Cabin dehumidificating and desalting micro positive pressure system of wind generating set at sea and in intertidal zone

A technology of micro-positive pressure for wind turbines, applied to wind turbine components, wind engines, wind power generation, etc., can solve problems such as low reliability, complicated operation, corrosion and short circuit, etc., to ensure service life and meet technical requirements High, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

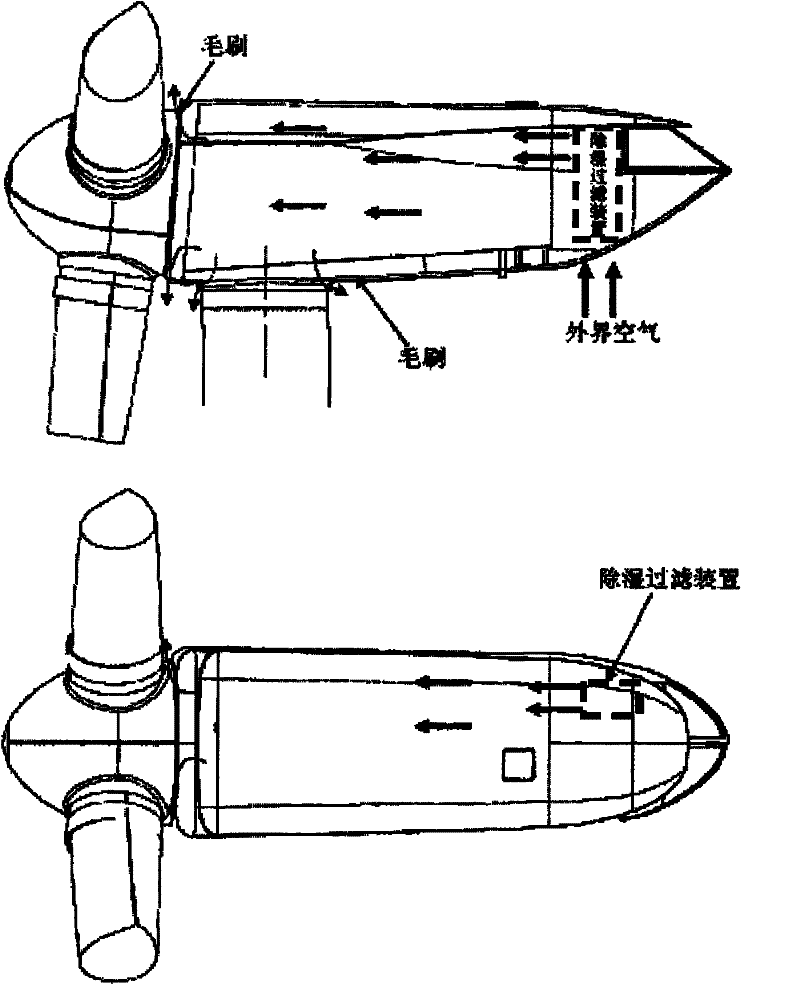

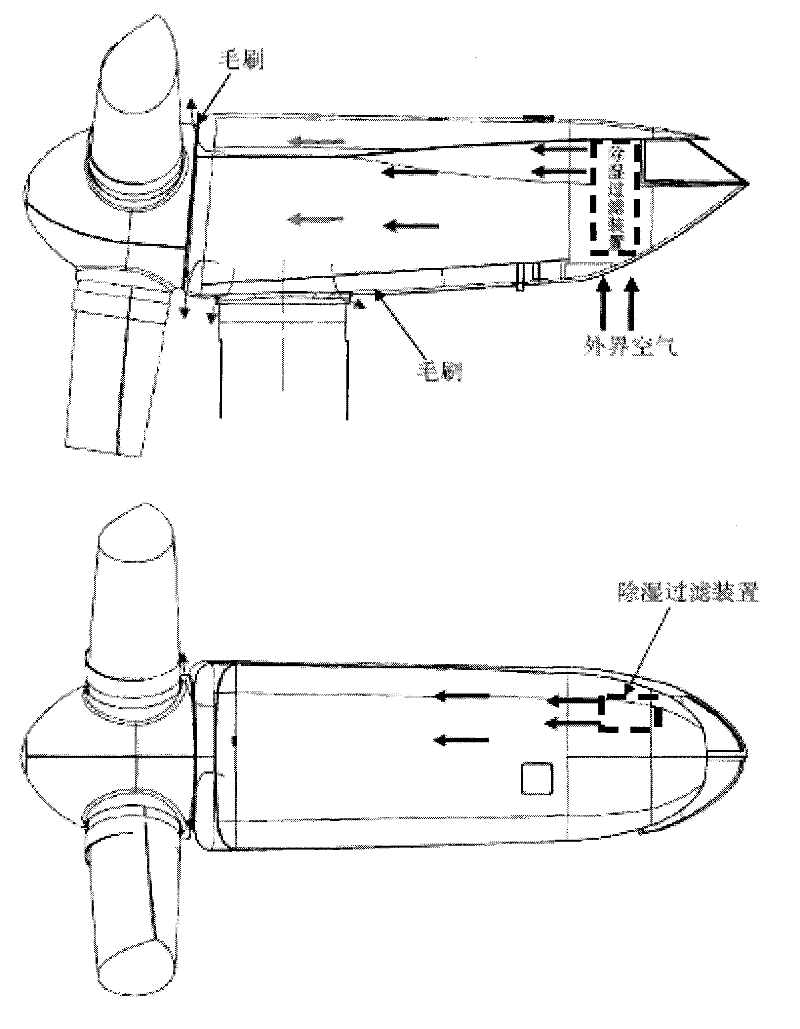

[0017] The diagram of the desalination and dehumidification air intake system in the engine room is shown in the attached figure;

[0018] The air intake system for desalination and dehumidification is located at the rear end of the engine room. Relatively independent air passages have been established for the generator and the gearbox cooler. A relatively airtight space is formed inside.

[0019] The desalination and dehumidification device set up at the air inlet ensures that the air entering the cabin is in an appropriate temperature range by condensing and dehumidifying the air and controlling the temperature of the air entering the cabin through the condensing device and the heating device, so as to ensure that the cabin will not High temperature or film of water condensed on the metal surface. At the same time, filter components are added to the desalination and deh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com