Full-automatic machine for making milk from milk powder

A milk machine, fully automatic technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of too simple structure, inconvenient use, no warm water heating and cooling system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

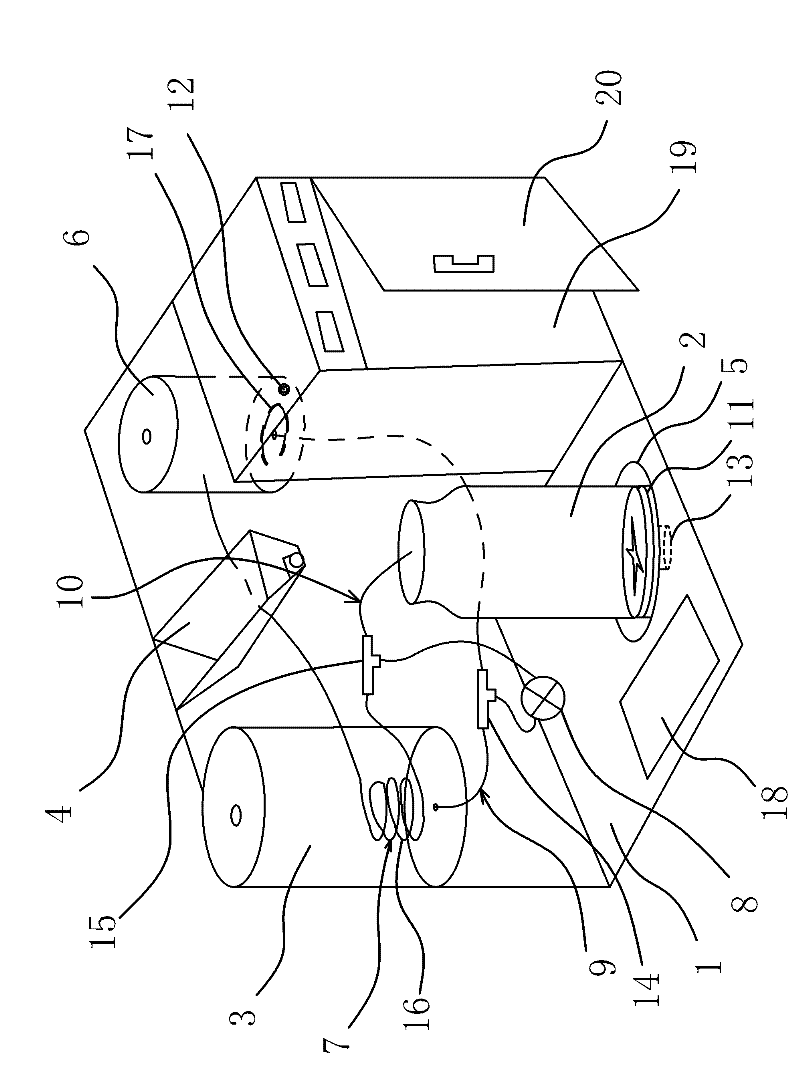

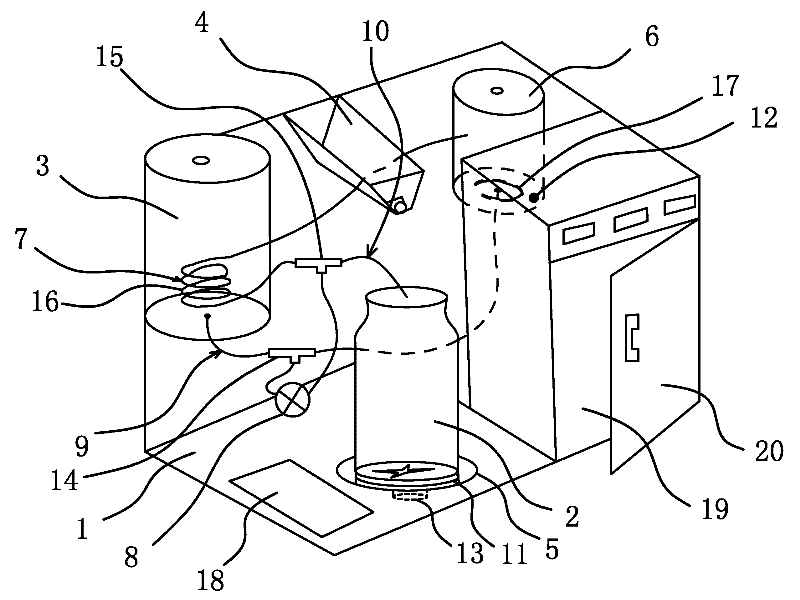

[0022] The following are specific embodiments of the present invention combined with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0023] Such as figure 1 As shown, the fully automatic milk preparation machine includes a base 1 and at least one milk bottle 2. The base 1 is provided with a water storage tank 3, a milk powder hopper 4, and a card position 5 capable of placing the milk bottle 2, and the card position 5 is located in the milk powder hopper. Directly below the injection port of 4, a heating cup 6 is provided on the base 1, and an electric heating wire 17 is provided on the inner surface of the bottom of the heating cup 6. The heating wire 17 is the most conventional heating method. The base 1 is also provided with a cooling device 7, a control valve assembly and a water pump 8, and a water receiving box 18 is provided directly below the water pump 8. Af...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap