Active heave compensation device for releasing and assembling deep sea winch

A technology for heave compensation and installation, which is applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of increasing difficulty and challenge of active heave compensation device, save the cost of offshore construction operation, simple structure of hydraulic mechanism, The effect of the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

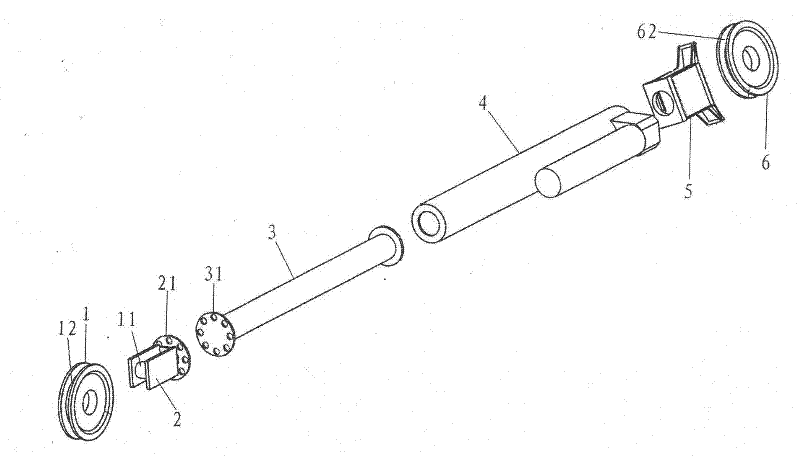

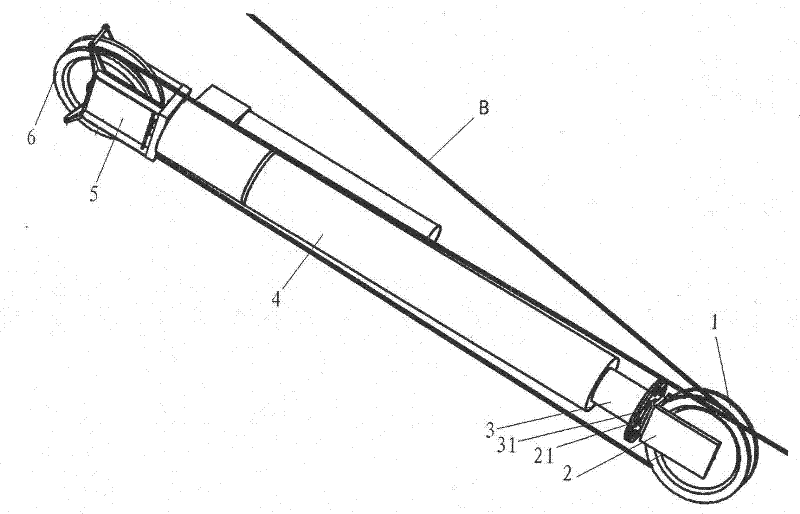

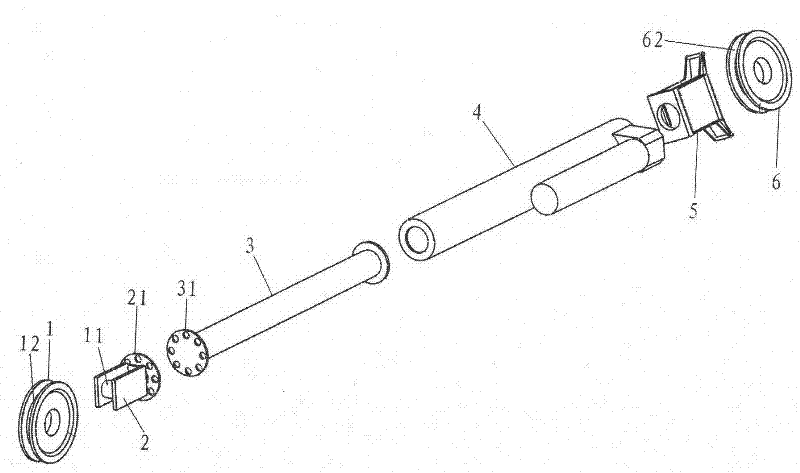

[0013] like figure 1 , figure 2 As shown, the deep water winch of the present invention is lowered and installed with an active heave compensation device, which includes a movable pulley 1, a movable pulley fixed frame 2, a piston rod 3, a hydraulic cylinder 4, a fixed pulley fixed frame 5, and a fixed pulley 6; There is a piston, and the piston is nested in the cylinder body of the hydraulic cylinder 4, so that the piston and the inner wall of the cylinder are sealed by hydraulic oil to form a hydraulic actuator; the movable pulley 1 is installed on the movable pulley fixed frame 2, and the movable pulley fixed frame 2 and the piston The end of the rod 3 away from the piston is connected; the fixed pulley 6 is installed on the fixed pulley fixed frame 5, and the fixed pulley fixed frame 5 is connected with the bottom of the hydraulic cylinder.

[0014] like figure 1 , figure 2 As shown, the active heave compensation device for lowering installation of the deep water winc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com