Miniature A4 paper cutting machine

A paper cutter, small-scale technology, applied in the direction of winding strips, sending objects, stacking receiving devices, etc., can solve the problems of unfavorable large-scale production, high investment cost, occupation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

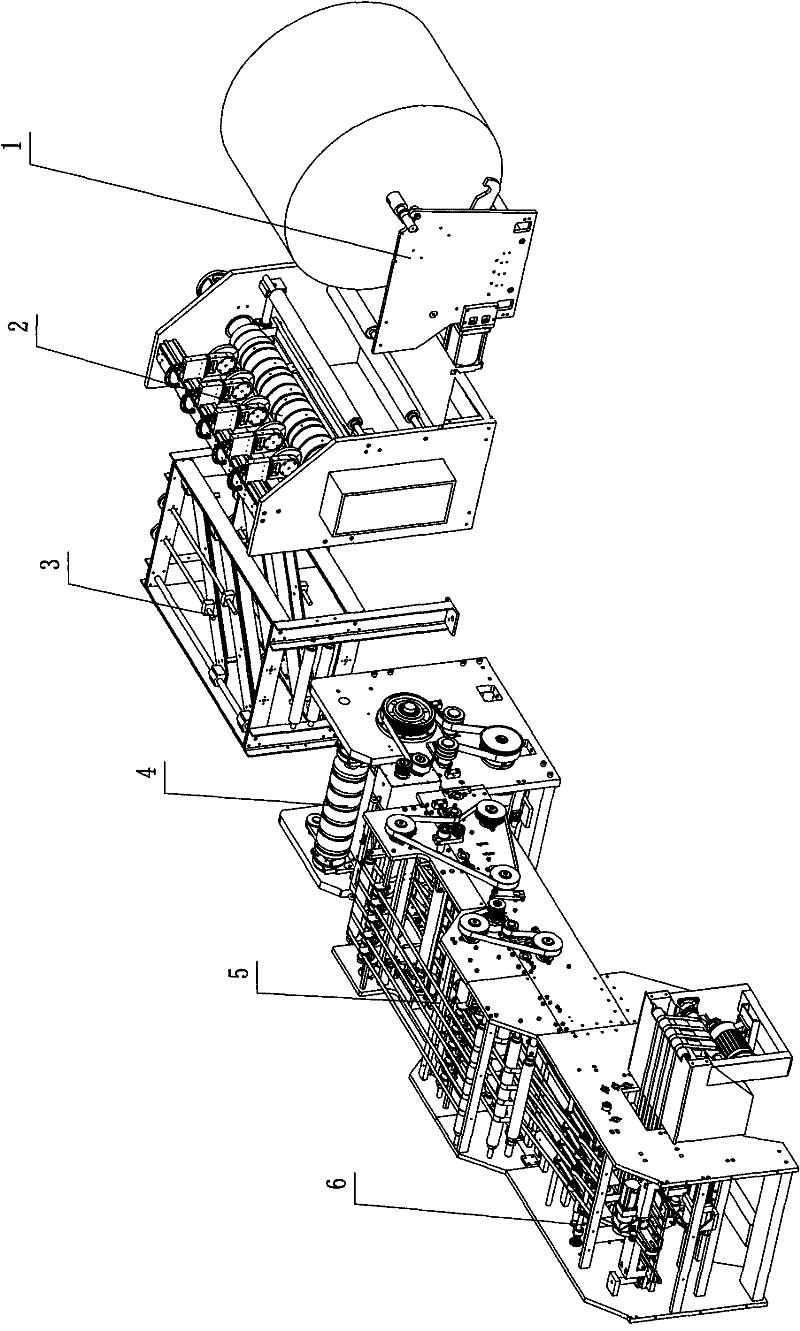

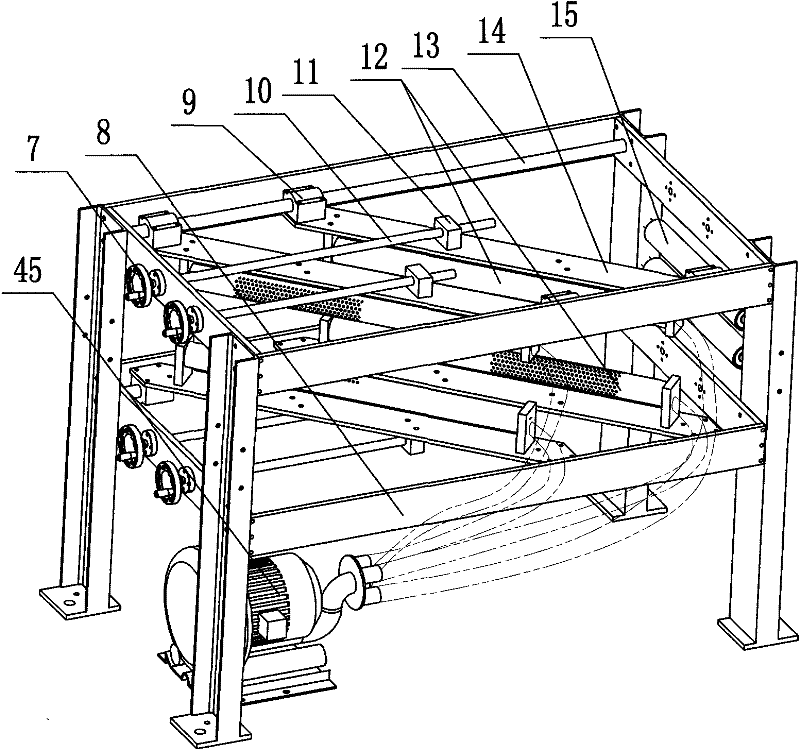

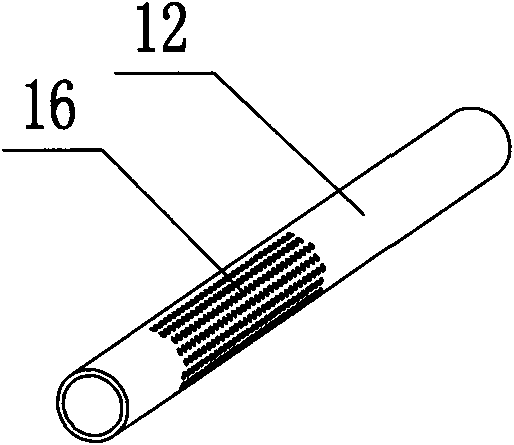

[0021] With reference to the accompanying drawings, this small A4 paper cutter includes a paper discharge device 1, a slitting device 2, a paper turning device 3, a crosscutting device 4, a paper feeding device 5 and a paper delivery device 6, and the paper discharge device 1 , slitting device 2, paper turning device 3, cross-cutting device 4, paper feeding device 5 and paper delivery device 6 are placed in sequence, and the specific structure of each device is described below; the external shape of described paper turning device 3 is a cube, After the slitting device 2 and the paper delivery device 1 are placed in parallel, the slitting device 2 is close to the lateral side of the paper turning device 3, and the cross-cutting device 4, the paper feeding device 5 and the paper delivery device 6 are placed in a row in sequence, And the cross-cutting device 4 is close to the longitudinal side of the paper turning device 3, so that the slitting device 2 and the cross-cutting devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com