In-situ dynamic sampling monitoring method and device for soil and underground water repair

A technology for groundwater remediation and dynamic sampling, which is applied in the direction of measuring devices, sampling devices, instruments, etc., can solve the problems of high cost, time-consuming, and inability to control and provide, and achieve the effect of low cost, convenient operation, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

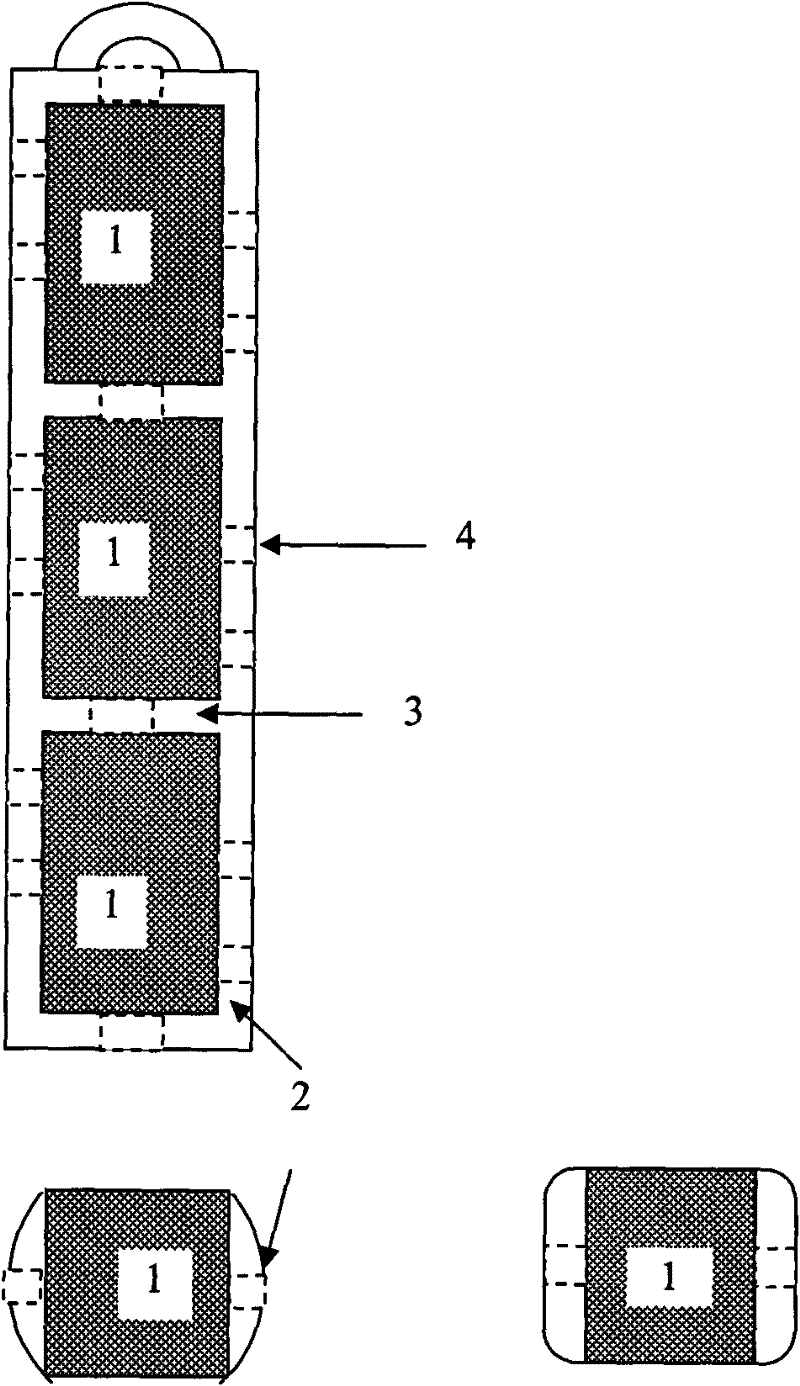

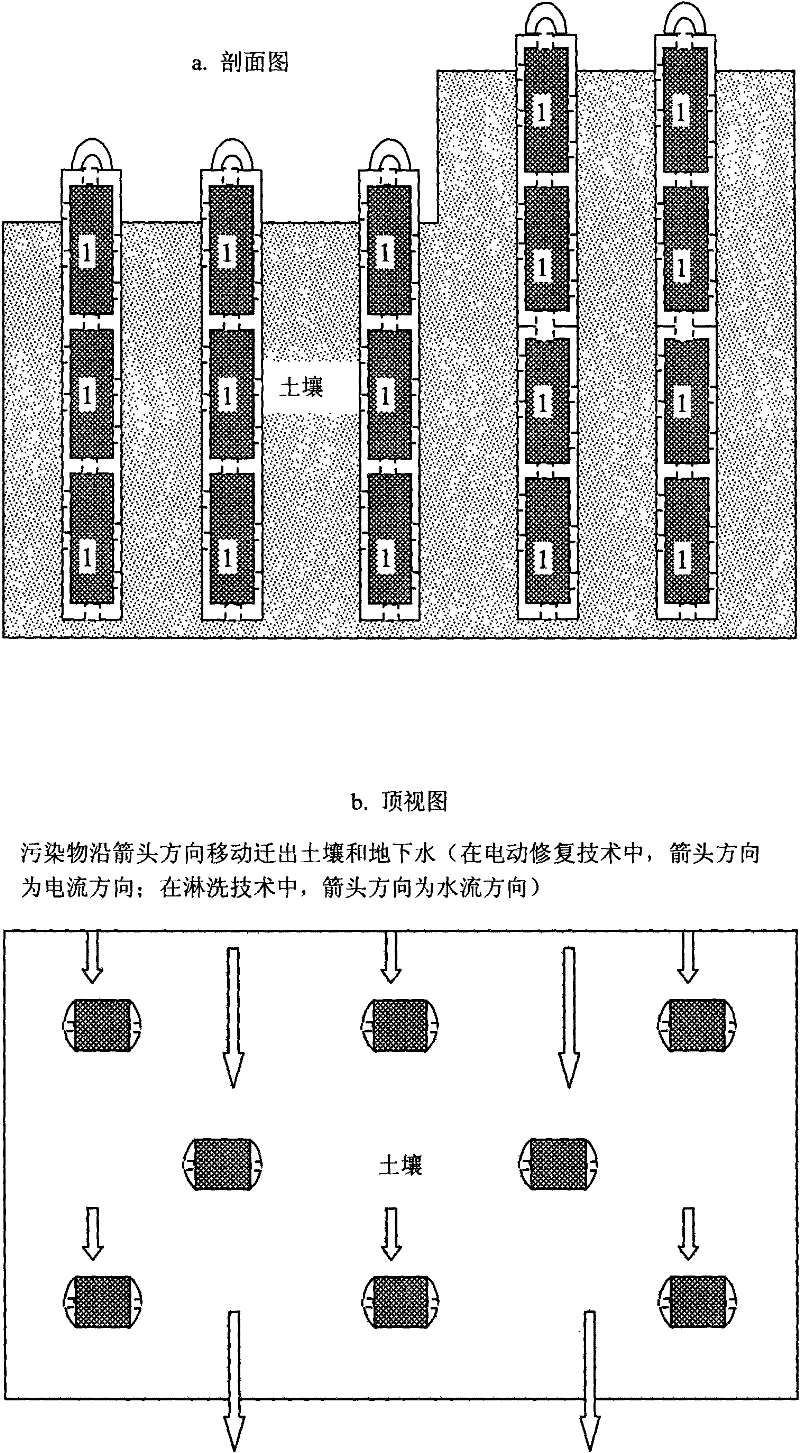

[0016] (1) According to the requirements of the restoration plan, use manual excavation or mechanical drilling to excavate sampling holes in the restoration site, and the diameter of the sampling holes should be slightly larger than figure 1 and figure 2 The outer diameter