Method for scheduling flow shop based on multi-swarm hybrid particle swarm algorithm

A hybrid particle swarm and workshop scheduling technology, applied in the computer field, can solve problems such as inability to overcome local search capabilities, fast evolution of PSO, and reduce population diversity, achieving strong local search capabilities, overcoming poor local search capabilities, and good scheduling The effect of the program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

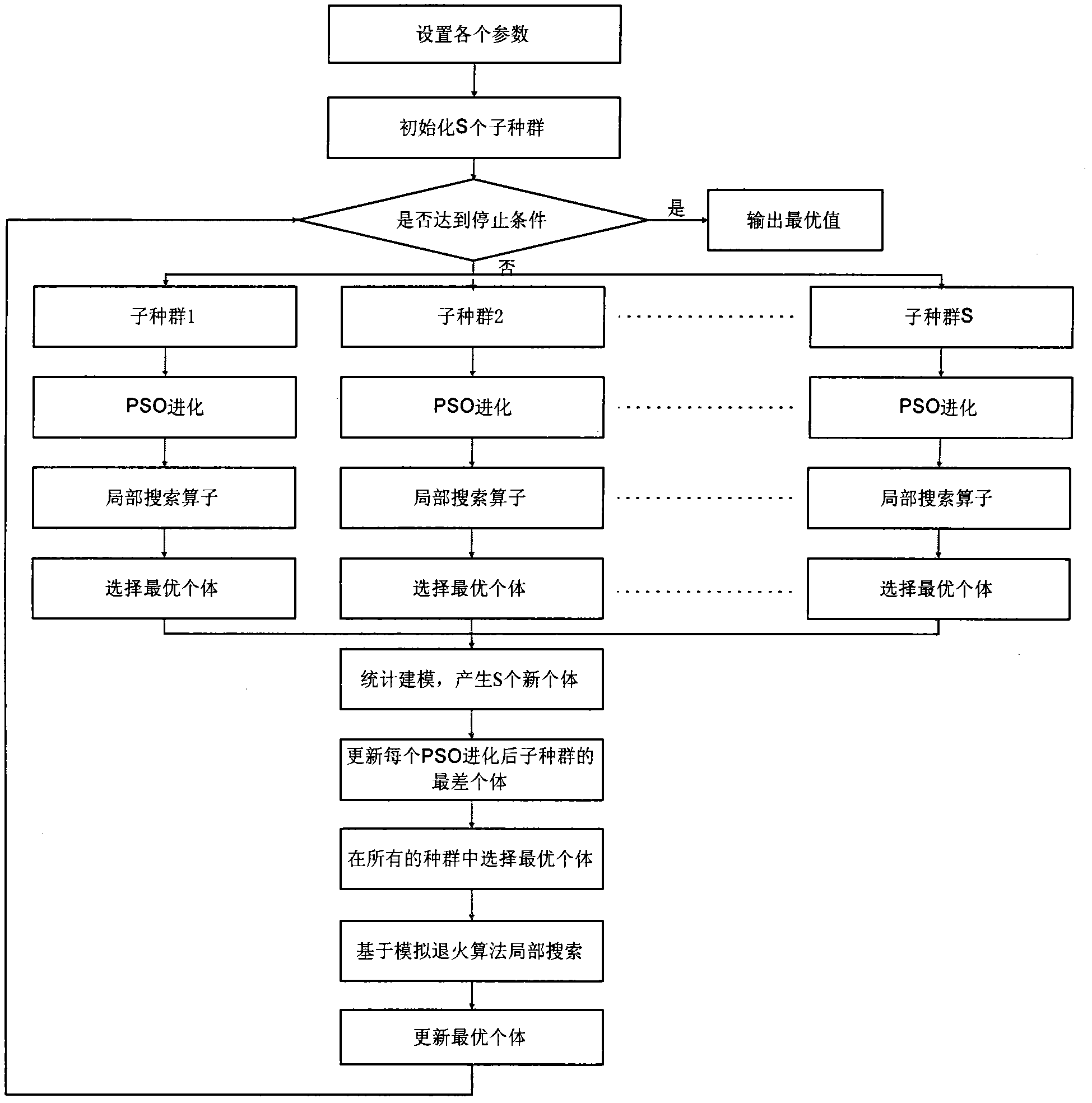

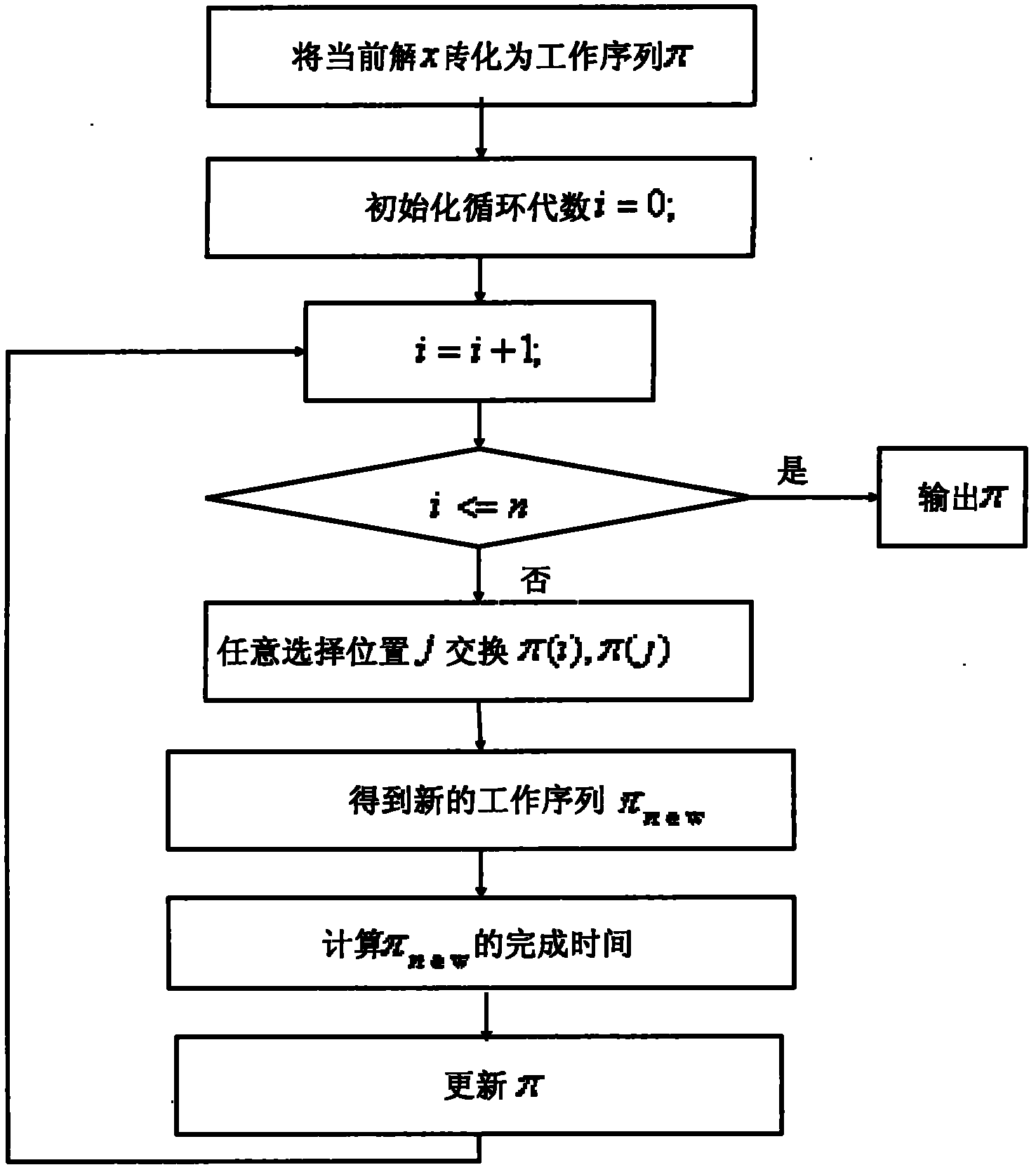

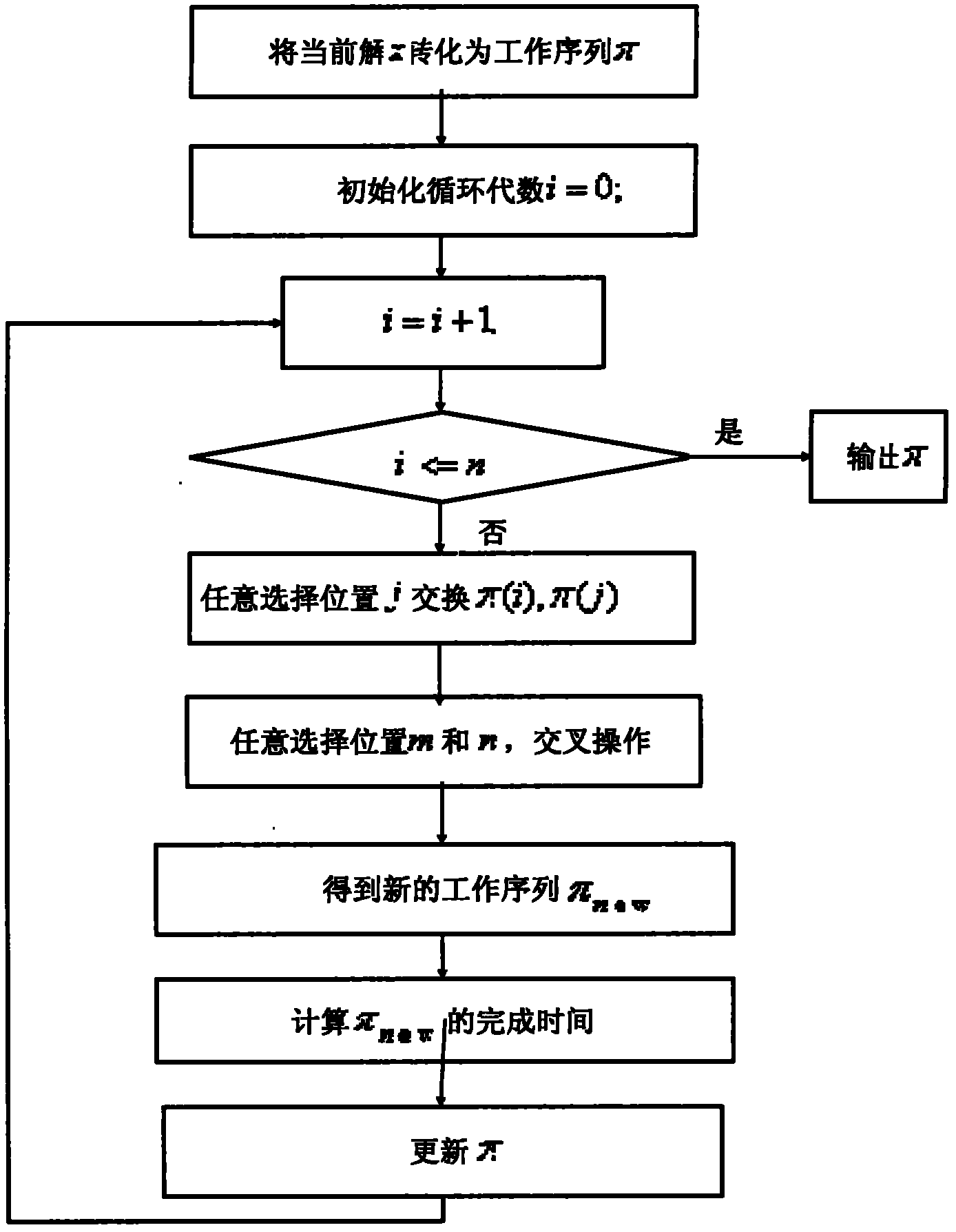

[0062] The present invention is a flow shop scheduling method based on multi-group mixed particle swarm algorithm, referring to figure 1 , including the following steps:

[0063] Step 1: Set parameters, the set parameters include: the maximum number of iterations of the program running t max , the number of scheduled jobs n, the number of machines m, the number of sub-populations S (when the number of jobs to be scheduled is large, S is relatively large), the maximum value of the particle position x max and minimum x min , the initial temperature T of