Liquid crystal alignment composition and method for manufacturing liquid crystal display device

A liquid crystal display device, a technology for liquid crystal alignment, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of inability to reduce complexity and cost effectively, save the cost of machinery or consumables, and avoid the rate of product quality. The effect of lowering and lowering production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

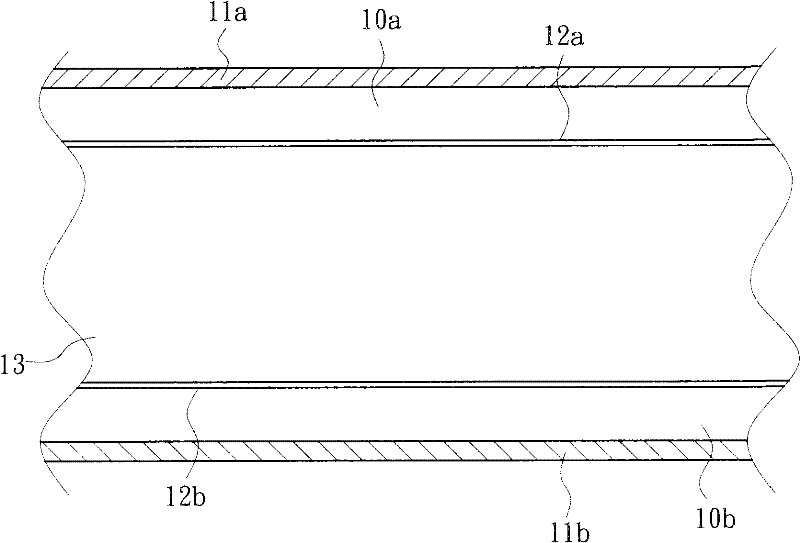

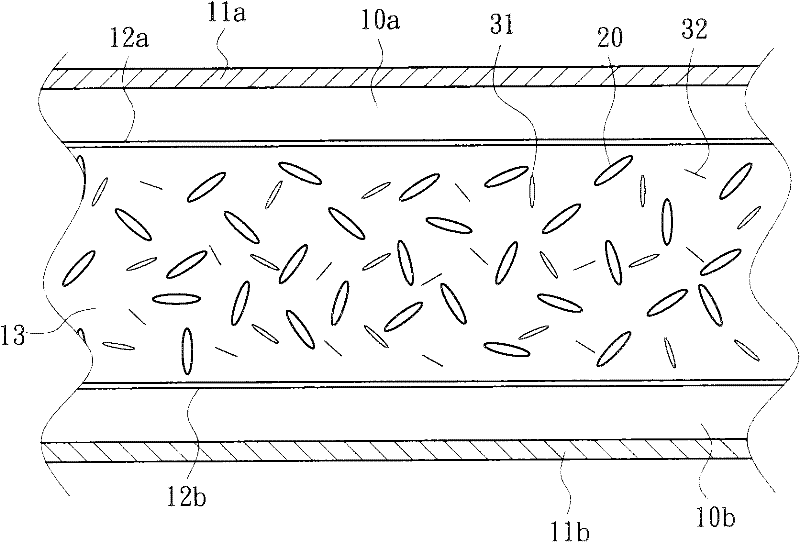

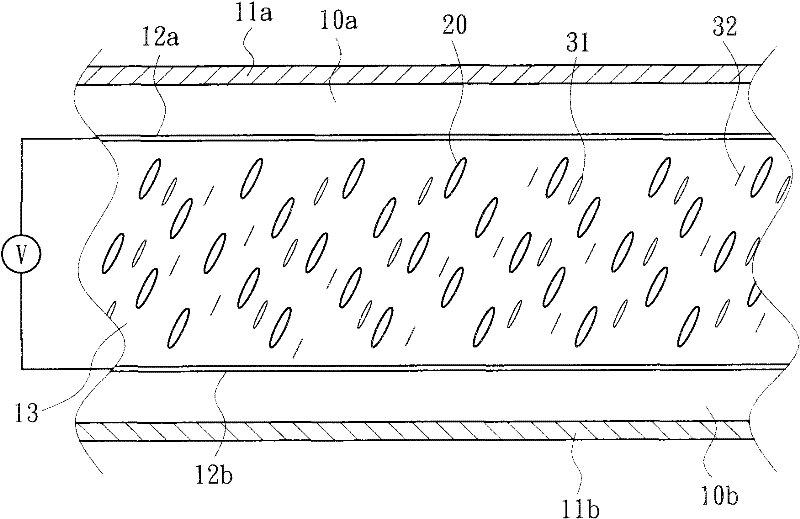

[0037] Relevant detailed description and technical contents of the present invention are as follows with regard to coordinating accompanying drawings now:

[0038] The invention discloses a liquid crystal alignment composition, comprising a heterocyclic monomer of the following formula (I) and an acrylic monomer of the following formula (II);

[0039] The heterocyclic monomer of the formula (I):

[0040]

[0041] Among them, R 1 , R 2 , R 3 Respectively selected from the group formed by the following formula (I-a), formula (I-b), formula (I-c) and formula (I-d) functional groups, the R 1 , R 2 , R 3 Functional groups that can be the same, different or partly the same:

[0042]

[0043] Among them, n is an integer ≥ 0, m is an integer ≥ 1, X 1 is hydrogen or methyl; and

[0044] The acrylic monomer of the formula (II):

[0045]

[0046] Among them, l is an integer ≥ 1, the X 2 For hydrogen or methyl.

[0047] The mixing weight ratio of the aforementioned het...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com