Overflow dyeing system of gas flow atomization dyeing machine and water using method thereof

An overflow dyeing and airflow atomization technology, applied in the field of overflow dyeing system, can solve the problems of high fan power, high energy consumption, high power consumption, etc., to save energy, expand the scope of application, and reduce the power consumption at the bottom Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

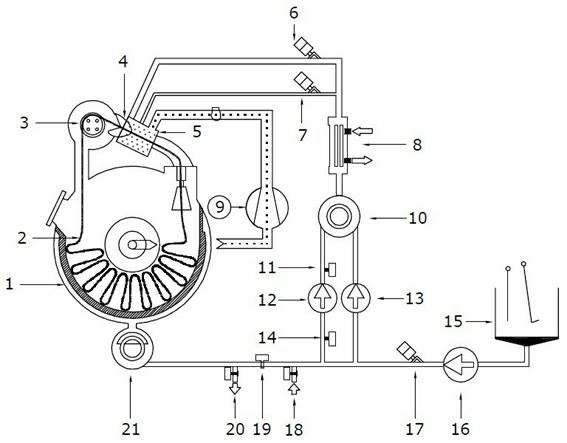

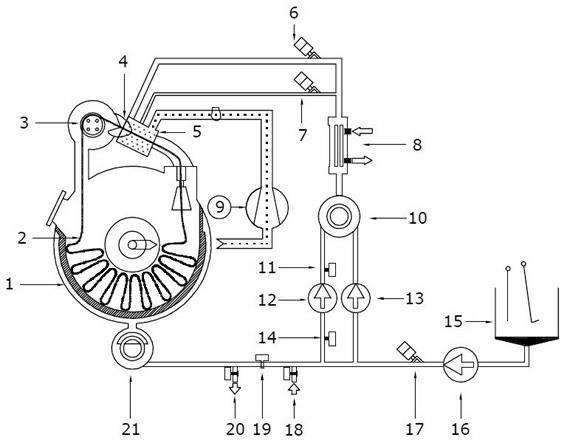

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

[0021] An overflow dyeing system of an air atomization dyeing machine, comprising a cylinder body 1, a gray cloth 2, a cloth guide wheel 3, an air flow nozzle 5, an air flow nozzle connecting pipe valve 7, a heat exchanger 8, a fan 9, and a main pump 13. Feed barrel 15, feed pump 16, feed valve 17, water inlet valve 18, discharge valve 20, connection valve III 19, filter screen II 21, filter screen I 10 is set between the main pump 13 and heat exchanger 8, On the output pipeline of heat exchanger 8, overflow nozzle 4 is connected and set through overflow nozzle connecting pipe valve 6, and overflow nozzle 4 is positioned at the top of air flow nozzle 5; The connecting valve I11 and the connecting valve II14 are respectively arranged on the pipelines at both ends of the additional pump 12, and the connecting valve III19 is arranged between the water inlet valve 18 and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com