Intelligent fluidization balancing device of bulk cement semitrailer and using method

A technology of bulk cement and balancing device, applied in the direction of conveying bulk materials, transportation and packaging, conveyors, etc., can solve problems such as excessive pressure and safety valve exhaust, avoid excessive pressure, and improve unloading speed and efficiency. , the effect of avoiding failure problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

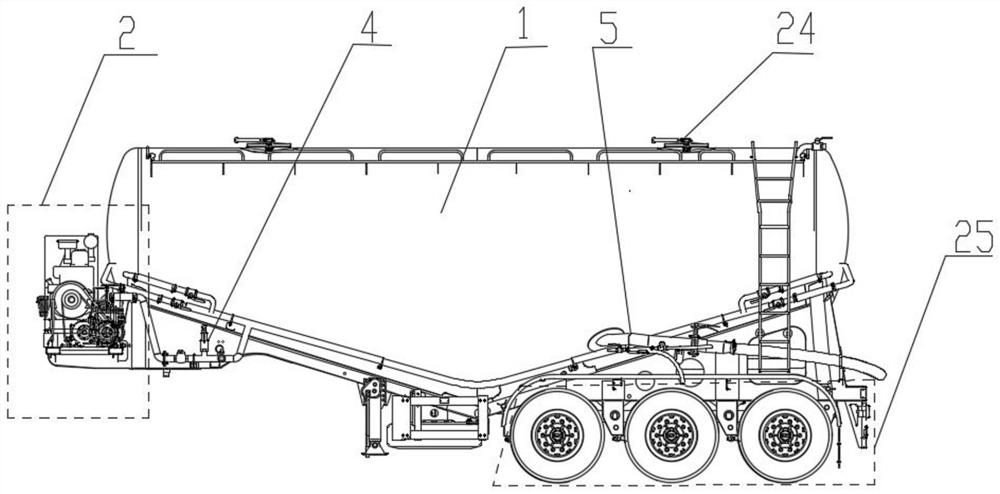

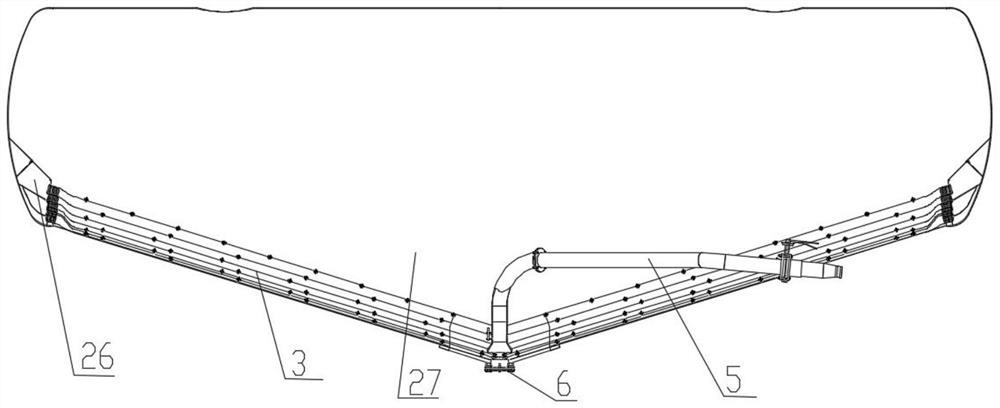

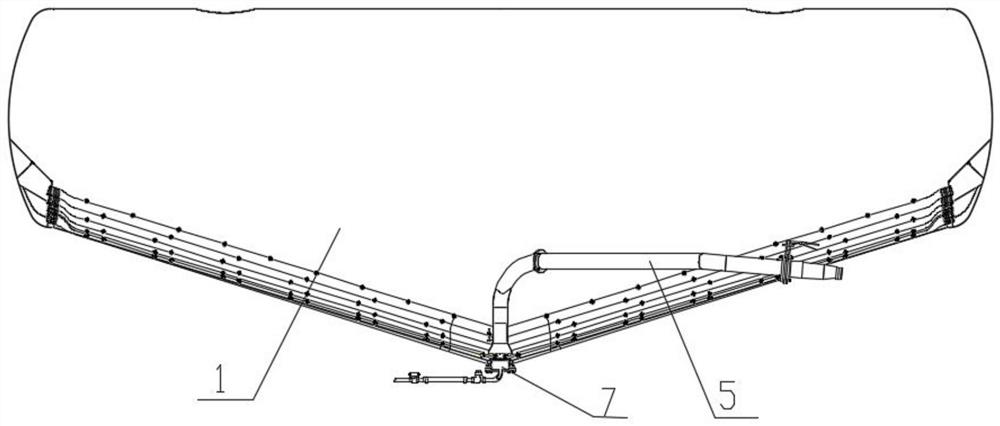

[0045] Such as Figure 1 to Figure 7 Shown: an intelligent fluidized balance device for a bulk cement semi-trailer, including a tank body 1 and a gas source 2, a fluidized bed 3 is arranged inside the tank body 1, the fluidized bed 3 is located at the bottom of the inner wall of the tank body 1, and the tank body 1 The inlet pipeline 4 and the discharge pipeline 5 are connected, and the inlet pipeline 4 and the discharge pipeline 5 are respectively detachably connected with the tank body 1. The inner wall of the tank body 1 is "V" shape, and the bottom of the tank body 1 is provided with a sewage outlet 6;

[0046] After compressed air enters the head side plate air chamber 27 at both ends of the tank body 1, it flows through and passes through the fluidized bed 3 to fluidize the bulk cement in the tank body charging space 28. The longitudinal section of the fluidized bed 3 is the High and low in the middle, and the horizontal circular section is also high on both sides and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com