Growth method for sapphire crystals and crystal growth furnace structure for growing sapphire crystals

A technology of sapphire crystal and growth method, applied in the field of growth method and crystal growth furnace structure for growth, can solve the problems of crystal quality and size limitation, long time required for high temperature crystal growth, impurity pollution, etc., and achieves high measurement and processing accuracy , The effect of process control and operation is convenient and high processing precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific drawings and embodiments.

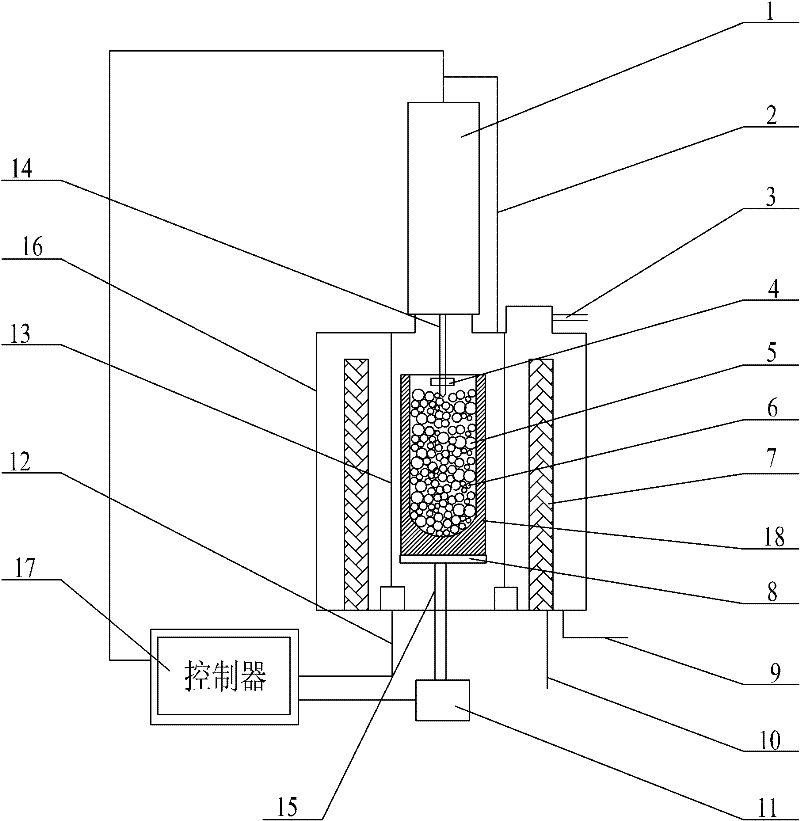

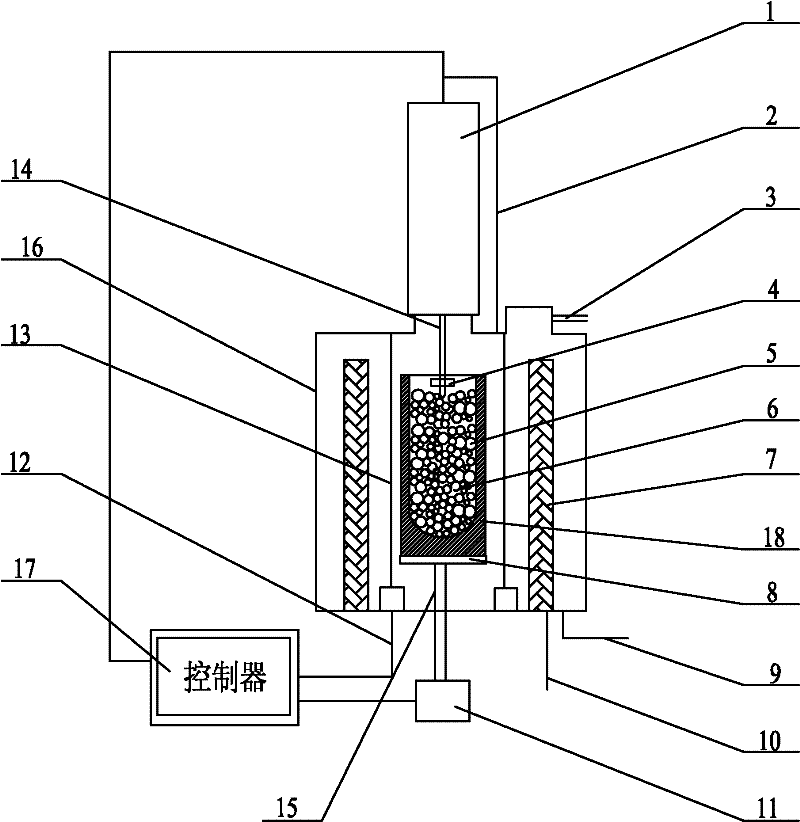

[0032] Such as figure 1 Shown: the structure of the crystal growth furnace used for sapphire crystal growth in the present invention includes an upper rotating motor 1, a CCD video sensor 2, a gas pipe 3, a seed crystal 4, a first alumina crystal block 5, a second alumina crystal block 6, Insulation layer 7, rotating support table 8, water inlet 9, water outlet 10, lower rotating motor 11, thermocouple 12, thermal field 13, seeding column 14, rotating support shaft 15, furnace body 16, controller 17 and crucible 18 .

[0033] Such as figure 1 As shown: the lower part of the furnace body 16 is provided with a rotary support platform 8 for placing a crucible 18, the rotary support platform 8 has a table surface, and the crucible 18 is placed on the table surface; the rotary support platform 8 corresponds to the table surface The other side is protrudingly prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com