Metal bar clamping type double-stage shearing blanking device and blanking method

A clamping type, metal bar technology, applied in the direction of shearing device, metal processing equipment, shearing machine equipment, etc., can solve the problem of reducing the utilization rate of raw materials, improve the working efficiency of blanking, avoid tilting, and uniform force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

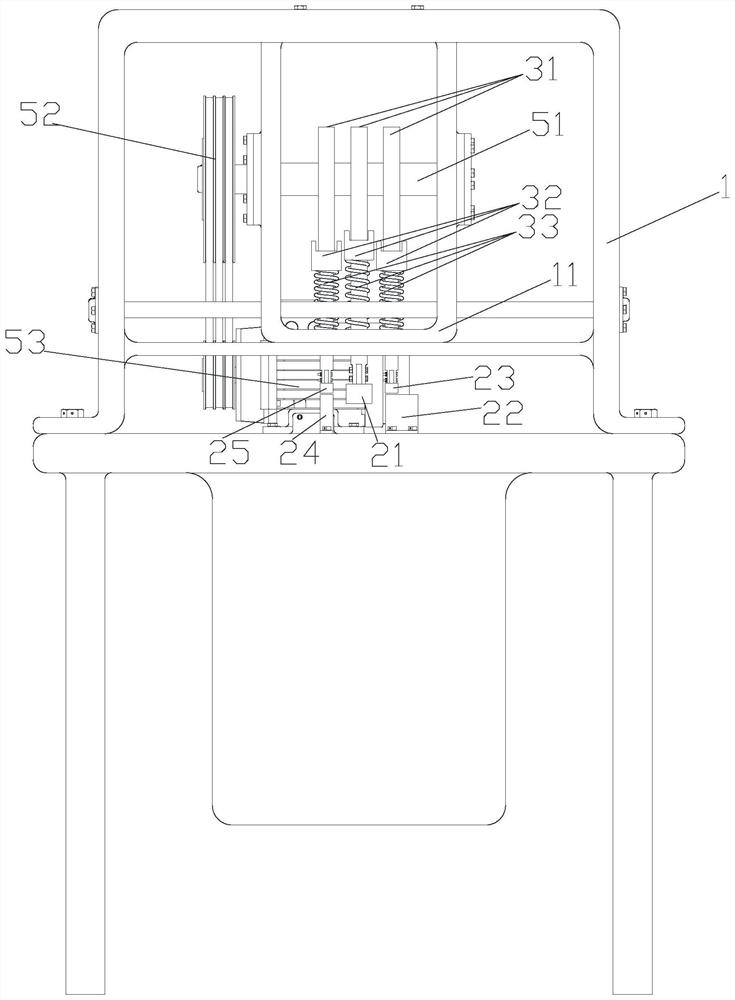

[0055] Such as Figure 1-9 As shown, this embodiment provides a metal rod clamping type double-stage shearing blanking device, including a housing, and the housing 1 is provided with a pressing blanking unit and a cam mechanism;

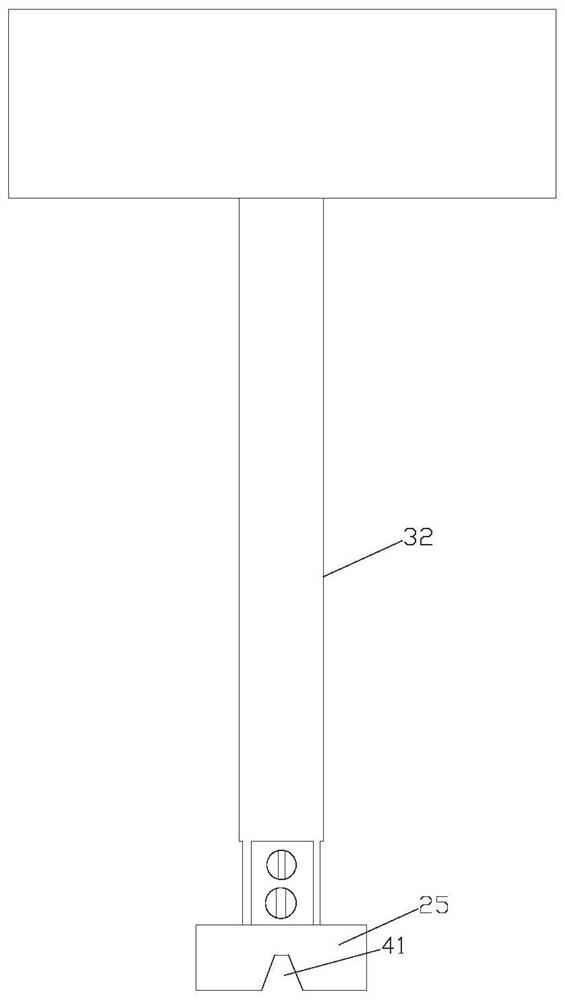

[0056] The pressing and blanking unit includes a cutter, a first pad 22, a first pressure block 23, a second pad 24 and a second pressure block 25, and the first pad 22 is arranged opposite to the first pressure block 23 Below and the first spacer 22 is fixed in the housing 1, the second spacer 24 is arranged directly below the second pressing block 25 and the second spacer 24 is fixed in the housing 1;

[0057] The cam mechanism includes a first cam assembly for driving the first pressing block 23 close to or away from the first cushion block 22, a second cam assembly for driving the tool to move, and a second cam assembly for driving the second pressing block 25 close to or away from the first cushion block 22. a third cam assembly away from the s...

Embodiment 2

[0075] This embodiment provides a method for shearing and blanking using the metal rod clamping type double-stage shearing and blanking device of Example 1, including the following steps:

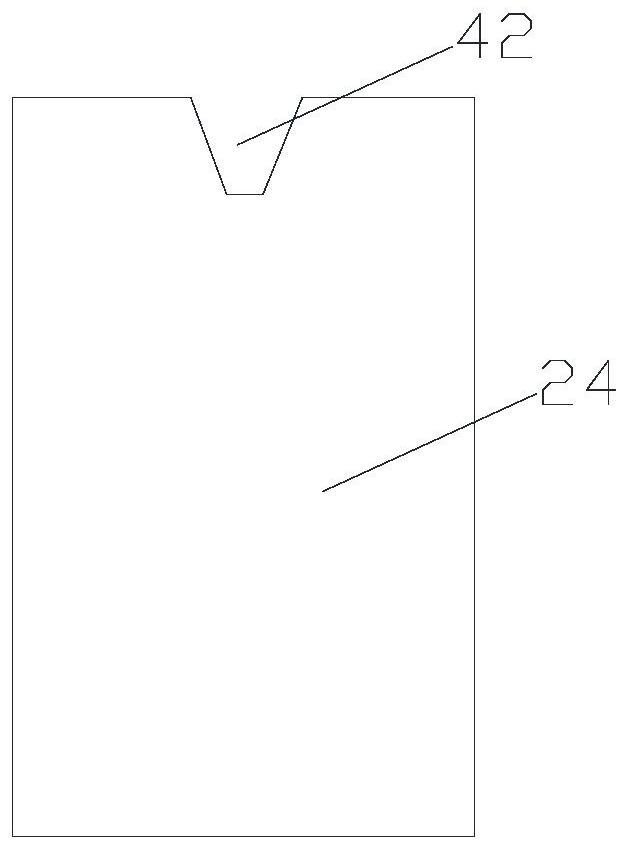

[0076] Step 1. Select a metal bar stock with a material of 304 stainless steel, a length of 40 mm, and a diameter of 10 mm. A V-shaped incision 43 is pre-cut on the bar stock. The incision 43 includes a metal bar located inside the bar stock. The rounded tip and the opening extending from the rounded tip to the bar surface, the fillet radius of the rounded tip is 0.2mm, the depth of the cutout 43 is 1.5mm, the number of cutouts 43 There are four, the four cutouts 43 are divided into two groups, the cutouts 43 of the two groups are arranged at intervals, the central axis line of the two cutouts 43 in the same group coincides and the central axis line is perpendicular to the rod The long axis of the material is obtained to obtain the bar material 4 to be sheared;

[0077] Step 2, adjust and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com