Air filter for diesel engine turbocharger

A technology of turbocharger and air filter, which is applied in the direction of fuel air filter, machine/engine, fuel air intake, etc., which can solve the problems of increasing pressure and diesel engine not working normally, and prevent the pressure from being too high. High, improve efficiency, ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

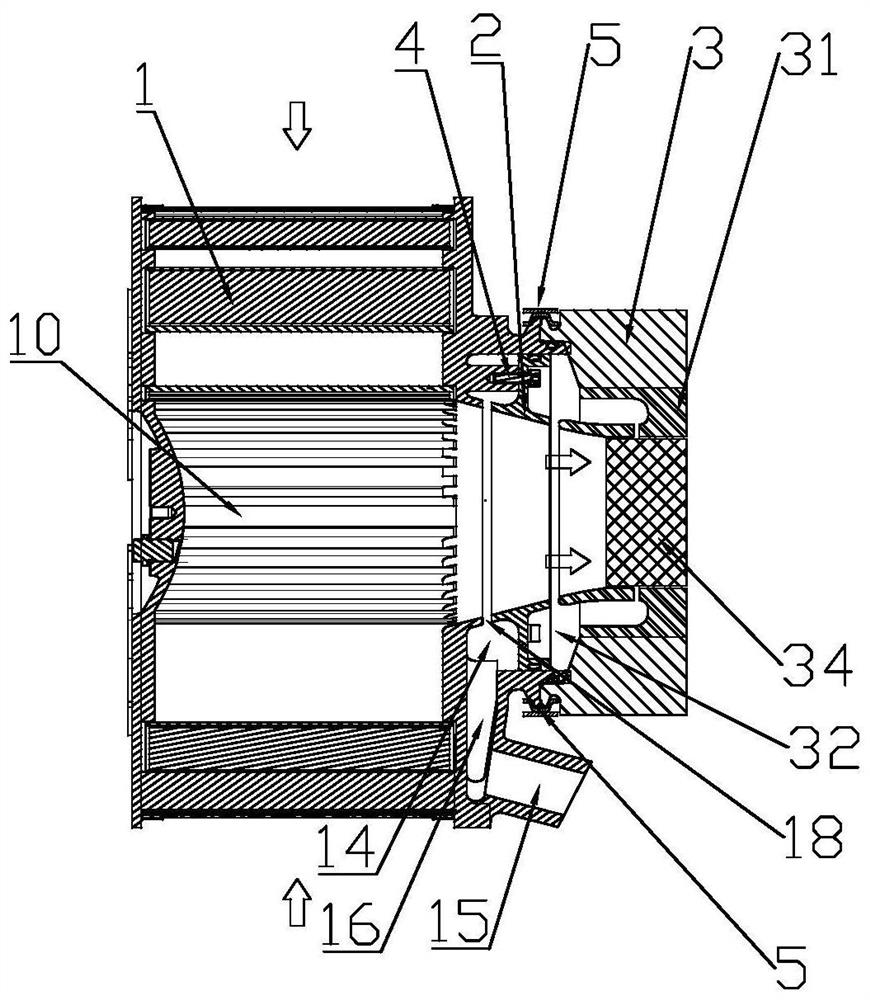

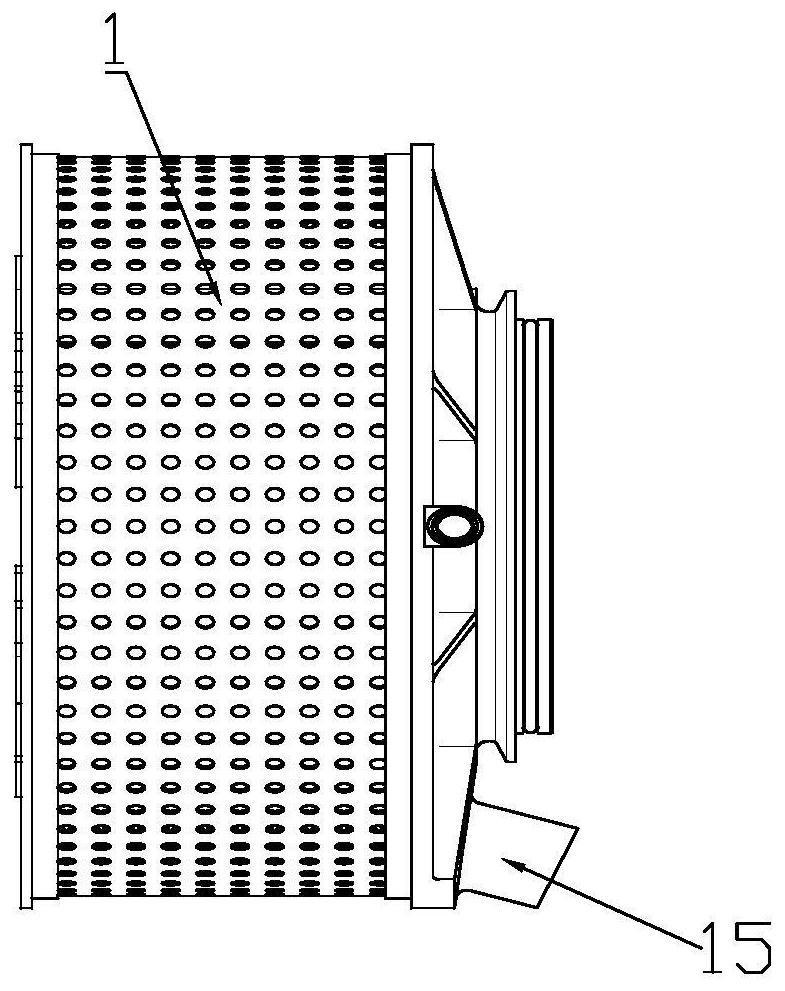

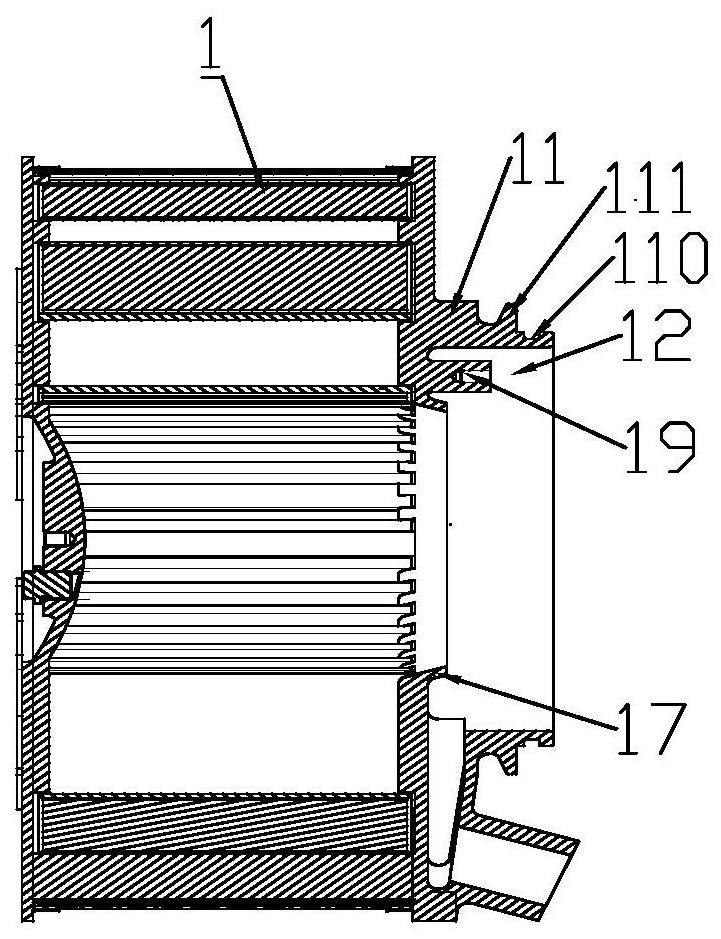

[0021] Such as figure 1 , figure 2 with image 3 Shown is the diesel engine turbocharger air filter disclosed by the present invention, including an air filter body 1 and an air filter cover plate 2;

[0022] The inner diameter of the air filter body is an air flow channel 10, and the air filter body is provided with an air filter structure (filter screen). Road 10 enters the turbocharger to drive the compressor wheel to work;

[0023] One end of the air outlet of the air filter body 1 is provided with a volute connecting portion 11 for connecting with the air inlet of the volute 3, and the inner diameter of the volute connecting portion 11 is larger than the inner diameter of the air filter body 1 to form an air filter. Cover accommodating chamber 12, the air filter cover accommodating cavity 12 is fixed with the air filter cover 2, the end face 13 of the air filter cover accommodating cavity away from the end of the volute and the air filter cover 2 An air inlet ring ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com