Glass reinforced plastic ribbed sand-included tube and manufacture method thereof

A manufacturing method and technology of FRP, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of fiber tensile damage, shedding, heavy pipe weight, etc., and achieve enhanced internal and external bonding and good toughness and elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

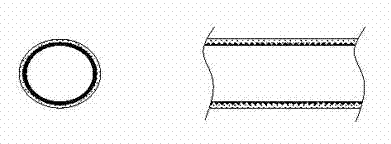

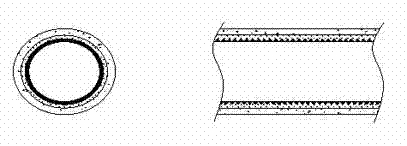

[0021] see Figure 1A to Figure 1C as well as figure 2 , The FRP reinforced sand-filled pipe proposed by the present invention is composed of a plastic reinforced inner liner 1, a sand-filled reinforced protective layer 2, and an outer winding protective layer. The plastic reinforced inner lining is made of raw materials such as PVC, PE or PP through an extruder to manufacture a reinforced strip with a lock, and then wound through a mold to form a plastic reinforced inner lining of the pipeline. After the lining is completed, 20~80 mesh quartz sand and unsaturated polyester resin or epoxy resin are premixed and wrapped with sand cloth, then spirally wound on the plastic reinforced inner lining to form a reinforced protective layer with sand inclusions, and then use resin-soaked The glass fiber is spirally wound to form an outer winding protective layer. In the fixed-length winding process, the socket is wound at the same time. It is cured at room temperature or infrared. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com