Method for raising cyclic thermal performance of gas turbine based on combustion-reforming of methane

A gas turbine, methane combustion technology, applied in the direction of gas turbine devices, climate sustainability, chemical instruments and methods, etc., can solve the problems of increased heat loss of gas turbine exhaust, reduced thermal efficiency of gas cycle, high NOx emission concentration, etc., to achieve design The effects of compact structure, increased specific power, and improved cycle thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

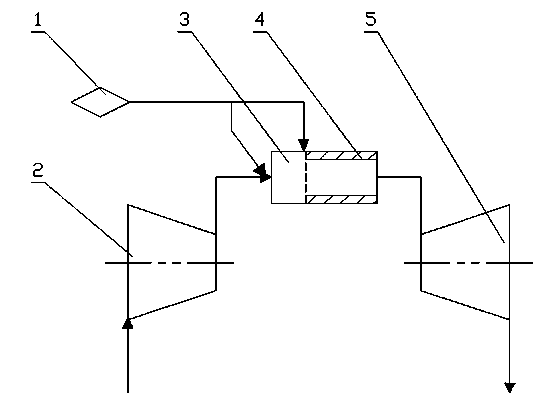

[0016] A method for improving the thermal performance of a gas turbine cycle based on methane combustion-reforming, the method adopts such as figure 1 The shown device comprises the steps of:

[0017] 1) Pass the air pressurized by the compressor 2 in the gas turbine and a part of the fuel flow 1 into the combustion chamber 3 of the gas turbine, and burn in the combustion chamber 3 of the gas turbine (chemical reaction formula: CH 4 +2O 2 =CO 2 +2H 2 O), forming H 2 O and CO 2 The mixed gas, in addition to N in the flue gas 2 In addition, a large amount of CO 2 and H 2 O component.

[0018] 2) Combine a part of the fuel flow with the H produced by combustion 2 O and CO 2 In the combustion chamber 3 of the gas turbine, the catalyst surface 4 continues to undergo an endothermic reforming reaction, absorbing the high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com