of the in-situ dynamic sampling device shown, the depth of the sampling hole is determined by the repair scheme. The soil excavated when digging holes should be placed in order of depth for use in (3);

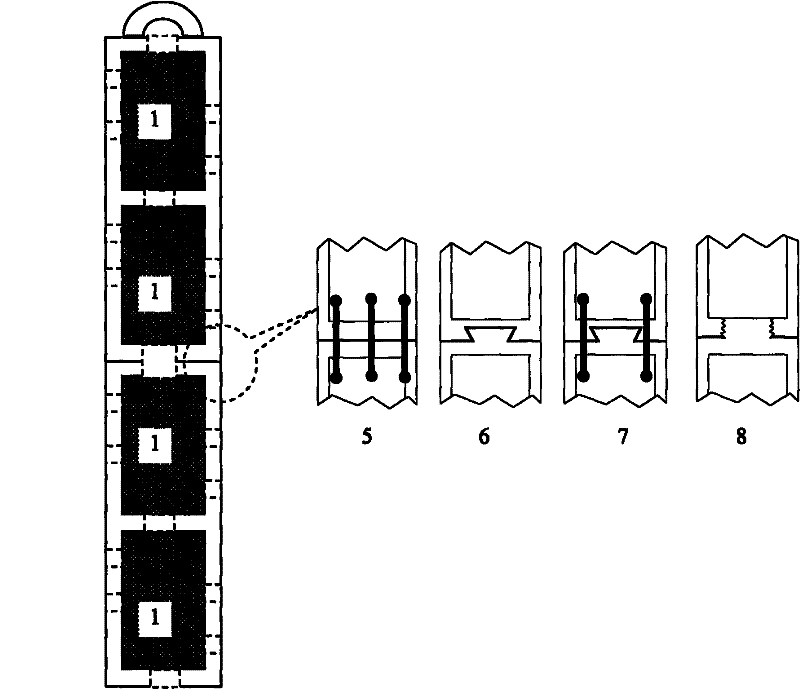

[0017] (2) According to the depth of the sampling hole, select in-situ dynamic sampling devices of different lengths. For deeper sampling holes, use figure 2 The module splicing form shown increases the length of the sampling device;

[0018] (3) Fill the soil dug out in the step (1) into the cavity in the middle of the sampling device according to the original upper and lower order, and compact and smooth;

[0019] (4) Mark the depth position of each monitoring point in the monitoring hole on the devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com