White light LED with uniform color temperature and high color rendering performance

A high color rendering, LED chip technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as non-conformity with lighting standards, unevenness of color temperature space angle, and bluish central light emission of LEDs, etc., to eliminate lateral Yellowish luminous effect, good consistency, uniform angle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment, further illustrate the present invention.

[0024] The specific implementation steps are as follows:

[0025] 1. Preparation of fluorescent sheet 7:

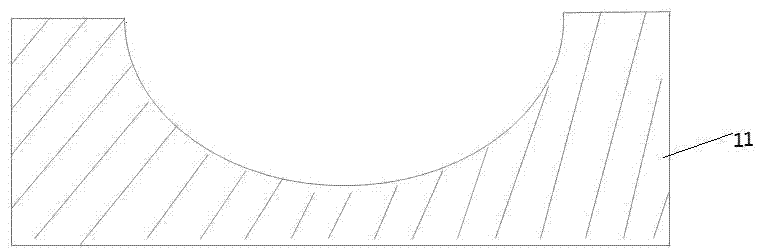

[0026] (1) Prepare a spherical groove mold 11 by mechanical processing, the shape and size of the groove are as follows figure 1 shown.

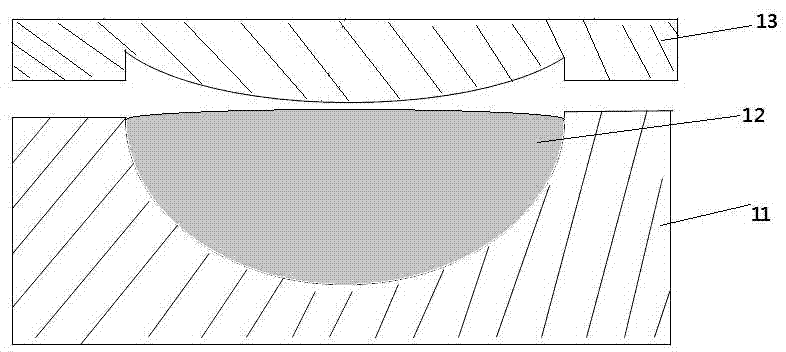

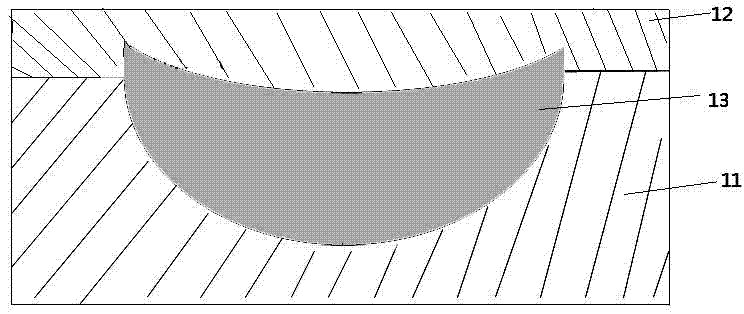

[0027] (2) Prepare the spherical convex groove mold 13 by mechanical processing, the shape and size of the convex groove are as follows: figure 2 shown.

[0028] (3) Prepare glue A and B according to the mass ratio of components A and B at 1:1, add yellow phosphor to AB glue, phosphor and AB glue at 0.08—0.12 g / cm 3 Proportional preparation, stirring, uniform dispersion, and preparation of fluorescent glue.

[0029] (4) Drop the fluorescent glue prepared in step 3 into figure 1 In the shown spherical groove mold 11, forming figure 2 Fluorescent glue 12 shown.

[0030] (5), such as figure 2 As shown, the spheri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com