Quality homogenized evaluation method for multi-spot produced cigarette products and difference index screening method

A technology of product quality and difference indicators, applied in the fields of instruments, data processing applications, calculations, etc., can solve problems such as no public reports, and achieve the effects of strong operability, comprehensive test results, and novel methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The specific steps of the multi-point production cigarette product quality homogenization evaluation method and the screening method of the difference index of the present invention are as follows:

[0038] (1) Preparation of samples and their determination indicators:

[0039] Select a certain brand of a certain tobacco group, finished cigarettes produced by different manufacturers, and conduct sampling according to GB / T5606.1 Cigarette Part 1: Sampling, for operation. The pretreatment of the standard sample and each sample is carried out according to the atmospheric environment of GB / T16447 tobacco and tobacco products, adjustment and test (GB / T16447-2004, ISO 3402; 1999, IDT), and then the detection of the following indicators is carried out:

[0040] Smoke components: smoke tar content, smoke nicotine content, carbon monoxide content, smoke moisture;

[0041] Chemical indicators: nicotine nitrogen, reducing sugar, nicotine content

[0042] Sensory indicators: arom...

Embodiment 2

[0079] The preparation and detection methods of the sample are the same as in Example 1, and the measurement indicators are based on the 19 indicators in Example 1, except for one indicator—reducing sugar, taking 18 indicators as an example.

[0080] Calculation method of the acceptable lower limit of F1 of the main factory of grade A:

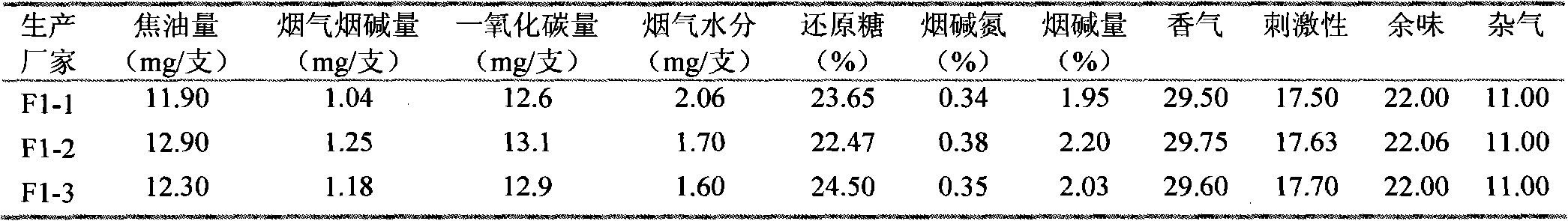

[0081] Define the manufacturer F1 as the main manufacturer, and the three batches of the main manufacturer F1 are F1-1, F1-2, and F1-3. Under the premise of routine inspection of product quality, using the test results of 18 indicators, As shown in Table 1-1 and Table 1-2, the original data of each index of cigarettes among the three batches of main manufacturers.

[0082] Table 1-1 Raw data of various indicators of cigarettes between batches of major manufacturers

[0083]

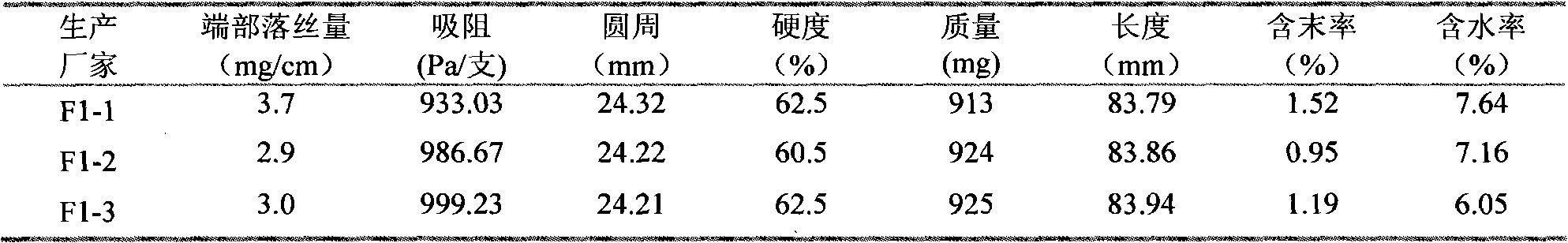

[0084] Table 1-2 Raw data of each index of cigarettes between batches of major manufacturers

[0085]

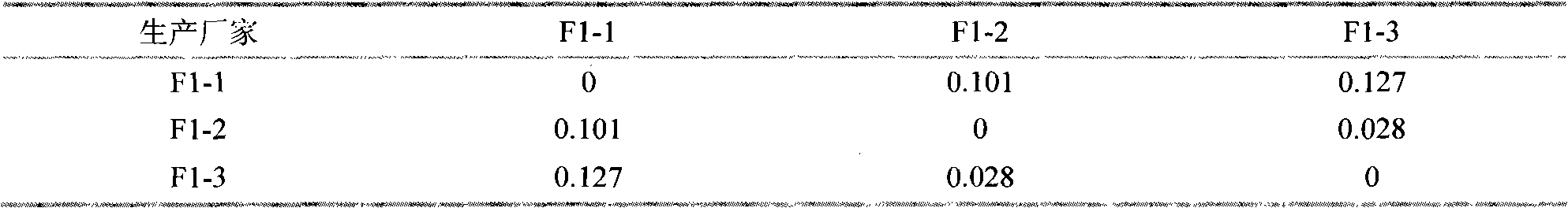

[0086]

[0087] Euclidean distance, Z-score standardiza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com