Conductive-rubber-based flexible array clip pressure sensor and manufacturing method

A pressure sensor, flexible array technology, applied in the measurement, printing, printing device and other directions of applying the properties of piezoelectric resistance materials, can solve the problems of heavy weight, high manufacturing cost, inconvenient operation, etc., to promote application prospects and Range of applications, long service life, simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

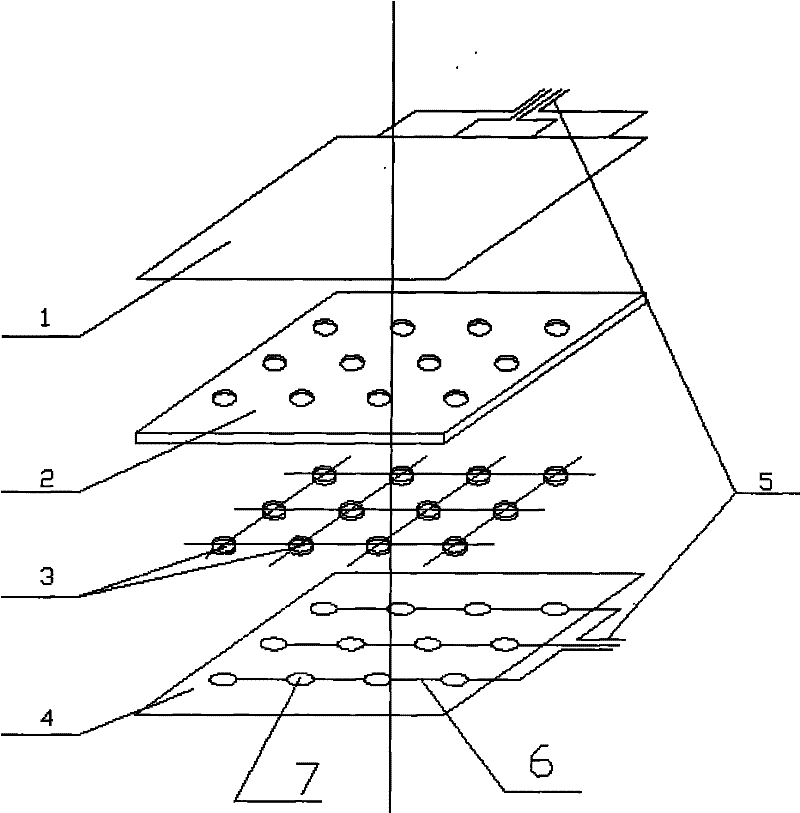

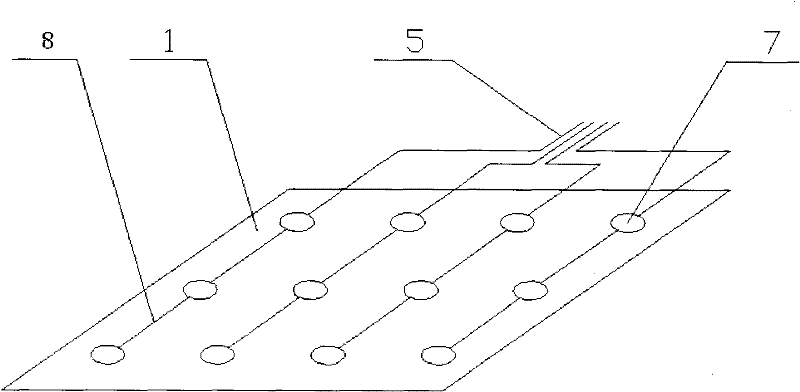

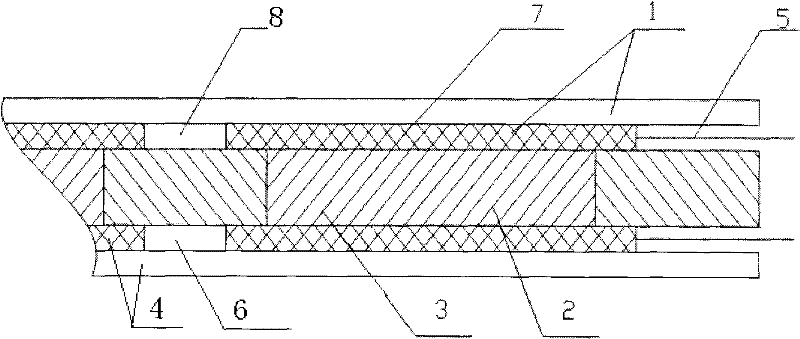

[0020] refer to figure 1 , figure 2 , image 3 , a flexible array chip pressure sensor based on conductive rubber, including an upper electrode layer 1 and a lower electrode layer 4, the lower surface of the upper electrode layer 1 is printed with vertical upper electrode lines 8, and the upper surface of the lower electrode layer 4 is printed with The horizontal lower electrode line 6 is printed with a circular electrode circle 7 on the lower surface of the upper electrode layer 1 and the upper surface of the lower electrode layer 4 and where the upper electrode line 8 and the lower electrode line 6 intersect, and the electrode circle 7 is provided. There is a rubber pressure-sensitive unit 3, a silicone rubber gasket 2 is provided where the upper electrode layer 1 and the lower electrode layer 4 do not have a sensitive element 3, the rubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com