Heat-preservation compound glass steel tube and forming process thereof

A glass steel pipe and thermal insulation composite technology, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of high requirements on pipeline manufacturing process and lack of thermal insulation effect, and achieves good thermal insulation performance and combination of inside and outside. Enhanced force and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

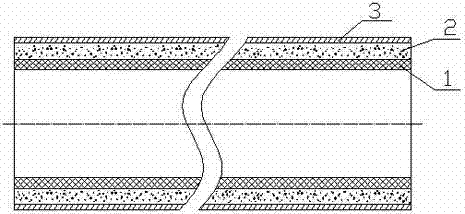

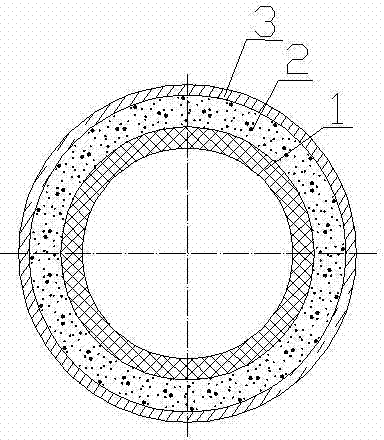

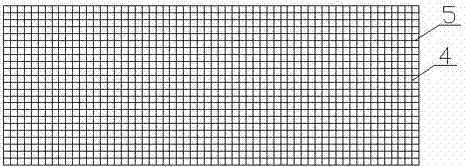

[0032] Insulation composite glass steel pipes, made of glass steel pipes, such as Figure 1~3 As shown, the glass steel pipes are respectively an inner winding layer 1, an insulation layer 2, and an outer protective layer 3 from the inside to the outside. First, the hoop glass fiber yarn 4 and the longitudinal glass fiber yarn 5 are cross-laid into a glass mesh, and resin is brushed on the glass mesh. , repeat the above steps until the thickness requirements of the FRP are met, on this basis, further processing can make the inner winding layer 1 . Such as image 3 As shown, the hoop glass fiber yarns 4 in the inner winding layer 1 are distributed along the circumference of the pipe, and the longitudinal glass fiber yarns 5 are parallel to the axis of the glass steel pipe.

[0033] Such as Figure 4 As shown, the insulation layer 2 is formed by using polyurethane foam as the base material, supplemented with a small amount of resin, mixed and coated on the outer wall of the in...

Embodiment 2

[0036] The forming process of thermal insulation composite glass steel pipe is shown in Table 1. The specific production process is as follows:

[0037] Mold preparation and glue dispensing: First, paint a resin mixture consisting of 55% (weight percent) epoxy resin and 45% (weight percent) polyamide on the mold, after 12 hours at room temperature until it is not sticky, scrape off the resin Mixture putty.

[0038] Making the inner winding layer: Lay a layer of fiber fabric cut according to the requirements on it, that is, hoop glass fiber yarn, press the fabric with a brush, roller or scraper to make it evenly impregnated and remove air bubbles, and then coat Brush the resin mixture and lay the second layer of fiber fabric, that is, the longitudinal glass fiber yarn; repeat the above process until the required thickness is reached; then, heat and solidify at a temperature of 60°C and a pressure of 0.1MPa and then cool to room temperature. After demolding, the fiberglass inne...

Embodiment 3

[0041] The forming process of thermal insulation composite glass steel pipe, the specific production process is as follows:

[0042] Mold preparation and glue dispensing: First, paint a resin mixture consisting of 60% (weight percent) epoxy resin and 40% (weight percent) polyamide on the mold, after 18 hours at room temperature until it is not sticky, scrape off the resin Mixture putty.

[0043] Making the inner winding layer: Lay a layer of fiber fabric cut according to the requirements on it, that is, hoop glass fiber yarn, press the fabric with a brush, roller or scraper to make it evenly impregnated and remove air bubbles, and then coat Brush the resin mixture and lay the second layer of fiber fabric, that is, the longitudinal glass fiber yarn; repeat the above process until the required thickness is reached; then, heat and solidify at a temperature of 100°C and a pressure of 0.1MPa and then cool to room temperature. After demolding, the fiberglass inner winding layer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com