Method for synchronously extracting soybean oil and protein concentrate

A technology for concentrating protein and soybean oil, which is applied in the direction of edible oil/fat, protein food ingredients, protein composition of vegetable seeds, etc., can solve the problems of post-processing difficulties, use restrictions, protein loss, etc., and achieve the improvement of free oil yield , high ethanol recovery rate and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0044] Experimental example 1 Screening experiment of optimum parameters of ethanol cold bath process conditions

[0045] 1 Materials and methods

[0046] 1.1 Materials and reagents

[0047] Absolute Ethanol Tianjin Tianli Chemical Reagent Co., Ltd.

[0048] 1.2 Main instruments and equipment

[0049] Electronic Analytical Balance Merlot-Toledo Instruments (Shanghai) Co., Ltd.

[0050] Low-speed centrifuge Anhui Zhongke Zhongjiaxue Instrument Co., Ltd.

[0051] Desktop high-speed refrigerated centrifuge Beijing Jingli Centrifuge Co., Ltd.

[0052] Low temperature and constant temperature stirring reaction bath Zhengzhou Great Wall Technology Industry and Trade Co., Ltd.

[0053] Semi-automatic azotometer Shanghai Xinjia Electronics Co., Ltd.

[0054] Digester Shanghai Fiber Inspection Instrument Co., Ltd.

[0055] Soxhlet Extractor Tianjin Glass Instrument Factory

[0056] 1.3 Experimental method

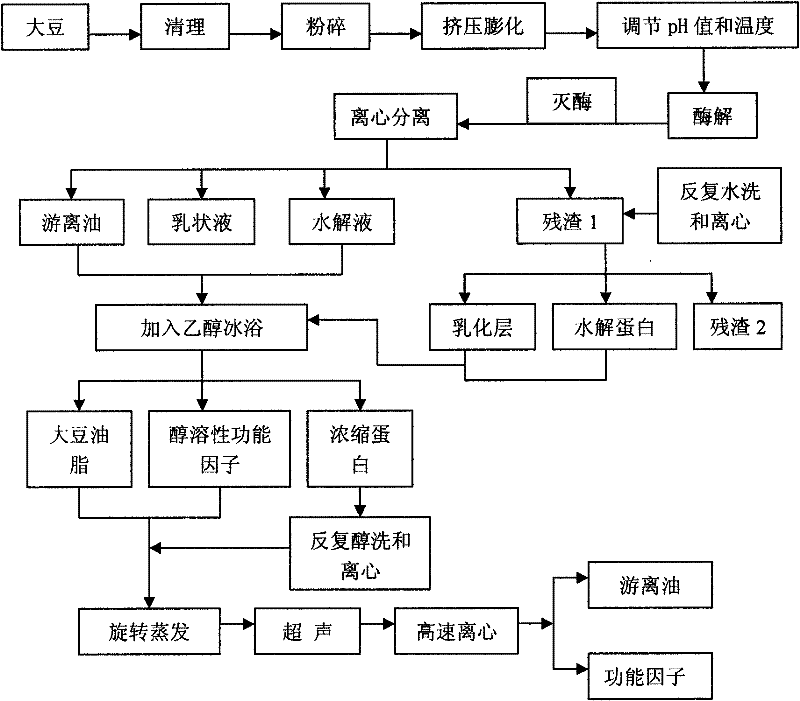

[0057] 1.3.1 Process flow (see figure 1 )

[0058] 1.3.2 Calculation...

experiment example 3

[0147] Experimental example 3 Screening experiment of optimal parameters of ultrasonic process conditions

[0148] 1 Materials and methods

[0149] 1.1.1 Main instruments and equipment

[0150] Ultrasonic Cell Disruptor Ningbo Xinzhi Biotechnology Co., Ltd.

[0151] 1.3 Experimental method

[0152] 1.3.1 Process flow (see figure 1 )

[0153] 1.3.2 Calculation formula

[0154]

[0155] 2 Results and Discussion

[0156] 2.1 Effect of single factor condition of ultrasonic process on the yield of free oil

[0157] 2.1.1 Effect of ultrasonic temperature on the yield of free oil

[0158] The ultrasonic time is 50s, the ultrasonic power is 400W, and the influence of ultrasonic temperature on the yield of free oil is investigated. The results are shown in Figure 22 . Depend on Figure 22 It can be seen from the results that the yield of free oil increases significantly when the ultrasonic temperature is higher than 50°C, but when the enzymatic hydrolysis time is greater ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap