Modified bitumen waterproof coiled material and production method thereof

A technology of waterproofing membrane and modified bitumen, which is applied in the direction of roofing, building insulation material and building components using flexible materials, which can solve the problems of increasing the cost and increasing application of bituminous waterproofing membrane products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

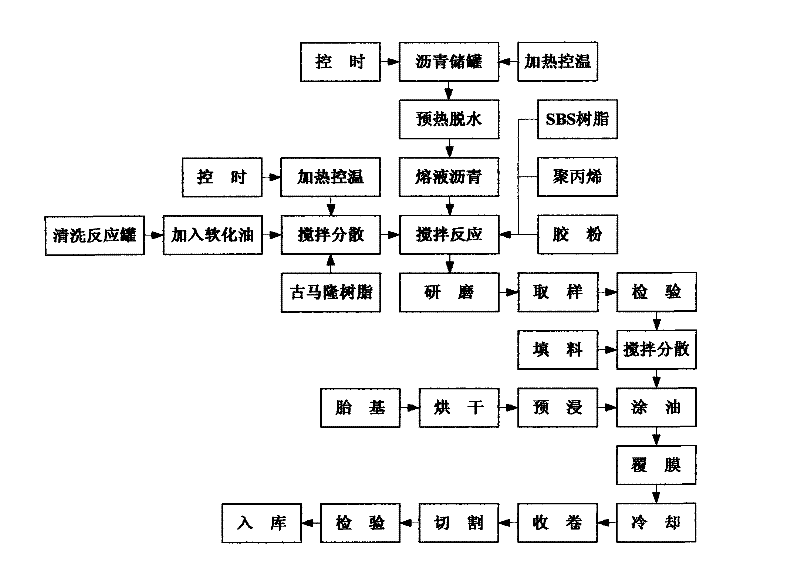

[0093] according to figure 1 Shown production process flow, produce a kind of low-cost modified asphalt waterproof membrane of the present invention, concrete method is as follows:

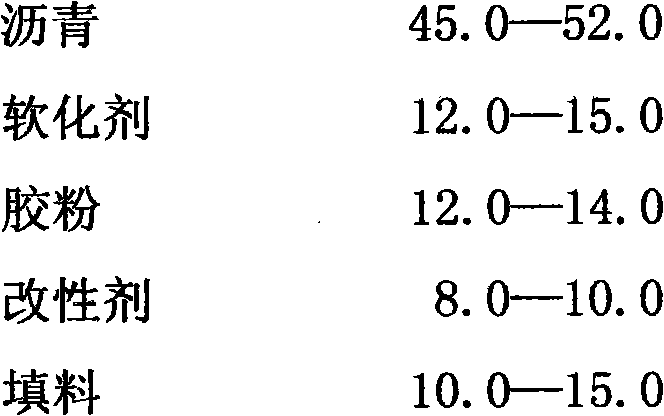

[0094] A. raw material composition (weight part)

[0095]

[0096] B. Production method

[0097] The production method is carried out in the following steps:

[0098] 1). First, clean the reaction tank. At the same time, do a good job in all preparatory work before starting the machine, and confirm that it has fully met the requirements of safe production. Open the heating valves of the 10# and 90# asphalt storage tanks, preheat and dehydrate the asphalt in the storage tanks for later use.

[0099] 2). Open the heating valve of the reaction tank to heat. Pour the specified amount of softener into the reaction tank according to the ratio of the formula. Then, start the mixer and continue heating.

[0100] 3). When the temperature in the reaction tank reaches 120°C, add the specified amoun...

Embodiment 2

[0108] according to figure 1 Shown production process flow, produce a kind of low-cost modified asphalt waterproof membrane of the present invention, concrete method is as follows:

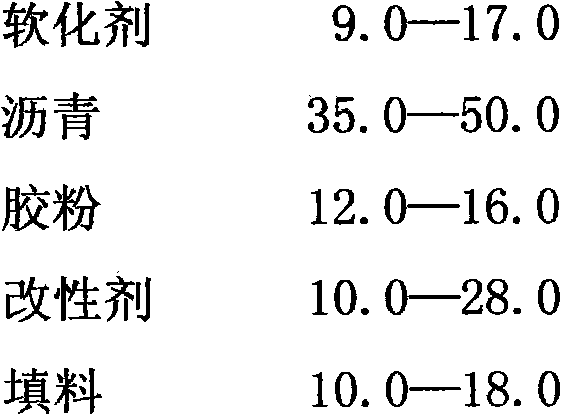

[0109] A. raw material composition (weight part)

[0110]

[0111] B. Production method

[0112] The production method is carried out in the following steps:

[0113] 1). First, clean the reaction tank. At the same time, do a good job in all preparatory work before starting the machine, and confirm that it has fully met the requirements of safe production. Open the heating valves of the 10# and 90# asphalt storage tanks, preheat and dehydrate the asphalt in the storage tanks for later use.

[0114] 2). Open the heating valve of the reaction tank to heat. Pour the specified amount of softener into the reaction tank according to the ratio of the formula. Then, start the mixer and continue heating.

[0115] 3). When the temperature in the reaction tank reaches 120°C, add the specified amoun...

Embodiment 3

[0123] according to figure 1 Shown production process flow, produce a kind of low-cost modified asphalt waterproof membrane of the present invention, concrete method is as follows:

[0124] A. raw material composition (weight part)

[0125]

[0126] B. Production method

[0127] The production method is carried out in the following steps:

[0128] 1). First, clean the reaction tank. At the same time, do a good job in all preparatory work before starting the machine, and confirm that it has fully met the requirements of safe production. Open the heating valves of the 10# and 90# asphalt storage tanks, preheat and dehydrate the asphalt in the storage tanks for later use.

[0129]2). Open the heating valve of the reaction tank to heat. Pour the specified amount of softener into the reaction tank according to the ratio of the formula. Then, start the mixer and continue heating.

[0130] 3). When the temperature in the reaction tank reaches 120°C, add the specified amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com