrastructure costs, and reducing the amount of water carried

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

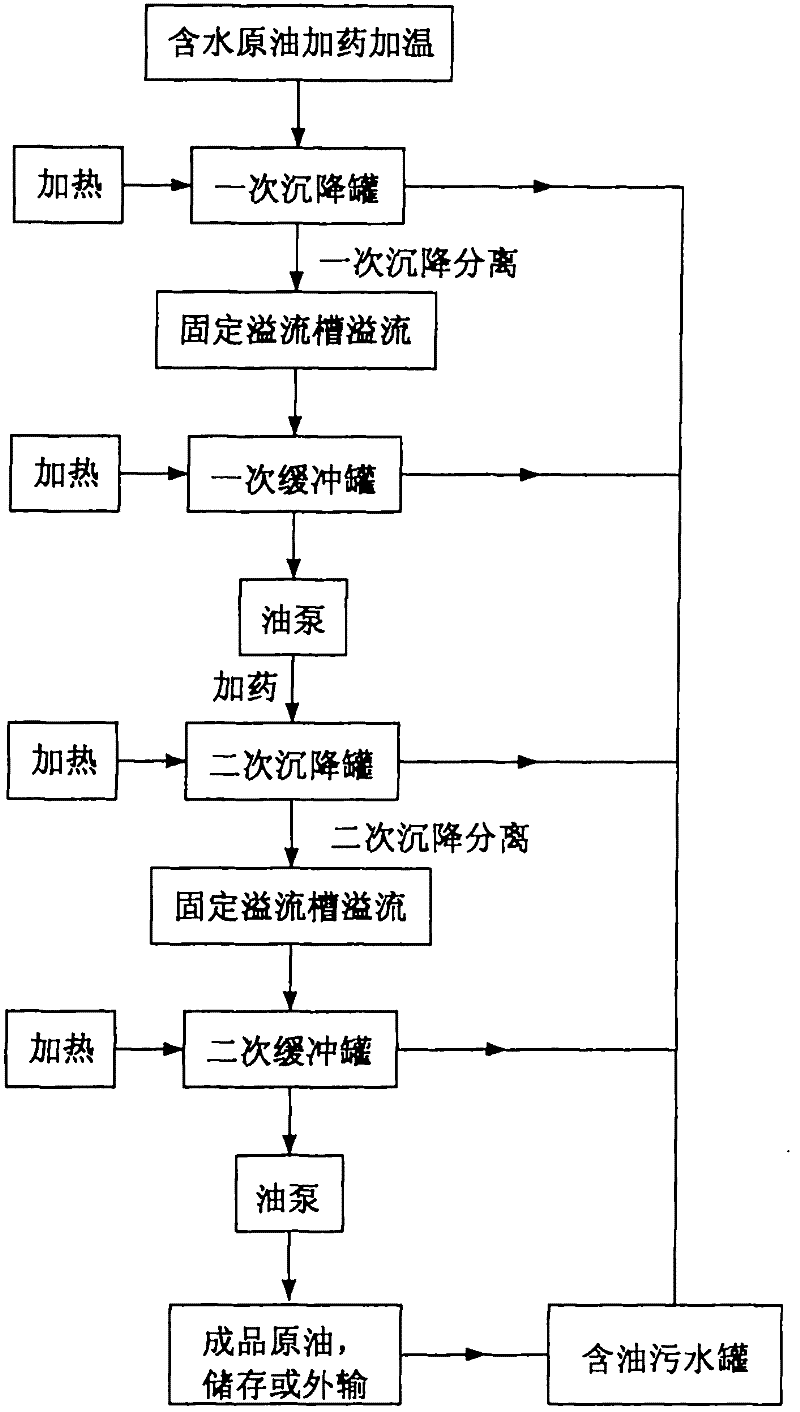

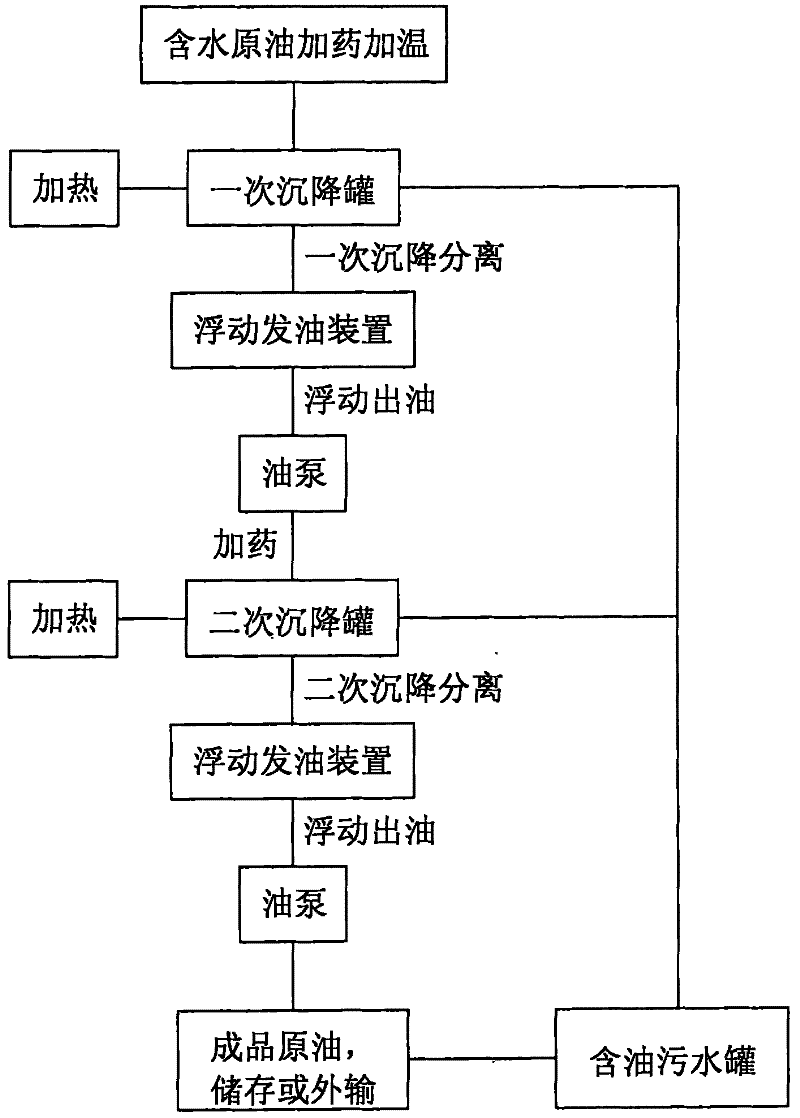

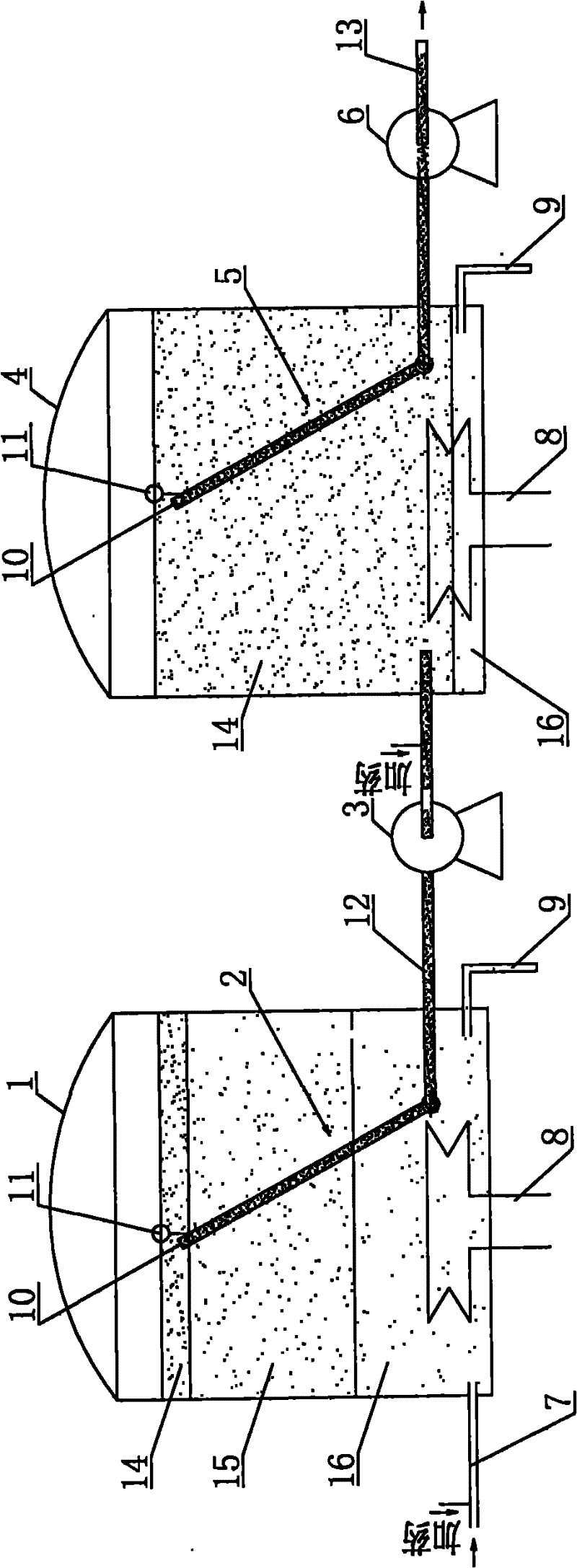

[0022] The process flow of crude oil floating oil out sedimentation dehydration of the present invention is mainly composed of subsidence dehydration in the tank, floating oil delivery and oil pumping outside the tank. According to needs, one-time sedimentation dehydration treatment can be used, and two primary sedimentation can be used in series to form a secondary dehydration process. Settling and dehydration treatment, only one settling tank is used for this settling treatment. Such as figure 2 and image 3 As shown, preferably, the crude oil floating oil outlet sedimentation dehydration process adopts secondary sedimentation dehydration treatment, and the equipment and devices used mainly include two sedimentation dehydration oil outlet devices with the same structure and the oil inlet pipe 7, the oil pump and the outer outlet oil pipe 13 . Taking the primary sedimentation dehydration oil extraction device as an example, it includes a primary sedimentation tank 1, a pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com