the simulated annealing algorithm 0 , the annealing coefficient d, the use probability r1 of local search operator 1, the use probability r2 of local search operator 2, and define the fitness value f=T of particle A, where T is the corresponding scheduling scheme after decoding the position vector of particle A Scheduling time, initialize i=1;

[0064] Step 2: Generate the initial population Q, and divide the initial populati...

Embodiment 2

[0117] Simulation

[0118] The flow shop scheduling method based on the multi-population mixed particle swarm algorithm is the same as embodiment 1, and the effect of the present invention can be further illustrated by the following experiments:

[0119] 1. The standard test data set used in the simulation experiment

[0120] The present invention simulates and tests 26 flow shop scheduling problems, the first 8 problems are proposed by Carlier, and the other 18 problems are proposed by Reeves. These questions are commonly used test questions by scholars to study the flow shop scheduling problem. Among them, C in the table is the optimal time for each problem obtained so far.

[0121] 2. The parameter setting conditions of the simulation experiment:

[0122] The settings of the parameters involved in the present invention are as follows: the number of subpopulations S=3, the inertia weight w=1.0, the learning factor c1=c2=2.0, the minimum value xmin=-4.0 of the particle pos...

Embodiment 3

[0136] The flow shop scheduling method based on the multi-population mixed particle swarm algorithm is the same as that of Embodiment 1, and its parameter setting is the same as that of Embodiment 2. The proposed method (MPSOMA) is compared with the existing statistical learning-based particle swarm algorithm (PSOEDA) to verify the effectiveness of the introduced local search operator.

[0137] It can be seen from Table 2 that the present invention adopts multiple local search operators, and compared with the existing method PSOEDA, it has achieved better average values on most of the problems. The invention can reasonably arrange the work sequence, use less completion time, and effectively improve the production efficiency of the flow workshop.

[0138] Table 2 The method (MPSOMA) of the present invention and the result contrast of PSOEDA

[0139]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com