Rotary power head of cosine tooth profile drilling machine

A power head and tooth profile technology, applied in rotary drilling rigs, drilling equipment, earth-moving drilling, etc., can solve the problems of large radial size, low center of mass, poor dynamic balance characteristics, etc., and achieve small radial size and transmit torque. Large and easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

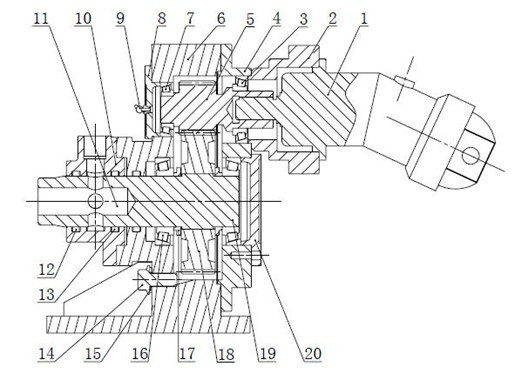

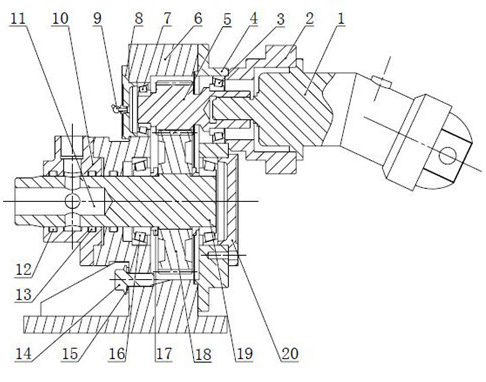

[0008] The technical content of the present invention will be further described in conjunction with the accompanying drawings.

[0009] Such as figure 1 As shown, the input gear shaft 5, the large gear 18 and the output shaft 11 form a cosine tooth profile transmission transmission device, the cover plate 4 is fixed on the machine base 6, the flange 2 is fixed on the cover plate 4, and the input gear shaft 5 is respectively connected to the bearing A3, the bearing B7 is supported on the cover plate 4 and the machine base 6, the motor 1 is fixed on the flange 2, and connected with the input gear shaft 5, the output shaft 11 is respectively supported on the machine base 6 and the cover plate with the bearing C16 and the bearing D19 4, the joint type pressure oiling cup 9 passes through the small end cover 8 at the end of the input gear shaft 5 and is connected to the input gear shaft 5. There is an air inlet hole on the air chamber 10, and the air chamber 10 is fixed on the mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com