Glow plug with metallic heater probe

一种热探针、电热塞的技术,应用在电路、电阻器、电气元件等方向,能够解决电热塞成本增加等问题,达到避免高应力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

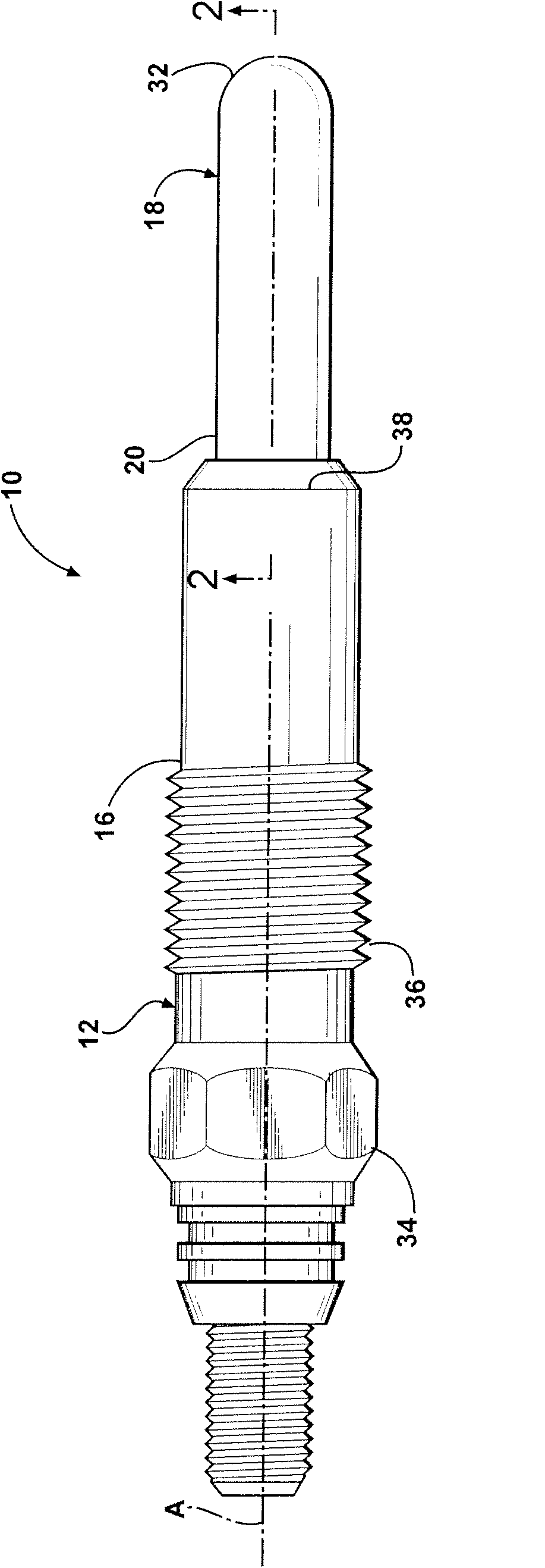

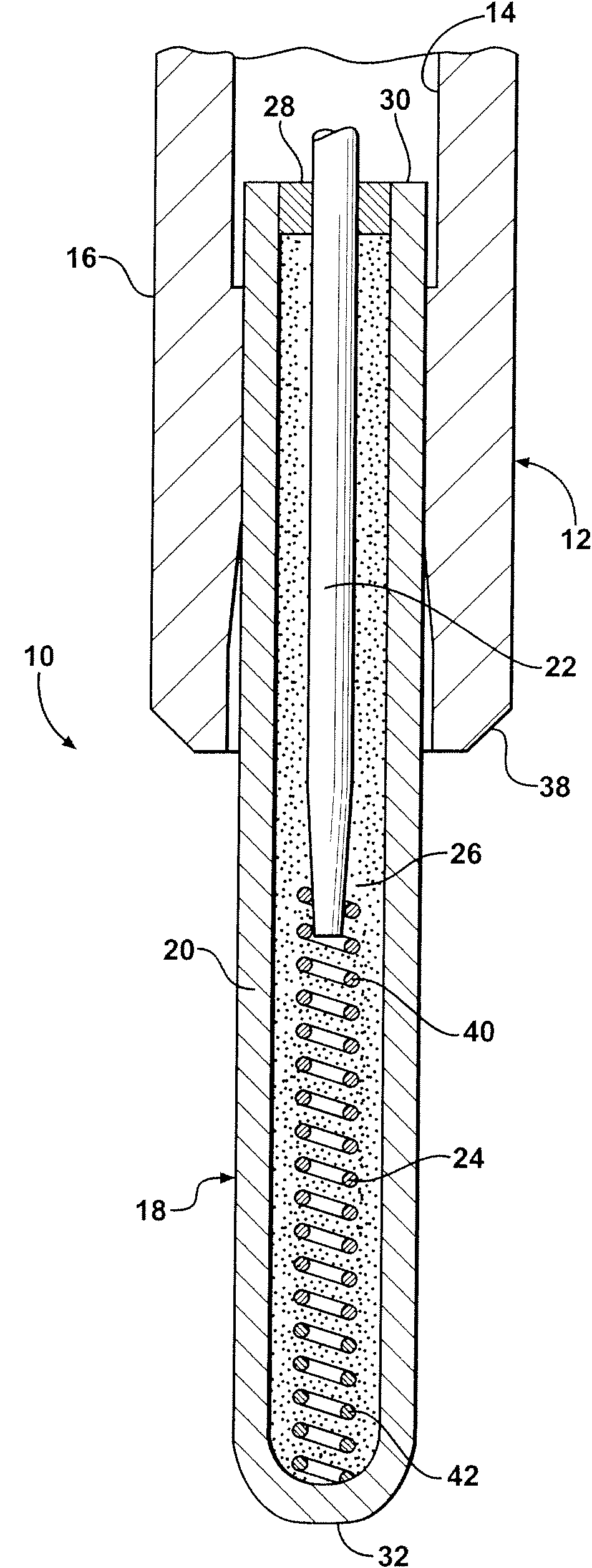

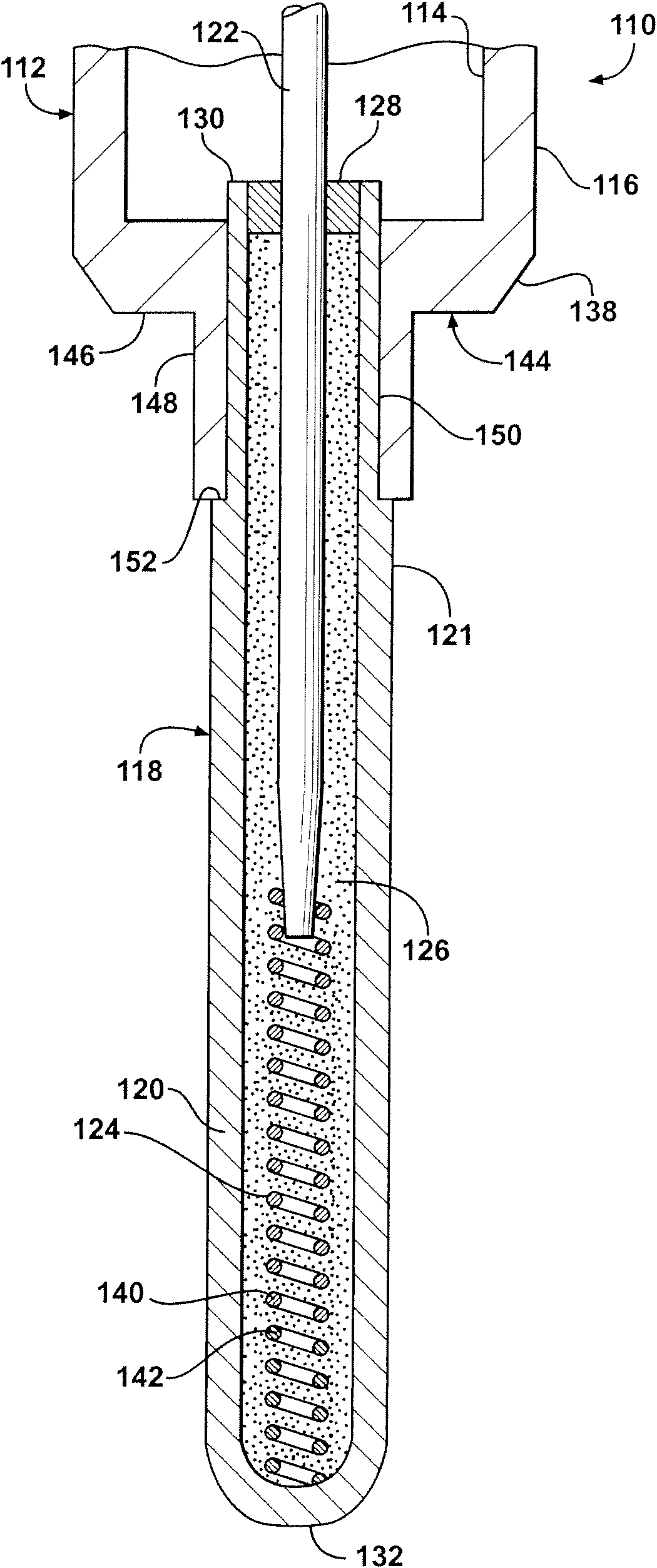

[0018] Referring to the drawings, wherein like numerals indicate like or corresponding parts in the various figures, a glow plug according to the prior art is shown generally at 10 in FIGS. 1 and 2 . The glow plug 10 comprises an annular metal casing 12 having a bore 14 extending along an imaginary longitudinal axis A. As shown in FIG. Housing 12 may be made of any suitable metal, such as various steels. Housing 12 may also include a plating or coating, such as nickel or a nickel alloy, on some or all of its surfaces, including outer surface 16 and the interior of bore 14, to enhance its resistance to high temperature oxidation and corrosion.

[0019] The glow plug assembly 10 includes a heat probe, indicated generally at 18 . Thermal probe 18 includes metal sheath 20 , electrode 22 , resistive heating element 24 , powder fill material 26 and seal ring 28 . The sheath 20 is an electrically and thermally conductive member of generally tubular construction. Any suitable metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com