Production method of novel sea buckthorn all-fruit powder

A production method and technology of fruit powder, which is applied in the direction of pharmaceutical formula, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems not involved in the deep processing of seabuckthorn fruit, and achieve the effect of highlighting technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

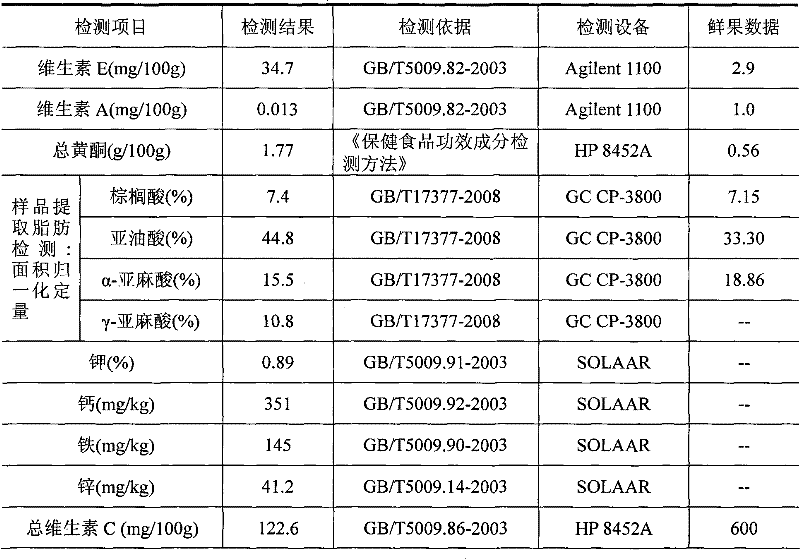

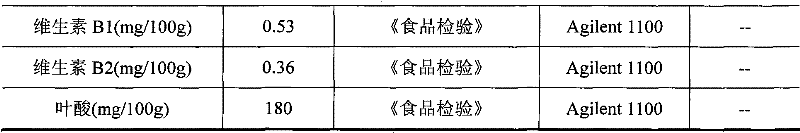

Image

Examples

Embodiment

[0019] Production of seabuckthorn whole fruit powder:

[0020] ① Selected fresh fruit or quick-frozen sea buckthorn fruit;

[0021] ② Use the original Taiqi air-induced pulverizer of model FDU DUTPUT-2HP to carry out pulverization. At this time, the weight-to-volume ratio of pulverized materials to liquid nitrogen is 1:4;

[0022] ③ Put the viscous pasty paste in the previous step into a vacuum drying oven for vacuum drying, the vacuum degree is below -0.09Mpa, the temperature does not exceed 50°C, and the time is about 12 hours;

[0023] ④ Repeat the low-temperature freezing and pulverizing process for the dried material again (conditions are the same as ②), and after becoming a fine powder, combine the materials twice;

[0024] ⑤ Sieve the material from the previous step through 80-100 mesh to obtain whole seabuckthorn fruit powder.

[0025] The use of the secondary freezing and pulverizing technology of the present invention realizes the process of directly turning seabuc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com