Rice field straw chopper

A technology of bellflower and paddy fields, applied in the field of paddy bellflower returning to the field, can solve the problems of poor economy, heavy operating load, and poor operating effect, and achieve the effects of reducing the amount of chemical fertilizers, increasing production, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

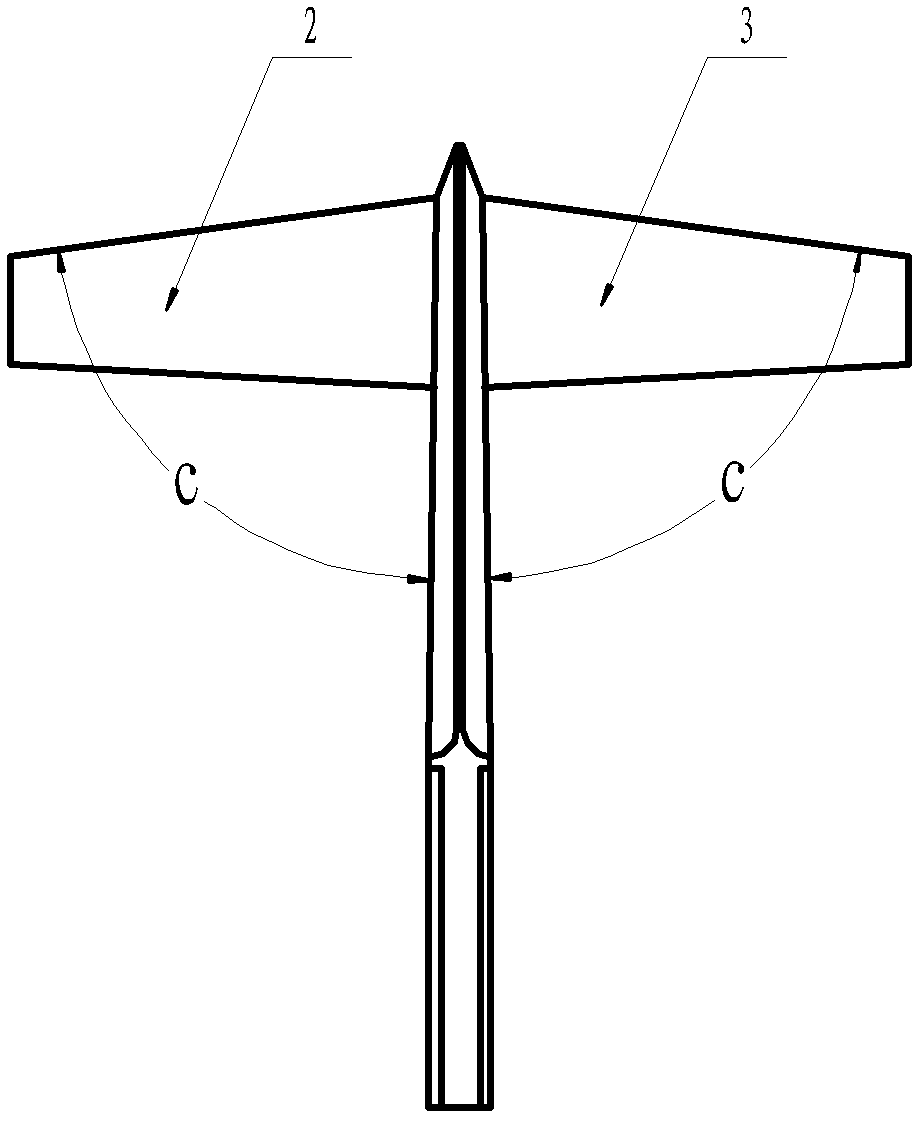

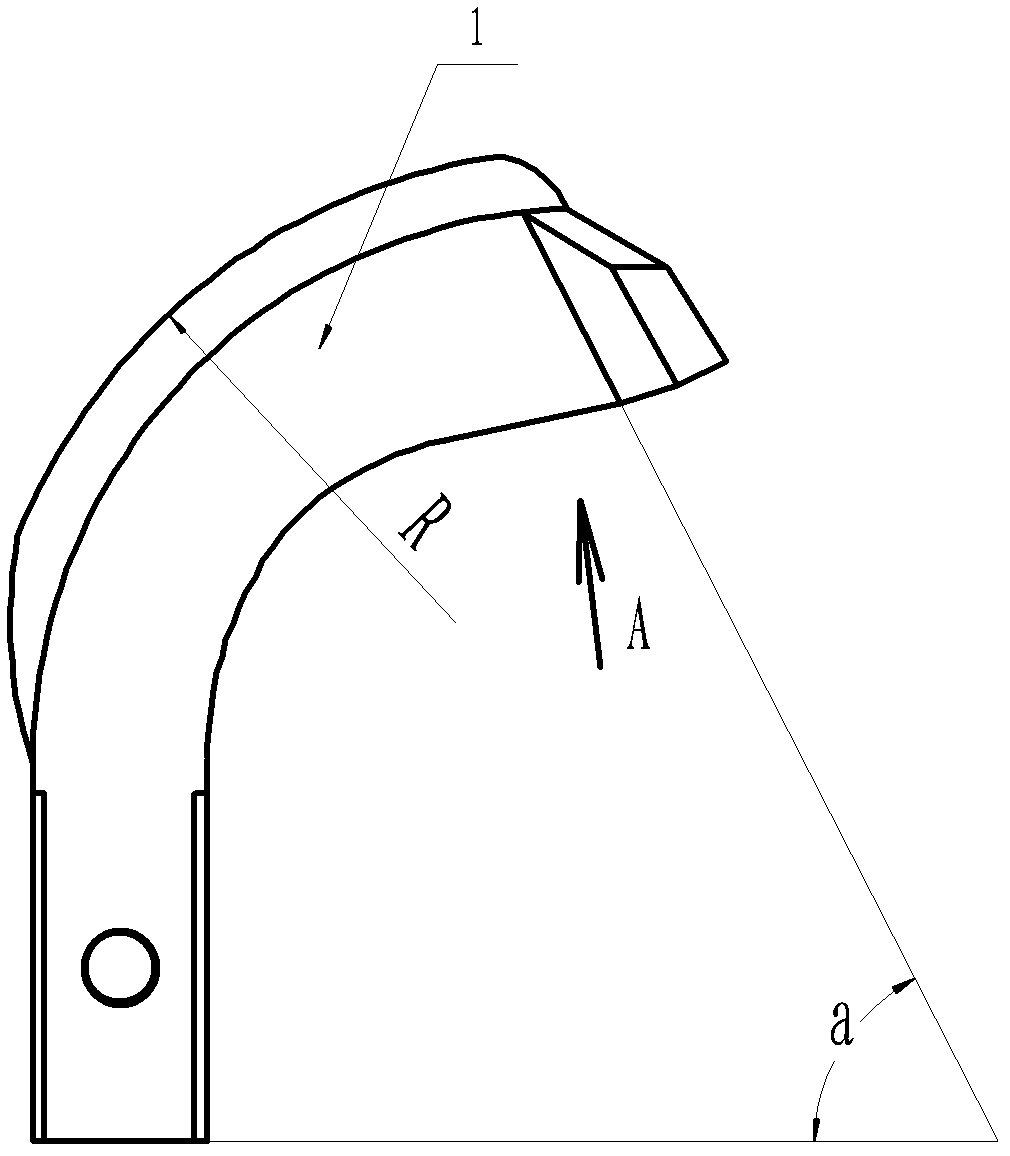

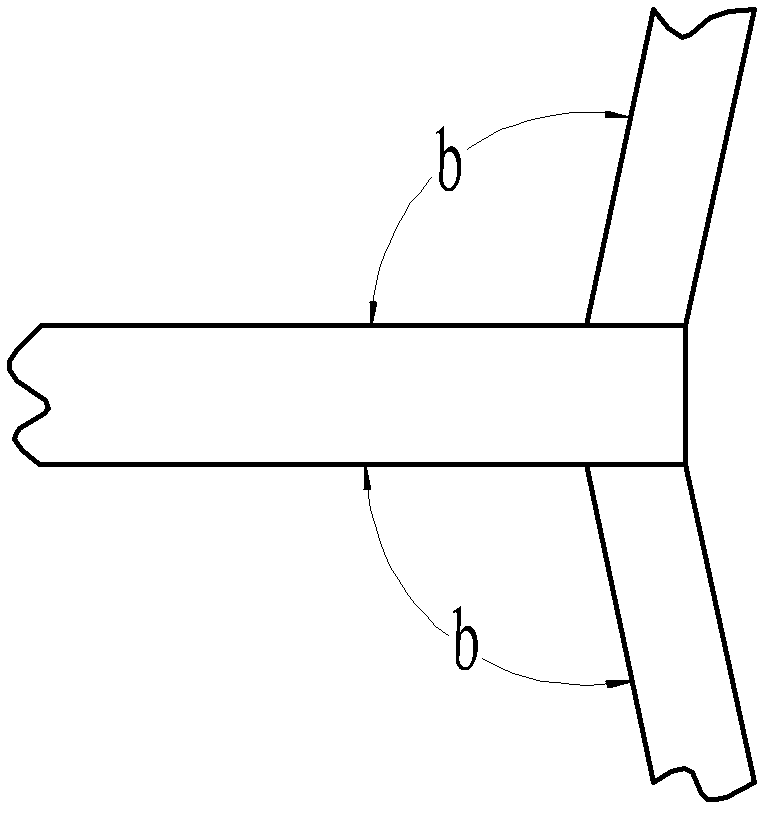

[0014] Example 1: A paddy field bellflower knife for returning to the field, including a longitudinal arc knife 1, a left transverse oblique knife 2, and a right transverse oblique knife 3, and the left transverse oblique knife 2 and the right transverse oblique knife 3 are respectively welded on the longitudinal On the arc knife 1; the radius of curvature R of the longitudinal arc knife 1 is 100 millimeters; the left transverse oblique knife 2 and the right transverse oblique knife 3 and the longitudinal arc knife 1 have a welding angle a of 55° in the front view direction, and The welding angle b in the side view direction is 155°, and the welding angle c in the bottom view direction is 140°.

Embodiment 2

[0015] Embodiment 2: The radius of curvature R of the longitudinal arc knife 1 is 105 mm, and the others are the same as in Embodiment 1.

Embodiment 3

[0016] Embodiment 3: The welding angle a of the left transverse oblique knife 2 and the right transverse oblique knife 3 and the longitudinal arc knife 1 is 70° in the front view direction, 160° in the side view direction b, and c in the bottom view direction Be 160 °, others are identical with embodiment 2.

[0017] When the invention is in use, it can be directly replaced on the cutter shafts of various existing rotary cultivators, and the installation and use are convenient. After soaking the straw and high stubble scattered by the combine harvester in water for 24 hours, the machine equipped with the platycodon grandiflorum returning knife is put into the field for operation. , covering straw and leveling the land and other operations, so as to realize the operation procedures such as straw burial and land preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com