High-efficient full-spectrum silicon-based double-knot photovoltaic cell

A photovoltaic cell, full-spectrum technology, applied in the field of solar energy applications, can solve the problems of large investment, long processing time, unfavorable production efficiency, etc., and achieve the effects of high production efficiency, low production cost, and overcoming the discontinuity of the interface electric field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

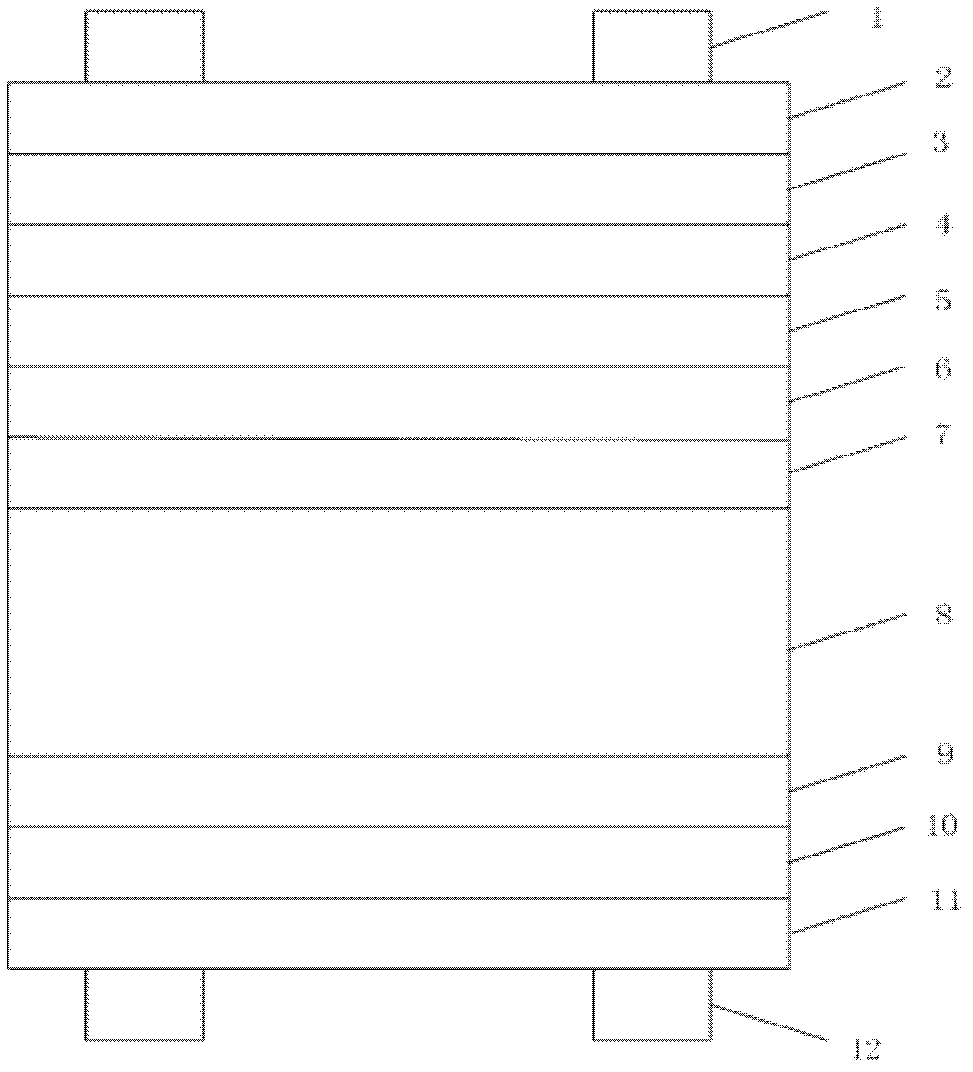

[0016] refer to figure 1 Shown: 1. front silver electrode, 2. front TCO conductive film, 3. front p-type nano-silicon layer, 4. i-type nano-silicon layer, 5. front n-type nano-silicon layer, 6. p-type nano-silicon layer, 7. Front nano-silicon buffer layer, 8. n-type single crystal silicon, 9. Back nano-silicon buffer layer, 10. Back n-type nano-silicon layer, 11. Back TCO conductive film, 12. Back silver electrode.

[0017] by figure 1 The sequence shown is an example, and the preparation process includes the following steps:

[0018] (1) Select an n-type single crystal silicon wafer, the resistivity of the silicon wafer is 1-3 Ω·cm, the thickness of the silicon wafer is about 200 μm, and the silicon wafer is polished with a concentration of 20% sodium hydroxide solution, and the silicon wafer after cleaning The sheet is a polished sheet, which requires a bright surface without spots, scratches, or water marks.

[0019] (2) Deposit a nano-buffer layer and an n-type nano-sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical band gap | aaaaa | aaaaa |

| optical band gap | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com